Going Big in Buenos Aires

Feb 1, 2020

Mitsubishi Electric elevators take passengers to the top of Alvear Tower, Argentina’s tallest building

by Carmen Maldacena, EW Correspondent

Photos by Ascensores Heavenward

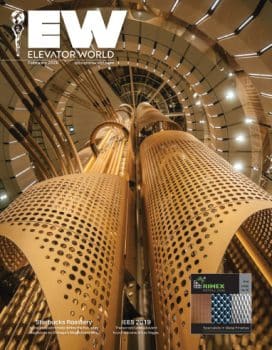

At 235 m, Alvear Tower is Argentina’s tallest building, bringing residences and a five-star-plus hotel to Puerto Madero, Buenos Aires’ newest and most expensive district. For vertical transportation, Ascensores Heavenward SA supplied and installed 14 Mitsubishi Electric elevators manufactured in Japan. Aside from its height, Alvear Tower became an immediate iconic landmark because of the original design by architects Pfeifer-Zurdo and the luxurious and comfortable amenities it offers.

Grupo Sutton — owners of the Alvear, Alvear Art and Plaza Hotels — broke ground for Alvear Tower in 2012, a construction project financed through an investment of approximately US$130 million. Argentine contractor Criba SA — responsible for the construction of such important buildings such as the Repsol-YPF Tower (ELEVATOR WORLD, September 2010) — carried out the construction, which was completed in August 2019.

The tower holds 79,000 m2 of space divided among 54 floors to create 160 3.3-m floor-to-ceiling apartments built around vertical circulation cores to take advantage of the roundish shape of the building. There are also two underground levels. The Roof Club, on the 54th floor, tops the tower and offers panoramic, breathtaking views of Buenos Aires and the River Plate.

Alvear Tower features a slate of amenities: a spa and gymnasium, a business center, outdoor and indoor swimming pools, cinemas, tennis courts, beauty salons, private wine cellars, a multipurpose room, golf and ski simulators, a car wash and a pet spa. Its impressive height brought complexities during construction. Criba used a self-climbing frame to enable the use of reinforced concrete. Project Director Santiago Tarasido explained the challenges:

“Towers in Argentina are built with reinforced concrete, so it is very difficult to pump it up over 100 m high. On the contrary, most high-rise towers in the world are built with iron, as if they were a Meccano toy. The architect, Pfeifer, found a solution: concrete was pumped up from the ground floor up to a repumping plant, located halfway up, using super-rapid cranes to lift the material. Intermediate lunch places were organized to avoid the up and down movement of workers at noon.”

Elevators to the Sky

Ascensores Heavenward, Mitsubishi Electric’s representative in Argentina, supplied and installed 14 NEXWAY elevators: 10 main duplex and four service duplex lifts. All were manufactured in Japan and use gearless permanent-magnet (PM) machines. Eight high-speed elevators travel at 4 m/s, but the two fastest lifts travel up to the top at 5 m/s. As for capacity, 10 of the units are rated at 750 kg (10 passengers), and the other four units, which provide the longest ride (232 m) are rated for 900 kg (12 passengers) and serve 54 stops. The units, which feature automatic energy-recovery systems, are remotely monitored from two control stations using Mitsubishi’s MelEye system.

The main elevators have cab interiors built in AISI 304 brushed-finish stainless steel with granite floors and feature 90-min fire-resistant car and landing doors. The service elevator cars are finished in stainless-steel “elephant skin” and diamond- shaped aluminum.

All the elevators are equipped with keypad car operating panels with floor access codes. The panels have buttons from 0 to 9 in a pad arrangement similar to a telephone and are combined with a restricted-access system. The user dials a four-digit pass number to access the destination floor. The floor number is shown on the key pad display to confirm a valid pass number has been entered, and the elevator then proceeds to the correct stop.

All elevators are equipped with fire evacuation and firefighter operation (Phase 1 and 2). Two of them feature a Shabbat function from Friday evening to Saturday morning. All the operating parameters of the Shabbat special feature are made possible via programmable controllers. The first elevators arrived in Buenos Aires in February 2015, and assembly started at the beginning of 2016. Work on the units was completed in 2017.

Get more of Elevator World. Sign up for our free e-newsletter.