How to Choose the Correct Brake

Jan 1, 2011

This article discusses how a well-founded selection of reliable products can be made in spite of the competitive market, and explains what to take into account in order to avoid unpleasant surprises.

by John Eberle

The global effects of competition in the elevator industry have repeatedly caused the price to play a major role, even for safety-relevant components. The price/performance ratio for these products is very similar internationally. Therefore, performance and reliability are frequently economized on low-price products. Taking safety brakes as an example, this article shows you how a well-founded selection of reliable products can be made in spite of the intense competitive market, and explains what to take into account in order to avoid unpleasant surprises. The suggestions and recommendations are, of course, also applicable to other safety components.

The globalization of the elevator-drive market, the competitiveness (in particular in China) as the main market for elevators, and the resulting problems of reproduction or production in countries with low production costs have caused an enormous amount of competitive pressure, even with safety elements. Years ago, a clear commitment to reliability and the best quality could be observed. Nowadays, when talking to market participants, it becomes more obvious that price is top priority.

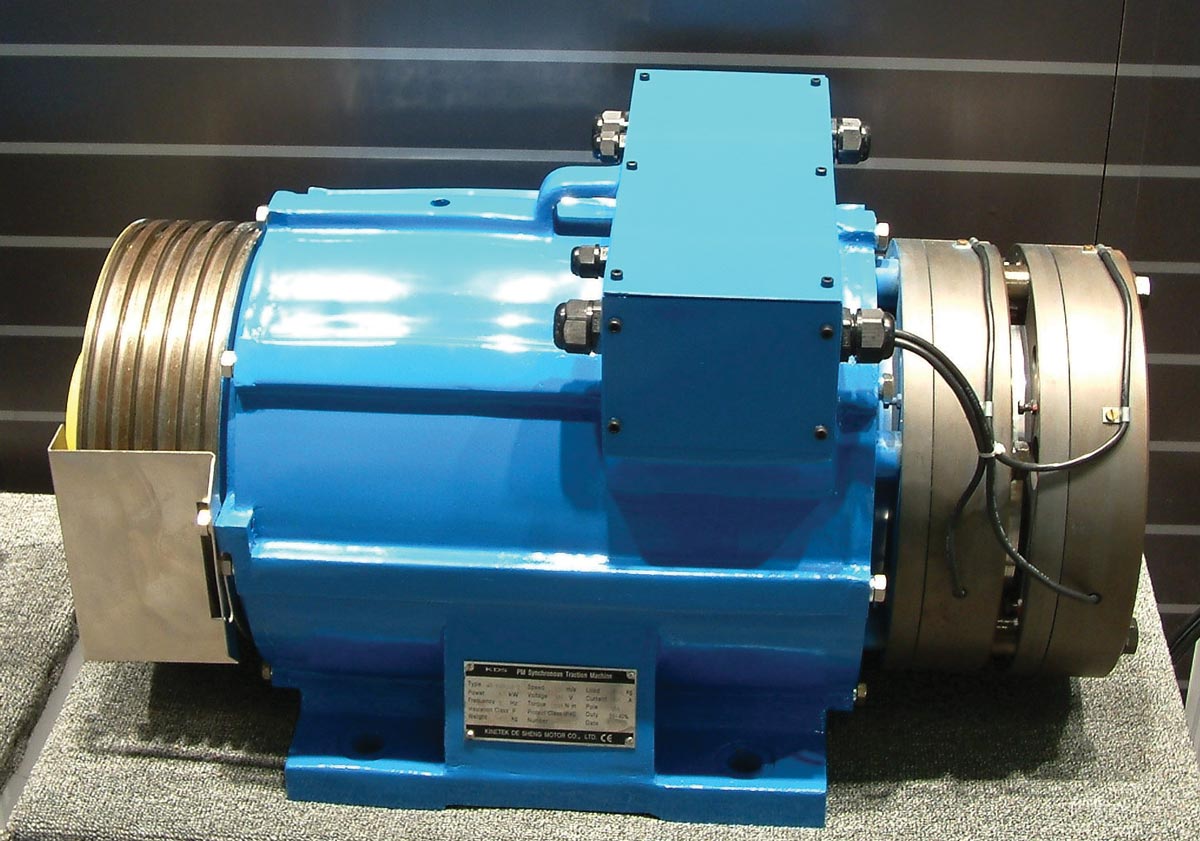

Normally, the leading global elevator manufacturers have the possibility to compile detailed requirement specifications based on product knowledge and market experience. The required components (for example, the safety brakes) can be adapted to the application quickly and evaluated through tests. However, this is not applicable for the supplier industry in its entirety. For example, motor manufacturers that do not obtain the corresponding feedback via field data and who do not have the necessary resources to employ a big engineering team normally work with simpler means to specify and test a brake. The majority of elevator components are launched on the market by medium-sized companies. The accident and malfunction statistics, with regard to passenger lifts, confirm that technically high-quality products are used and have been tested beforehand.

Passenger elevators are one of the safest means of transportation. Nevertheless, each accident and each breakdown should be considered a strong motivation for further improvement. Up to now, only a few experienced elevator brake manufacturers have been active on the market. Quality and reliability were guaranteed due to the respective competence. However, the rapid development (particularly in the Chinese market), creates a potential for danger. The situation has changed fundamentally because of young inexperienced market participants. Which criteria can a manufacturer of elevator motors, especially in the field of gearless technology, apply in order to choose a reliable brake?

To begin with, the possible supplier should be considered thoroughly, just as in general purchasing. A company does not only qualify itself by being able to manufacture brakes; knowledge and experience of brakes for elevator drives is important. Furthermore, the company has to have had a large selection of brakes on the market over a number of years. Only then is it capable of knowing the risks and is able to provide reliable products. Responsible handling of safety-relevant components, of course, also means a quality system, a rigorous quality control, an unambiguous traceability of the parts and further requirements for a modern quality business.

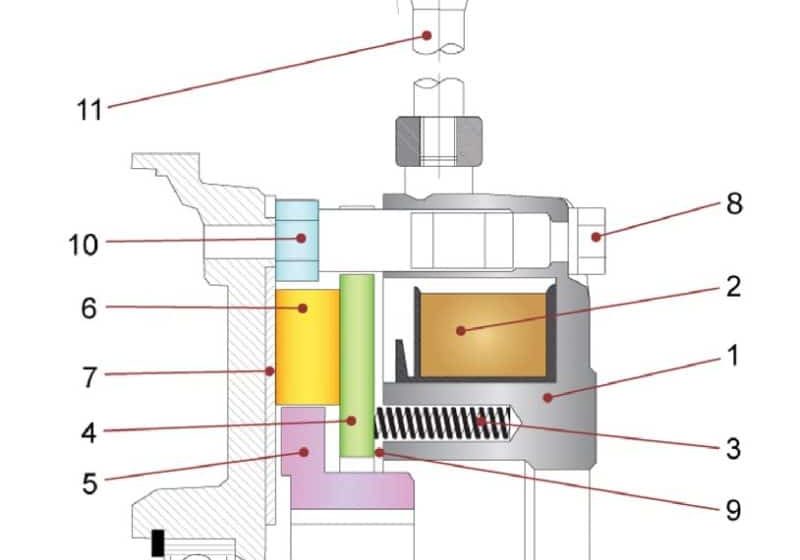

For 10 years, mayr has been developing and producing elevator brakes that have demonstrated their value on the market. With the market launch of the product series ROBA-stop®-silenzio®, ROBA®-sheavestop®, ROBA-stop® -Z, ROBA®-diskstop®, ROBA®-duplostop® and other application-optimised brake solutions, the company has installed completely new elevator brakes that meet the requirements of all existing and modern drive concepts.

During its work with non-European customers, mayr realized that very often these quality criteria are not demanded and that application-relevant certifications (which are essential in Europe) are not always required in other countries. The purchasing agents obviously often rely on the supplier adhering to the motto, “He knows what he is doing.” One could assume that a correctly installed system which operated, according to the instructions and corresponding to all safety guidelines is operationally safe.

For customers who install safety-relevant components especially in markets in which the quality philosophy is less established (and quality systems even less so), it is necessary to find a reliable partner. The customer’s goals should be to pursue development with regard to quality improvements and produce their own regulations and procedures in order to guarantee the continuous quality and reliability of the products.

The cooperation with global elevator manufacturers has shown that those large-scale enterprises go to considerable lengths to specify the requirements for safety-relevant components accurately and adjust them in elaborate testing procedures. Furthermore, due to practical day-in, day-out field experiences; these enterprises have a corresponding market input that makes it easier to consistently add detail to and work on the products or product requirements, and absorb critical points into the qualification process.

Smaller elevator companies or drive manufacturers who integrate safety brakes do not always have this direct feedback channel from the market. Smaller elevator manufacturers also do not have the same scope and often only have regional application areas in which certain problems may not occur very often. This means that if such a drive manufacturer needs reliable brakes, it will orientate itself on points with which they are familiar. However, in the course of business development into other markets, they might well be confronted with different conditions that bring new problems. In order to illustrate such problems, only two examples meant to represent many aspects are mentioned here.

On compact direct drives which, for example, in elevators in hot regions under glass roofs, are subject to high external temperatures, the maximum operational brake temperatures can reach over 70°C. The increase in temperature causes the material to expand, which can have fatal consequences. If, for example, a microswitch stops functioning correctly due to heat convection, service operation might become necessary. The costs for such an operation (especially if the machine is installed in foreign markets), can become expensive. The assumed cost reduction achieved by selecting a cheaper product is quickly lost, as the additional expenditure for service operations rapidly exceeds the costs saved. However, this is only the lesser evil. If such occurrences also lead to liability cases, the consequences are considerably more serious.

In addition to the costs, there are safety problems, which, if severe enough, can threaten the existence of the system manufacturer. Not long ago, an accident in Japan and the related media coverage caused considerable damage for the affected company’s image. This made it clear to the entire branch how a single event can drastically affect a company overnight. This shows how important it is to rule out safety risks at all costs by applying reliable components.

When selecting a brake supplier, the evaluation of the company in regard to quality and reliability is important, but, of course, the product specifications and their adjustment to the required criteria are of the utmost importance. Here, it is especially important to ensure that the specified values are not only achieved in new condition, but also that the running behavior over the entire service life are also taken into consideration. Internal tests at mayr’s manufacture sites, together with renowned elevator manufacturers, have shown that the noise of brakes in operation can fundamentally deteriorate.

It is extremely important that the performance values achieved in new condition are maintained over longer operating periods. If an elevator machine is located close to living space, distracting noises can cause complaints and follow-up costs. The people concerned will hardly accept the elevator becoming considerably louder after a relatively short operating period, when the agreeable noise behavior of the new condition is lost. For example, safety brakes with simple elastomer damping can be mounted so that they achieve acceptable noise values in new condition. However, these values do not stay constant over an adequate service life. On standard market brakes, a substantial increase in noise value can occur after only 100,000 switching actions. This service life is utterly unacceptable in the field of elevator technology.

Among other things, it is not common knowledge that temperature influences damping and noise behavior. If the brake is energized over a long period of time, an operating temperature of approximately 60°C is produced. This causes the rubber elements used for noise damping to expand, which improves the noise. Therefore, a brake at operating temperature does not cause problems during noise measurement. During product presentations, it’s easier to present the brake noise as being considerably better than it will probably be in reality.

However, in the long run, such solutions will satisfy only a few customers. The experiences mentioned above have obviously already prevailed even in new markets such as China, so that some Chinese drive manufacturers have also begun to rely on quality products. Unfortunately, it cannot be ruled out that in addition to the certified quality products, reproductions that do not offer the necessary reliability are also used.

Therefore, it is necessary to specify appropriate brakes and make sure that these are actually used – for example, by checking the type tag. This ensures that the most important components offer the expected reliability. For more than 100 years, mayr has been vouching for quality. c

Get more of Elevator World. Sign up for our free e-newsletter.