In this Readers Platform, your author describes the link between modernizing elevators and retaining commercial tenants.

Scan the skyline in most U.S. cities these days, and you will likely see numerous cranes rising from commercial construction sites. So, it is fairly safe to speculate that owners of existing buildings will have to compete with even more new buildings for tenants. That is why it is crucial for such building owners to maintain their properties for their buildings to stay desirable. Modern, comfortable, efficient elevators are a key part of that equation.

Dodge Data & Analytics stated that, at the end of 2014, total U.S. construction starts for 2015 would rise 9% to US$612 billion. Additionally, financial services company Deloitte advised that companies cannot afford to ignore adopting sustainability measures and smart-building technology. Deloitte’s 2015 Commercial Real Estate Outlook stated commercial real-estate owners will likely benefit from investing in the redevelopment or renovation of existing properties to enhance their ability to compete with new building stock.

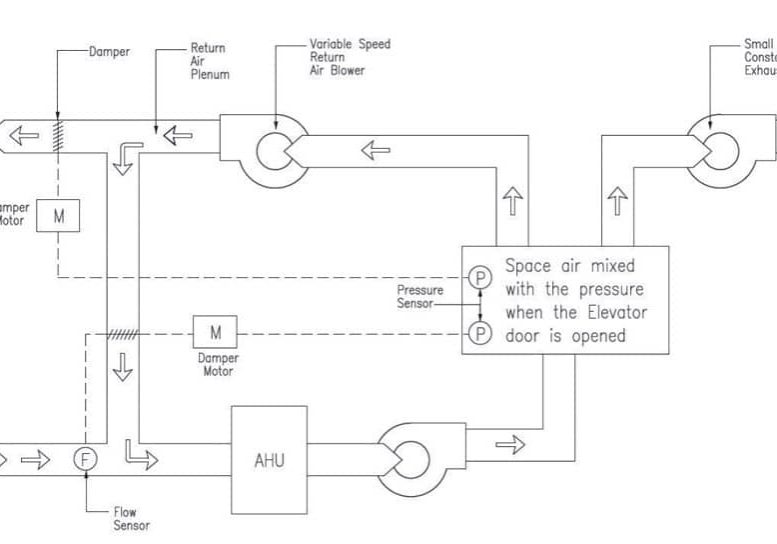

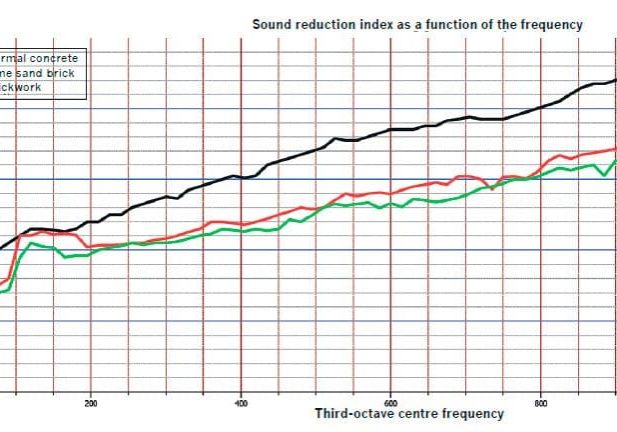

Elevators are vital to your building. If they are noisy, have jerky stops and starts or aren’t well ventilated, they will do nothing to attract new clients. Slow elevators frequently out of order can actually drive tenants away.

So, elevator company representatives should stress the importance of modernization to their commercial-property clients so their elevators will convey the high level of aesthetics and efficiency today’s tenants expect in a brand-new space. In addition to increasing property value, a modernization can also save operating expenses related to energy, improve traffic flow and make systems safer and code compliant.

Are Your Cabs a Blast from the Past?

A few seconds spent in an elevator cab with dated interior décor could give potential tenants a lasting impression. Cab upgrades can be negotiated in the price of a mechanical modernization, as well as handled by a company that solely offers new cab interiors. There are options that offer standard-finish interior panels designed with interlocking joints and clips that can be installed relatively easily. Or, you can choose to use conventional methods and customize a specific look. Note that the weight capacity of your elevator may limit the kind of materials you use. Flooring options, such as tile, may be too heavy for traction elevators.

Give Elevator Riders the “Right Touch”

Touchscreens can be used as an interactive elevator display to communicate with passengers. They can simply serve as an alternative car-operating panel or be customized to serve as a tool for marketing and communications. They can be programmed to feature content such as weather and news updates, or used to promote products and services. Glass surfaces are easier to clean than mechanical push buttons and help promote a sterile environment.

Shorten the Wait

Destination-control software improves traffic flow and reduces wait times by grouping elevators by the floor to which passengers intend to travel. This practice can increase handling capacity by up to 30%. A touchscreen directs passengers to their designated elevators by grouping all passengers traveling to the same floor in the same cab, thus reducing the number of stops the elevator makes.

Shift Gears

If you have an older traction elevator with a geared machine, you can improve ride quality and reliability, as well as lower energy costs and reduce power consumption by upgrading to a gearless machine. In most cases, the elevator’s major components are replaced with new microprocessor controls that have advanced dispatching, an efficient AC drive system and compact construction. This type of full-scale modernization is a costly investment, so employ industry experts who can customize a plan that works best for your building and its tenants. Expect savings of 25% more than the industry average for every kilowatt used.

Change the Oil

If your building has hydraulic elevators, you can save energy and improve performance just by changing the oil. Consider making the switch from petroleum-based hydraulic fluid to a vegetable-based hydraulic fluid. The easy and clean process takes only a few hours. Elevator technicians pump out the existing oil from your unit with a specially designed evacuation pump that is very efficient and can pump out more than 95% of existing oil in deep jack systems. The vegetable-based oils also may eliminate the need for temperature-control devices typically used to prevent oil from thickening. Now, building owners can save money by eliminating these devices that waste energy due to the fact that they cycle on even when the elevator is not in operation.

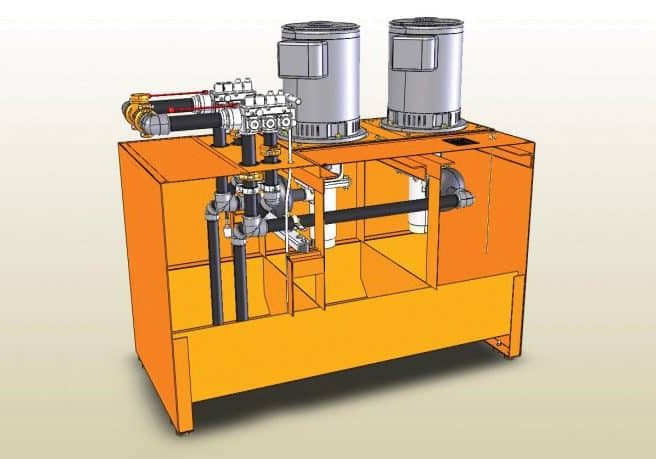

Replace the Pump

Hydraulic elevators have pump units, and normal wear and tear means seals can begin to leak or valves might not seal tightly, which causes system pressure to decrease over time. Decreased pressure requires the unit to unnecessarily power up to relevel, even in off-peak hours. Constant leveling throughout a unit’s downtime means unnecessary use of electricity and more wear and tear on the seals and pump parts.

Feed the Grid

Elevators equipped with regenerative drives can feed energy generated by the elevator’s braking system back into the building. So, energy that traditionally would have burned off as heat in the machine room, which increases air-conditioning costs, can now help keep the lights on. Since the regenerative drive captures excess energy and reuses it, rather than releases it as heat, it also reduces the traditionally high costs of cooling the elevator machine room.

Small Solutions with Big Impact

If your budget won’t allow a full-scale modernization, don’t worry. It is possible to increase efficiency without incurring large expenses. Lighting is a great place to shave off electricity consumption. Consider replacing your existing fluorescent tube lamps, incandescents or halogens with LEDs or other high-efficiency, low-heat lighting for a quick payback. LED push buttons are also available. Incorporate a solid-state starter that supplies the motor with a smooth and steady current, eliminating the large influx of current typically created by older mechanical starters. Such a system also uses less energy because the starters reduce spikes, which utility companies may bill at higher rates.

Get more of Elevator World. Sign up for our free e-newsletter.