thyssenkrupp unveils, celebrates the first fully functional MULTI elevator system at its Rottweil, Germany, test tower.

More than 200 elevator-industry experts, high-profile developers, architects, engineers and journalists from around the world convened June 22 at the thyssenkrupp Elevator innovation test tower in the historic, picturesque town of Rottweil, Germany, for the unveiling of what’s being called a game changer in the world of elevatoring, the MULTI. A ropeless and vertical-and-horizontal-moving elevator system, MULTI conjures everything from the paternoster and linear-motor systems of the past to TK’s more recent revelation, the TWIN, then pushes past all of them to offer their refined culmination.

Instead of one cabin per shaft moving up and down, MULTI features multiple cabins operating in a loop, like a metro system inside a building, according to TK. Without the use of cables, MULTI runs on a multilevel brake system and redundant wireless data and energy management on the cars. Three years in development, the concept was first presented as a 3:1 scale model at TK’s Innovation Center in Gijón, Spain, in late 2015. In Rottweil, the system finally turned into a reality as TK launched the first fully functional MULTI unit at its much-anticipated unveiling event.

Under a spacious white tent set up adjacent to the test tower, guests filed in midmorning after mingling and enjoying drinks and hors d’oeuvres outside. The anticipation that had begun for many guests, your author included, at a TK-hosted dinner the night before increased as high-energy music flowed through large speakers strategically placed throughout the tent. The back of the room stood lined with video cameras, camera operators, lighting and sound equipment and reporters. As the seats filled, large TV screens on either side of the stage showed cityscapes with tall buildings and busy highways. In the center, above the stage, the largest screen welcomed us.

At the previous night’s dinner, over stellar German food and beer at Rottweil’s Wandelbar Restaurant and with the twinkling lights of the 246-m-tall test tower in the background, my dinner companions and I pondered MULTI and its implications: would it, quickly or over time, change the flow of traffic in, and the design of, tall buildings around the world? Would it make the movement of patients through hospitals simpler? Would it save space and time? Would banks buy into such a new concept and lend money to those who wanted to implement it? Was MULTI really the future, and, if so, would the industry be ready for it? The chatter slowed on the long and late bus ride back to the various hotels TK’s guests filled in and near Rottweil, but the curiosity and excitement had been well established.

So, the morning of the unveiling, when Ben Hammersley, editor-at-large for Wired magazine and a futurist, walked onto the stage, the crowd was humming, the energy palpable. Hammersley opened the event by discussing concepts that had changed the modern world – the automobile, the microchip, HTML – all of which he called “enabling, transformative technologies.” According to Hammersley, enabling technologies are categories of technologies that inform and enable the next generation of technologies. “Today, we live in a society that is underpinned by all of these enabling technologies — tools that can get twice as good every year. We are here today to learn about another enabling technology that will change the shape and culture of cities,” he said, stopping short of naming MULTI as he introduced Andreas Schierenbeck, CEO of thyssenkrupp Elevator.

From my point of view, ropeless elevators (thus MULTI, but any other cable-free elevator, no matter what is the propulsion technology) will have a dramatic impact on the way buildings, and tall buildings, are designed. For 160 years, elevators have gone up and down in a vertical shaft, and this has been the bottom line for every building taller than 3 to 2 stories, no matter its function, shape, construction material, cost, etc. So, this has become a fundamental part of the DNA of all buildings, and thus of all cities. Changing this means altering the DNA of an organism, opening endless design possibilities that architects still have to understand and develop. They will be the real “obstacle” in the successful implementation of ropeless elevators. They need to change the way they think of and design buildings.

Almost three years ago, the development of MULTI began in answer to the burgeoning migration of people to cities, Schierenbeck said. This is a massive challenge for mankind, he explained; it is a challenge for space, energy and the timely movement of people. While the means to build taller buildings exist, without the ability to efficiently move the inhabitants of buildings between floors, the functionality of skyscrapers is limited, translating into loss of revenues if residential and commercial spaces on the topmost floors cannot be sold. In addition, 40% of usable space in an average high-rise building is currently taken by the elevators, explained Schierenbeck. With more people, we need to be able to access more space, he said, adding:

“Against this backdrop, it is clear that efficient mobility in buildings is no longer a luxury, but an absolute necessity. With limited land mass, buildings will have to get taller, and as a result, elevators can become a bottleneck. The right question in this case is not speed, but capacity. How to transport more people more quickly? First, we had the paternoster. Then, the TWIN, two cabins in one shaft. OK, but ropes are a problem. Maybe we should do something without ropes. We explored linear-motor technology. Then, we developed what’s become MULTI.”

According to Schierenbeck, among its attributes, MULTI provides:

- No limit on height

- Scalable transportation

- A reduced elevator footprint by 50%

- An increased capacity by 50%

- An up-to-75% reduction in peak power consumption

Schierenbeck concluded his talk saying, “An old era of elevators is coming to an end. A new era is beginning right here, right now.”

Dr. Antony Wood, executive director of the Council on Tall Buildings and Urban Habitat (CTBUH), created a wider context for MULTI when he took to the stage. Whereas tall buildings used to be office buildings being built predominantly of steel in North America, today’s tall buildings are of mixed use made with composite materials in the Middle East and Asia. Urbanization is the tall-building driver, with one city a week being developed for the next 30 years. According to Wood:

“We’ve had to overcome the shortfalls of tall – the ‘box’ commercial design approach and the ‘extreme icon’ approach. To get a good tall building today, you need to look at the climatic, cultural and social impacts. We need to consider the future, including things like drone use and vertical farming. MULTI frees up [a building’s] core and gets rid of ropes. It has the potential to not just change elevators, but the direction of cities.”

It was those elements of MULTI that attracted next speaker Coen van Oostrom, CEO of OVG Real Estate, a leading European real-estate company, to the product. Van Oostrom, no stranger to innovation and cutting-edge building construction, found inspiration years ago in U.S. Vice President Al Gore:

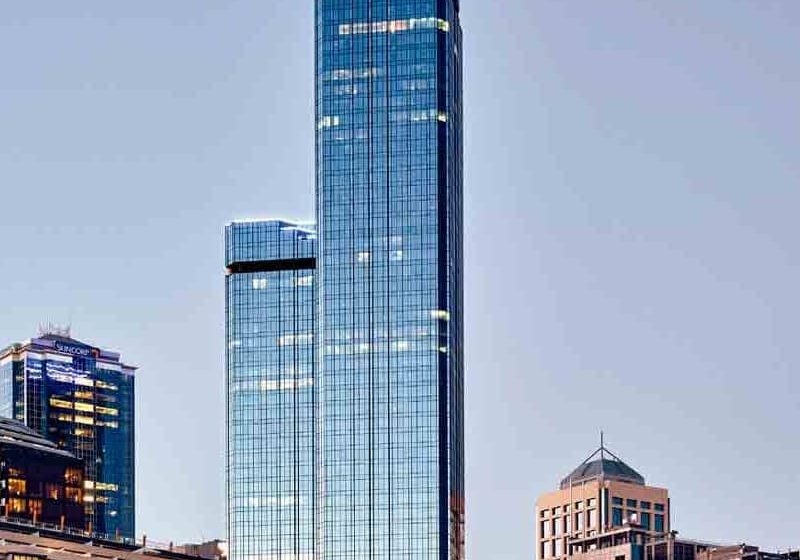

“He came and talked with me. He told me one-third of global warming comes from buildings, and we need to do what we can to slow down global polluting. So, in 2008, with Las Palmas in Rotterdam, we created the first energy-neutral building in the Netherlands. Al Gore was excited, and [former] U.S. President Bill Clinton came to help us open the building. Two years ago, we completed The Edge in Amsterdam, the world’s most sustainable building. With the under-construction East Side Tower in Berlin, we are looking to get more sustainable. We do not want a very tall building, but we want the core back. To do that, we will be the first in the world to use MULTI, and we are very excited about this.”

Van Oostrom’s announcement brought Schierenbeck back to the stage amid enthusiastic applause. Various MULTI systems will be installed in the mixed-use East Side Tower, set to open in 2020. The flagship project will “define new technology standards and offer an entirely new office space concept,” according to OVG.

Wood and Hammersley joined the others on stage, and Hammersley shed light on the next phase of MULTI’s launch. He asked guests to keep their seats as the four men moved off the stage with cameras following them and broadcasting their movements. “MULTI is the result of 77 patents and thousands of ideas,” said Hammersley, as the group proceeded to the test tower and the MULTI shaft, where the inaugural ride (minus a passenger, as TK is not ready for MULTI riders just yet) would commence. On the screen, following a countdown, the crowd witnessed the first MULTI launch, a full-sized car moving first vertically, then horizontally in a shaft.

Exciting though it was, the crowd was eager to witness the MULTI up close. With so many guests to contend with, TK employees became group leaders for the day and broke the crowd into sets of 20 or so, leading each to a different station. Guests would visit seven stations throughout the test tower over the course of the afternoon, each featuring a TK testing area or innovation, and some featuring food and drink. Stations included a HoloLens demonstration; a talk on the test tower, which is home to TK’s R&D Center in Germany, and the town of Rottweil; the machine room for the TWIN; a freefall shaft for brake testing and a mass damper for seismic testing; MULTI models from early research done by CTBUH and a sample lightweight MULTI cab; the tower’s observation deck with views of Rottweil, the Swiss Alps and the Black Forest; and, of course, MULTI.

The stations proved interesting and enlightening, with TK specialists manning each, explaining what guests were seeing and experiencing, and answering questions. It was the MULTI station, though, that brought out the cameras, produced the most questions, and had guests taking turns for an up-close look through the glass into the shaft and at the car.

As the day wound to a close, many boarded buses bound for Stuttgart and Zürich airports, while others headed to their respective hotels for a rest before dinner. Still others boarded a bus for a guided VIP tour of Rottweil. The wrap-up barbecue dinner held at the test tower that evening proved a relaxed, casual affair and just the right ending to a busy day full of revelations. The test tower’s next milestone comes in October, when its cladding will be in place, and the observation deck open to the public. With the launch of MULTI only the beginning of this system’s story, there will be more articles to follow as MULTI milestones are reached.

How MULTI Works

Operating on the basic premise of a circular system, such as a paternoster, MULTI uses ropeless linear technology to operate elevators, and a single loop can incorporate various cabins. With a targeted speed of 5 mps, the system will enable near-constant access to an elevator cabin every 15-30 s., with a transfer stop every 50 m. Passengers will experience reduced wait times, and the option of double entries on the ground floor improves ease of access in large buildings.

After thyssenkrupp’s first attempt to address these issues in 2002 with the TWIN elevator system, offering two cabins per shaft and a 30% increase in transport capacity, as well as a reduction in the elevator footprint by 30%, thyssenkrupp is now removing the suspension ropes and equipping elevator cabins with linear motors, transforming elevator systems into vertical mass-transit systems and increasing transport capacities by 50%.

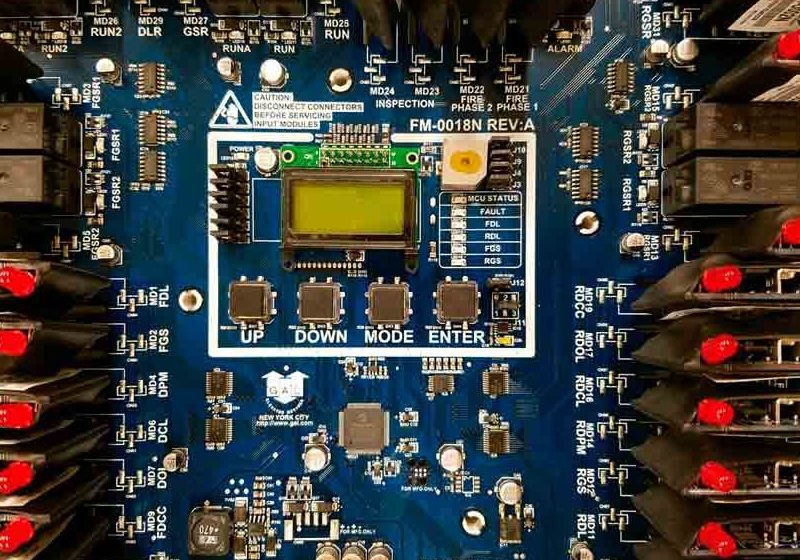

MULTI applies the linear-motor technology developed for the German magnetic-levitation train Transrapid to elevator cabins, enabling them to move in shafts in the same way trains move in rail systems, with various cabins per shaft, and permitting vertical, as well as horizontal, movements inside buildings. According to TK, safety is ensured by the multi-propulsion and braking systems in cabins, and the proven safety control system developed for the TWIN elevator technology that prevents cabins from getting too close to each other inside the shafts.

According to TK, MULTI also offers much higher capacities and faster and more comfortable movement as compared with high-speed elevators, which are limited by the effects of pressure on the human body, with many people experiencing discomfort while traveling in elevators at speeds higher than 10 mps.

Although the ideal building height for MULTI installations starts at 300 m, the system is not constrained by a building’s height. With no ropes, a multilevel brake system and wireless power transfers from shaft to cabin, MULTI requires smaller shafts of 6 m2, while other technologies, such as the TWIN, require about 9 m2. This can mean significant cost savings for the building’s developer, says TK. The overall increase in efficiency also translates into a reduced need for elevator shafts, thereby decreasing a building’s elevator footprint and providing further usable floor space and revenues to building owners.

While MULTI applies the concept of the TWIN’s control system and safety features, it includes new elements such as lightweight carbon composite materials for cabins and doors, weighing 50 kg instead of the 300 kg of standard elevators, resulting in an overall 50% weight reduction as compared to standard technologies. A new linear drive also enables one single motor to be sufficient to perform horizontal and vertical movements, and an exchanger moves cabins from one shaft to the other. According to TK, “by combining groundbreaking technology with a simple operation concept and convenience of passenger use, MULTI has transformed the idea of a flexible number of cars per shaft from a distant vision for the future into a reality.”

thyssenkrupp’s Innovation Test Tower

At a height of 246 m and a diameter of 21 m, the thyssenkrupp test tower in Rottweil, Germany, dominates the countryside. The company has invested more than EUR40 million (US$46.5 million) in the tower, and now has an advanced and ultramodern test center for new elevator concepts and technologies in one of Germany’s oldest cities.

The test tower has all that is needed for the development and testing of sophisticated elevator systems. It has 12 shafts in total, nine of which can be used as test shafts where engineers can conduct real-life runs with a top speed of 18 mps. In addition, there are test units for the TWIN elevator system and three test shafts reserved for the MULTI. Some shafts rise up to 200 m in height, nearly reaching the tower’s very top. However, others are much shorter and end at around 120 m. The space above these shorter shafts is used as an energy storage system where the thermal energy that results from engines and computers is captured and optionally returned via heat exchanger. The tower is not only a skyscraper, but a sustainable one.

The tower is closely connected to the TK elevator plant in nearby Neuhausen auf den Fildern, which employs approximately 1,500. The test tower features a conference floor, and 12 m above that lies Germany’s highest visitor platform, with a 360° panoramic view that includes the Swiss Alps and the Black Forest. A panoramic elevator brings visitors to the platform.

TK says the test tower is a statement for the company’s social responsibility and connection to the region. It gives Rottweil a new tourist attraction and has received a lot of support from local citizens and city administration – particularly because of the sustainable methods and concepts used while constructing the tower.

Get more of Elevator World. Sign up for our free e-newsletter.