Handi-Lift Equips Cesare Attolini

Jun 1, 2013

This New York City store gets a vertical-platform lift with a roller-chain hydraulic-drive system.

Cesare Attolini, an Italian suit designer, opened its first U.S. boutique in New York City in 2012. Located at 798 Madison Avenue, the store was equipped with an accessibility lift, which was completed in March 2012. Handi-Lift, Inc. worked with Shamut Design and Construction and Rosenberg-Kolb Architects to execute a challenging, yet aesthetically pleasing installation. INA Building Shop also worked on the project to provide glass and polished stainless-steel features.

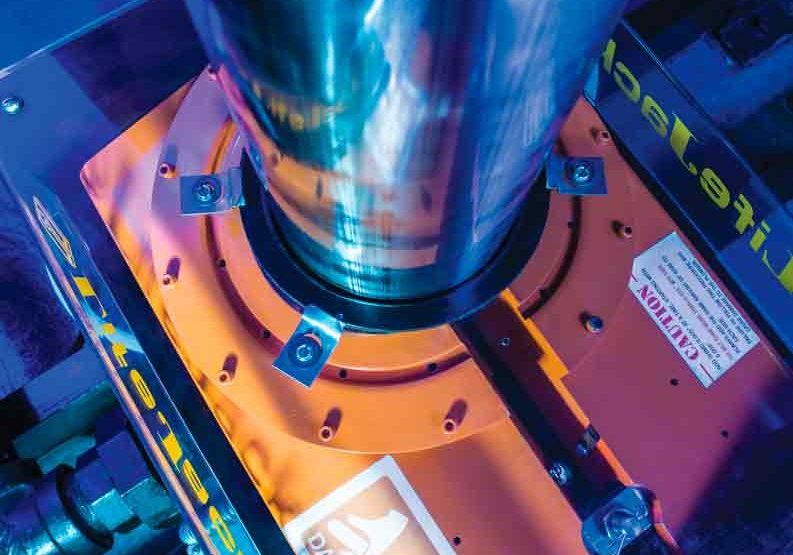

Garaventa installed its Genesis vertical-platform lift with a roller-chain hydraulic-drive system. A shoe was added on top of the drive mast so the glass could be extended to the ceiling on all four sides of the enclosure. The platform features a stainless-steel car-operating panel with bare-edged glass car sides. The pit floor is tiled, and the underside of the platform is covered with stainless-steel to maintain a “flawless” look when the lift is at the upper landing. The store’s black granite flooring provides contrast with the polished stainless-steel panels on the face of the mast.

When one steps into the lift at the upper landing, the sheer glass wall is the only thing separating the passenger from the chandelier, which is almost close enough to touch. The millwork trim around the entrances matches the adjacent cabinets, softening the impact of the glass and stainless-steel panels, creating a warm and inviting feel.

Handi-Lift used its Dorma BTS75 floor closers with 3/4-in. offset pivots, so the floor box would not protrude into the hoistway. The interlocks are Folger Adams 401R deadbolts wired into the lift to monitor the door closed and the bolt extended. This design eliminates additional hardware on the glass door as the lock is in the header, and the bolt protrudes into a hole in the patch hardware.

The hall stations are single button, and the lift is keyless for ease of operation. The disconnect and manual lowering device were hidden behind a panel in the adjacent cabinet to avoid exposing mechanical devices. ASME A18.1 required signage stating “no freight” and “capacity 500 pounds,” but this was not integrated into the hall station. Eventually, the universal-access symbol and the required language will be etched into polished stainless-steel plates to complete the look. Even the accessories match Cesare Attolini’s overall style.

Handi-Lift reduced the live load from 750 lb. to 500 lb. to compensate for the added weight on the platform, so it would not be overloaded or exceed safety factors. The glass is 5/8-in. thick, and the largest pieces are more than 10 ft. long. In order to support the upper sections of glass, a steel tube was extended in line with the header around the side of the enclosure between the enclosure and the stair, and a frame was installed in the ceiling behind the finishes to receive and stabilize the glass. Covering the face of the mast with polished stainless panels was challenging due to the slots required in the face for the sling arms to protrude to support the lift. This means the center panel (which has to be removable for service) floats: it is anchored in a slot at the bottom and pinned only at the top. The fascia wall under the upper gate was originally to be covered in polished stainless, but the architect decided to change it to a painted panel to match the walls in order to avoid a bright, reflective surface facing the lower landing.

Get more of Elevator World. Sign up for our free e-newsletter.