How the Use of Machine Data Can Help Consolidate Elevator Maintenance Across National Boundaries and Different Codes

Aug 1, 2025

This paper was presented at the 2024 International Elevator & Escalator Symposium in Paradise Island, Bahamas.

by Patrick Bass and Daan Smans

1. Abstract

Currently, more than half of the world’s population lives in urban areas (55%, up from 30% in 1950).[1] Meanwhile, projections indicate that future population growth can be accounted for almost entirely by a growing number of city dwellers.[2] To facilitate this growth, cities are increasingly growing upward, as rapid outward expansion often causes distorted land markets, deficient services in growing areas and disjointed informal expansion.[3]

Subsequently, elevators play an increasingly important role in our everyday lives. Elevators enable smooth people flow at home, work and retail spaces alike — until they go out of service. To ensure safe and reliable operation of elevators, adequate maintenance in compliance with local code is required.

Companies specialized in elevator maintenance typically follow Maintenance Control Plans (MCPs). These are essentially documented sets of maintenance tasks, procedures, examinations, tests and records that ensure that equipment is maintained in compliance with applicable requirements.[4]

Emerging technologies such as machine data obtained through sensor fusion, machine learning and the Internet of Things (IoT) are now enabling dynamic MCPs tailored to the needs of individual elevators regardless of make, model, age or geography. Essentially, by acquiring machine data directly at the sensor edge, the operating parameters of the elevator are interpreted through the universal laws of physics.[5]

For example, the operation of an elevator door can be monitored through fusing optical sensors (e.g., opening and closing distance), accelerometers (e.g., vibrations and velocity), temperature sensors (e.g., door motor temperature) and so forth.

When applying machine learning to the vast amounts of data collected over time, the aggregated picture provides an assessment of the elevator’s actual maintenance needs. The underlying IoT-based infrastructure enables connectivity at scale anywhere there is internet connectivity. Lastly, local requirements can be factored into the data model as geography-dependent criteria, ensuring compliance.

2. Introduction

When thinking of mass transportation systems, many of us first think of buses, subway trains, etc. This is unsurprising; Merriam Webster defines mass transit as “the transportation of large numbers of people by means of buses, subway trains, etc., especially within urban areas.[6] However, one form of mass transit not explicitly listed in Merriam-Webster — but fully fitting the criteria otherwise — stands out above the rest in sheer ridership: the elevator. For example, Americans make more than 20 billion trips per year by elevator[7] — twice the number of trips made by what people typically think of as mass transit.[8]

Pushed by an ever-growing global population that increasingly calls cities home, the megatrend of urbanization[1,2] will inevitably only push elevator ridership further and further. As elevators are electro-mechanical equipment, adequate maintenance becomes increasingly important, too. Various industry specific codes and standards, as well as the original equipment manufacturers, set minimum requirements for various types of maintenance. Elevator maintenance providers translate these into so-called MCPs to ensure maintenance is performed consistently across the installed base.

For a long time, this approach to elevator maintenance has proven its value. However, several key challenges are pushing the limitations of conventional elevator maintenance. Most crucially, the growing installed base needs to be maintained by an ever-decreasing pool of skilled elevator technicians. This challenge is further compounded by geographically varying codes and standards, the required on-hand knowledge of which increases the entry barrier and limits job mobility.

Fortunately, these challenges can be increasingly addressed through the emergence of thirdgeneration remote-monitoring technologies based on the concept of sensor fusion. This paper will elaborate on how the use of such machine data can help consolidate elevator maintenance across national boundaries and different codes by covering the following areas:

♦ The history and concepts of elevator maintenance (foundational)

♦ Key challenges impacting conventional elevator maintenance (relevant context)

♦ Letting elevators tell us what maintenance is needed when (practical application)

3. The History and Concepts of Elevator Maintenance

Before the industrial revolution, anything even remotely comparable to what we regard as equipment maintenance nowadays was scarce. One notable exception was the paper mills owned and operated by the French Montgolfier family. Around the year 1800, they started to employ regular maintenance, allocating 35 days of maintenance per year.[9] The rapid mechanization of our world during the industrial revolution demonstrated what the Montgolfiers had already realized: the need for increased preventive maintenance.

The modern elevator as we know it today is also a product of the industrial revolution. Although hoists in various forms had been around since antiquity, their designs were inherently unsafe. In 1853, Elisha Graves Otis debuted his invention of the safety brake at New York’s Crystal Palace Exhibition. In a public demonstration, he hoisted himself on a platform high above a crowd, then cut the suspension rope with an ax. “All safe!” he proclaimed as his safety device halted the fall.[10] In 1857, the first passenger elevator (steam-powered) was installed at the Haughwout Department Store in NYC.

Originally, elevator maintenance was simple: When it broke, you fixed it. Maintenance was purely reactive; this is typically referred to as corrective maintenance. However, without periodic inspections, equipment degradation through wear and tear goes by unnoticed, leading to frequent breakdowns. Although this may seem self-explanatory to us in this day and age, the missed opportunity to anticipate the benefits of regular preventive maintenance led to renewedskepsis about the safety of elevators and a subsequent reluctance to adopt them at scale in our everyday lives.

On the other side of the world, what was then The Kingdom of Prussia — currently modern-day Germany — this skepsis gave rise to the first-ever safety regulation for elevators in 1884 under the name “die Einrichtung und den Betrieb von Aufzügen.[11] A few years earlier, during the 1880 Mannheim Pfalzgau Trade & Agricultural Exhibition, Werner von Siemens demonstrated the firstever electric-powered elevator — interestingly as a byproduct of railroad design.[12] Back in the U.S., in 1887 Alexander Miles designed an elevator that would open and close its cabin doors and landing doors automatically when arriving or departing from a given floor.[13]

It was around this time that the adoption of passenger elevators really took off. Elevator designs started to become more convenient and user friendly, whereas elevator safety and reliability concerns were increasingly being addressed through periodic inspections. However, preventive maintenance on a regular basis was not yet codified. In the U.S., code writing for elevators initially fell to the Elevator Manufacturers Association but later shifted to the American Society of Mechanical Engineers (ASME).[14] In 1921, ASME issued the A17 Code of Safety Standards for the Construction, Operation and Maintenance of Elevators, Dumbwaiters, and Escalators[15] — the first-ever safety code for elevators with a dedicated section for preventive maintenance.

Since its introduction, years of experience have expanded this section. Both customary maintenance methods, new maintenance methods, as well as changes in technology, had to be considered. As maintenance items became more numerous in the code, they converged into a maintenance program. The present language specifies an MCP, and is both performanceand prescriptive-based.[16]

These MCPs had to be adopted by companies specialized in elevator maintenance and practically applied in their preventive-maintenance operations. Essentially, preventive maintenance is a process of routine examination, lubrication, cleaning and adjustment of parts, components and subsystems for the purpose of ensuring that the elevator’s performance complies with applicable code requirements. MCPs steer this by prescribing the necessary work items to be performed, providing a place to record the completed work and containing the records of completion.

Even though the emphasis has shifted from reactive to preventive maintenance due to the nature of electromechanical equipment, elevator breakdowns remain unavoidable. Even with regular elevator maintenance, the commonly accepted number of elevator breakdowns is up to four per year.[17] Therefore, elevator maintenance operations conventionally comprise both preventive and reactive maintenance:

- Preventive maintenance seeks to address equipment degradation caused by wear and tear through normal use on a regular basis. Wear and tear typically results in damage whereby the system is no longer operating in its ideal condition but can still function satisfactorily;[18]

- Corrective maintenance seeks to address equipment breakdowns whereby wear and tear has led to a fault in which the system can no longer operate satisfactorily (a change that produces an unacceptable reduction in quality). [18] Another cause of equipment breakdowns can be wrong use by the riding public (both unintended/accidental, as well as intended/vandalism).

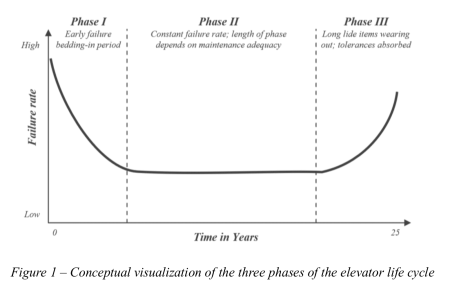

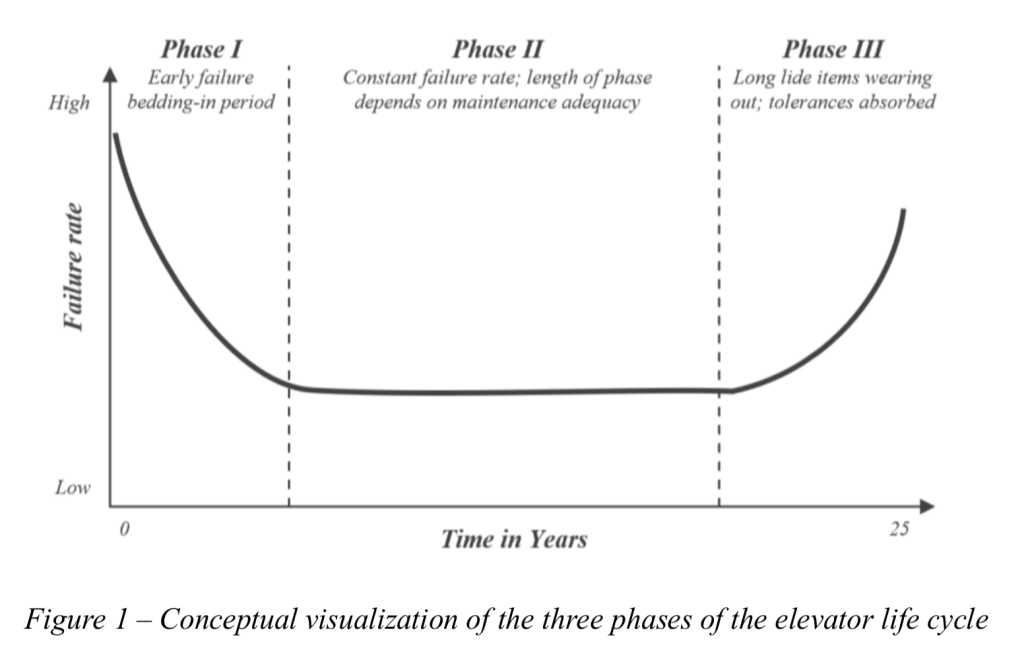

While many things can impact an elevator’s lifespan, a general guideline to follow is that elevators 20 years and older are likely candidates for modernization. Once an elevator is20-25 years old, it will generally be reaching the end of its cost-effective life. After this time, more frequent maintenance will likely be needed for equipment upkeep. But even so, overall reliability will decline. Figure 1 conceptually visualizes the phases of equipment life.

4. Key Challenges Impacting Conventional Elevator Maintenance

Although elevator maintenance operations are often compared to firefighting by industry professionals, many of the perceived daily challenges can be traced back to more fundamental underlying root causes. This section will explore two such root causes, one being a general crossindustry megatrend that, however, has a very industry-specific impact, and another topic that is purely an industry-specific issue.

The general cross-industry megatrend refers to the evercontinuing growth of the elevator industry driven by urbanization.[1,2] Although an ever-growing market is a good challenge to have, the expanding installed base needs to be maintained by an ever-decreasing pool of skilled elevator technicians. This causes a steady increase in units under maintenance per elevator technician, which, in turn, necessitates reducing the time spent per maintenance visit for the total workload to remain manageable. The increasing conflict between the ability to provide the desired quality of service while keeping the overall workload manageable presents a dilemma for daily elevator maintenance operations.

According to the U.S. Bureau of Labor Statistics, the employment of elevator installers and repairers is projected to grow 6% from 2023 to 2033 — faster than the average for all occupations.[19] Although the aging population already reduces the pool of available workers in general, the rapid rise of the internet and the industries that formed around it are creating new jobs that did not exist before. Thus, as the workforce ages and more jobs are being created, the reduced access to skilled labor is widely anticipated to persist over the next few decades. Although statistics vary country to country, the same trend is generally recognized in other elevator markets where upkeep of the existing installed base comprises the majority share of the total elevator business.

The more industry-specific issue is the stalled effort to harmonize codes and standards. Essentially, localization of codes increases complexity, reduces economies of scale and imposes barriers on worker mobility. Although the benefits of harmonization are generally subscribed to within the industry, convergence also necessitates making compromises. This effort is channeled through the International Standards Organization (ISO) Committee TC 178, which comprises experts from national committees.

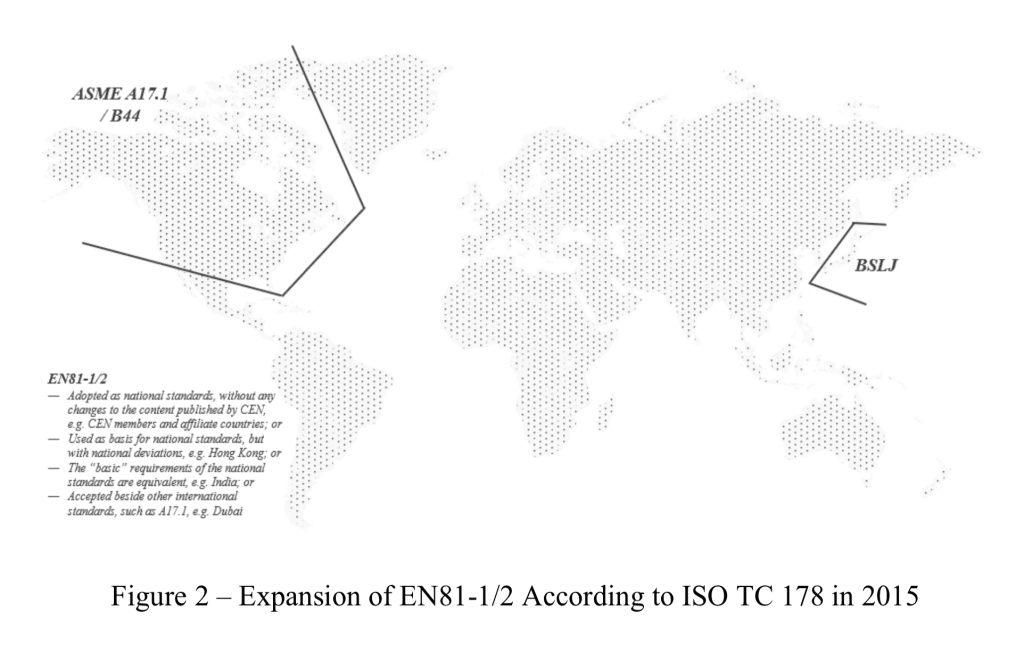

Over the past 30 years, there has been a clear trend toward convergence with the European Norm (EN) 81-1/2 (since 2014 revised to EN 81-20/50). However, longstanding codes in mature elevator service markets — such as the harmonized ASME A17.1/B44 code adopted in the U.S. and Canada (respectively the BSLJ in Japan) — continue to prove their value to this day. What is crucial to understand is that the underlying approaches between the EN 81 on the one hand and ASME A17.1/B44 (respectively the BSLJ) on the other are intrinsically different:

♦ EN 81 is a performance-based code, which uses certification documents.

♦ ASME A17.1/B44 and BSLJ are prescriptive codes that require code compliance.

Due to these different approaches to codification, declaring equivalence brings inherent risks. In 2015, the ISO TC 178 updated the convergence roadmap such that it skipped the years of work normally required to harmonize and instead adopted the performance-based European Norms into a new ISO 8100, Parts 1 and 2. This resulted in understandable concerns by various parties involved in technical committee work.

Since 2018, progress toward converging to one truly global elevator code has stalled. The adopted codes around the world show the only countries not aligning to EN 81-1/2 are the U.S., Canada and Japan, according to the ISO TC 178 in 2015.

Specific to the U.S., there also exists a significant degree of fragmentation within the country, as not all local Authorities Having Jurisdiction (AHJs) auto-adopt the latest version of the ASME A17.1/B44 code once released. The latest version of the code dates from 2022, whereas, for example, the AHJ looking after the largest elevator installed base in the U.S. — the State of California — still enforces the 2003 version. Additionally, there are numerous local ordinances that are different between AHJs. This poses a barrier to worker mobility — both those entering the trade new, as well as existing professionals who would like to switch companies — even on a local level, as several larger metropolitan areas stretch across different AHJs.

5. Letting Elevators Tell Us What Maintenance Is Needed When

Many of the world’s leading elevator companies developed and introduced their first versions of remote monitoring systems (RMS) starting in the late 1980s and throughout the 1990s. These first-generation systems were based predominantly on pre-processed diagnostical data from the elevator control system, using rudimentary analytics and few sensors. These systems were developed before the advent of the internet, thus typically storing the data on local databases.

Since 2018, progress toward converging to one truly global elevator code has stalled. The adopted codes around the world show the only countries not aligning to EN 81-1/2 are the U.S., Canada and Japan, according to the ISO TC 178 in 2015.

These first-generation systems brought innovation to the elevator industry, making it an early adopter of remote monitoring technology. However, limitations in technology also meant that these original systems came with little workflow integration and, as such, inconsistent materialization of the benefits, at best. The rapid rise and widespread adoption of the internet that started in the 1990s gave rise to the next generation of remote monitoring technology based on the Internet of Things (IoT).

The term “Internet of Things” was first coined by British technology pioneer Kevin Ashton back in 1999.[20] Essentially, IoT refers to a network of physical items or “things” — within the context of this paper, “things” being elevators — that are embedded with sensors, software and other technologies with the purpose of connecting and sharing data with other devices and systems over the internet.

Essentially, IoT provided an infrastructure backbone that solved many of the prior technology limitations. For instance, cloud technology provided accessibility from anywhere with any device, centralized data security, higher performance and availability, quick application development and unlimited storage capacity. Within the cloud, Machine Learning (ML) technologies made it possible to process and adapt to vast amounts of data; by using statistical algorithms, ML could learn from data, generalize unseen data, and in so doing perform tasks without explicit instructions from humans. RMS that leverage an IoT infrastructure backbone are typically referred to as second-generation RMS.

However, the approach in terms of what type of input data would be used was not reassessed. The elevator controller being the proverbial “brain and central nervous system” of the elevator was generally deemed as the most logical source of providing all the relevant data needed. The general underlying assumption was that elevator technicians already made extensive use of the elevator controller’s diagnostic capabilities as the prime source of truth. The emphasis at the time was to harmonize workflows and centralize diagnostic toolsets. This meant that pre-processed diagnostical data from the elevator control systems continued to remain prevalent.

Elevator controller-centric IoT solutions soon proved to introduce their own constraints in terms of compatibility across different makes, models and generations of elevator equipment, as well as limitations with data quality and usability.

Compatibility limitations were the result of the wide variety of different hardware connectors used for interfacing with the elevator controller — respectively, how the software of the IoT edge device interacted with the elevator controller. Many older generation elevator controllers also did not provide the ability to interface at all and would first require modernization. From a data perspective, in order to model failure detection, ML needs to be able to ascertain how an elevator functions within normal operating parameters, how these change in the lead-up to a breakdown and, finally, what the breakdown actually looks like. The elevator controller only provides error codes and status mode changes when an issue arises, thus drastically limiting ML’s predictive capabilities.

Around the turn of the current decade, the first IoT solutions using data directly from the sensor edge started to emerge in the industry. This is the time when the concept of sensor fusion came into play. Unlike previous generations — which take pre-processed diagnostical data from the elevator controller — sensor fusion takes its data directly at the source from multiple different sensors working in parallel. This way, the universal laws of physics can be applied. Although IoT is still being used as backbone infrastructure, the approach in terms of data acquisition is so different that solutions based on sensor fusion are typically being referred to as the third generation of RMS. Another key difference is that, this time, either elevator companies specialized in sensor technology or tech start-ups were the first movers. This has since enabled access to RMS-type technologies to a wider group of elevator maintenance providers.

When properly synthesized, sensor fusion helps to reduce uncertainty in machine perception as each individual sensor comes with its own unique pros and cons. Using just one sensor to identify the surrounding environment is not sufficiently reliable, translating into errors in the produced outcome. Conversely, sensor fusion algorithms process all inputs and subsequently produce outcomes with higher accuracy and reliability — even when individual measurements are not always sufficiently reliable. The concept of sensor fusion thus resolves the limitations inherent to using the elevator controller’s diagnostic data, i.e., error codes and status mode changes. Sensors can be applied universally irrespective of make, model or equipment age. Moreover, by using data directly taken from the sensor edge, data quality and usability limitations are negated by the ability to use the universal laws of physics.

Universality in terms of access to the technology, as well as consistency in the data acquisition, now enable widespread adoption of dynamic MCPs. Although MCPs did not originally consider remote monitoring capabilities, they neither directly nor indirectly prohibit the use of actionable insights provided by such systems. By factoring in the situational specifics of each and every individual elevator, potentially significant optimization of time spent on-site can be achieved without compromising the quality of service provided.

Moreover, the IoT infrastructure backbone also provides the means to factor in any specific code requirements and local ordinances on a per-AHJ level. This way, compliance with applicable maintenance requirements can be ensured without the need for extensive training. This reduces the worker mobility barrier.

Conclusions

Pushed by an ever-growing global population that increasingly calls cities their home, the megatrend of urbanization[1,2] will inevitably push elevator ridership only further and further. As elevators are electro-mechanical equipment, adequate maintenance becomes increasingly

important, too.

However, the expanding installed base needs to be maintained by an ever-decreasing pool of skilled elevator technicians. The ability to provide the desired quality of service while keeping the overall workload manageable presents a dilemma for daily elevator maintenance operations. This is further compounded by reduced worker mobility due to a fragmented landscape in terms of elevator code harmonization and version adoption. These challenges put conventional approaches to elevator maintenance increasingly under pressure.

Emerging technologies recently gave rise to the third generation of RMS based on the concept of sensor fusion. Unlike previous generations — which take pre-processed diagnostical data from the elevator controller — sensor fusion takes its data directly at the source from multiple different sensors working in parallel, applying the universal laws of physics for data analysis. This way, every elevator irrespective of make, model or age can be outfitted with an RMS.

By factoring in the specifics of each and every unique elevator, MCPs become dynamic based on the actual maintenance need. This way, machine data can help consolidate elevator maintenance across national boundaries and different codes.

References

[1] United Nations, Department of Economic and Social Affairs, Population Division (2019). World Urbanization Prospects: The 2018 Revision (ST/ESA/SER.A/420). NY, NY, USA: United Nations

[2] United Nations, Economic and Social Council, Commission on Population and Development (2018). World Demographic Trends (E/CN.9/2018/5). NY, NY, USA: United Nations

[3] Mahendra, A., and K.C. Seto. 2019. “Upward and Outward Growth: Managing Urban Expansion for More Equitable Cities in the Global South.” Working Paper. Washington, D.C., USA: World Resources Institute. Available online at citiesforall.org.

[4] Koshak, J.W., 2010. “Maintenance on New Equipment Designs: Application of the MCP to MRL Elevators,” Mobile, Alabama, USA: ELEVATOR WORLD.

[5] Wu, Y., Sicard, B., and Gadsden, S.A., 2024 “Physics-informed machine learning: A comprehensive review on applications in anomaly detection and condition monitoring.” McMaster University, Hamilton, Ontario, Canada: Elsevier

[6] Merriam Webster, dictionary for the English language. Springfield, Massachusetts, USA: Merriam-Webster, Inc. Accessed online September 3, 2024, at merriam-webster.com/dictionary/ mass %20transit.

[7] National Elevator Industry, Inc, 2020 “Elevator and Escalator Factsheet,” Topeka, Kansas, USA: NEII.

[8] American Public Transportation System, “Public Transportation Facts,” Washington, D.C., USA: APTA. Accessed online September 3, 2024 at apta.com/news-publications/public-transportationfacts.

[9] Rosenbrand, L.N., 1985 “Productivity and Labor Discipline in the Montgolfier Paper Mill, 1780–1805,” The Journal of Economic History, Cambridge, U.K.: Cambridge University Press.

[10] Public Broadcasting Service, “Who Made America – Elisha Otis,” Arlington, Virginia, USA: PBS. Accessed online September 4, 2024 at pbs.org/wgbh/theymadeamerica/whomade/otis_hi.html.

[11] Rosin, O., 2021 “Kein Aufzug ohne Reglement: Eine kleine Geschichte der Aufzugsverordnungen,” Senkrechtstarter – das Online-Magazin zur vertikalen Mobilität, Berlin, Germany: Schindler Deutschland GmbH in cooperation with Raufeld Medien GmbH. Accessed online September 11, 2024, at magazin.schindler. de/technologie/eine-kleine-geschichte-deraufzugsverordnungen.

[12] Siemens, “Lift Me Up!,” Munich, Germany: Siemens AG. Accessed online September 11, 2024, at siemens.com/global/en/company/about/history/stories/electric-elevator.html.

[13] Kelechava, B., 2022 “A Brief History of Elevators,” American National Standards Institute, Washington, D.C., USA: ANSI. Accessed online September 11, 2024, at blog.ansi.org/history-ofelevators.

[14] Varasi, J., 2010 “Heavy Lifting: The History of the Elevator Code,” American Society of Mechanical Engineers, New York City, NY, USA: ASME. Accessed online September 11, 2024, at asme.org/topicsresources/content/heavy-lifting-the-history-of-the-elevator-code.

[15] American Society of Mechanical Engineers, 1921, “A Code of Safety Standards for the Construction, Operation and Maintenance of Elevators, Dumbwaiters, and Escalators,” New York City, NY, USA: ASME.

[16] Koshak, J., 2010 “Continuing Education: Maintenance — Maintenance Control Program,” ELEVATOR WORLD, Mobile, Alabama, USA:

[17] Filippone, J., Feldman, J.D., Schloss, R.D., Cooper, D.A., Stabler, J.L., and Zambrano, J.F., 2019, “Elevator and Escalator Accident Reconstruction and Litigation, Fourth Edition”, Tucson, Arizona, USA: Lawyers & Judges Publishing Co.

[18] Worden, K., Dulieu-Barton, J.M., 2004, “An Overview of Intelligent Fault Detection in Systems and Structures,” Structural Health Monitoring, London, U.K.: SAGE Publications.

[19] U.S. Bureau of Labor Statistics, “Occupational Outlook Handbook – Elevator and Escalator Installers and Repairers,” Washington, D.C., USA: U.S. Bureau of Labor Statistics. Accessed online September 24, 2024, at bls.gov/ooh/construction-and-extraction/ elevator-installers-and repairers.htm.

[20] Bassi, A., Bauer, M., Fiedler, M., Kramp, T., Van Kranenburg, R.,Lange, S., Meissner, S., 2013, “Enabling Things to Talk — Designing IoT solutions with the IoT Architectural Reference Model,” Springer Open, Heidelberg, Germany: Springer.

Get more of Elevator World. Sign up for our free e-newsletter.