Hybrid Rope Development for Elevators

Jul 1, 2012

Gustav Wolf discusses its HyTrac™ rope and other hybrid rope characteristics.

The global trend of constructing taller buildings has created a demand for longer elevator ropes. As the weight of the rope increases, the load on elevators becomes greater and the breaking force of the ropes must rise. An increase in the breaking force is achieved through an increase of rope diameter. As rope diameter grows, the weight of the rope increases. Gustav Wolf has succeeded in developing an elevator rope that, when compared to traditional elevator ropes of the same diameter, achieves equal or greater breaking force with substantially reduced weight. The new rope, named HyTracTM, is a hybrid rope that combines high-strength synthetic fibers for the rope core, with steel wires composing the outer strands.

Ropes made from high-strength synthetic fibers are much lighter than steel-wire ropes. However, the properties of synthetic fibers substantially differ from steel wires in such areas as abrasion resistance, stretch and resistance to light. In addition to purely synthetic fiber ropes, hybrid ropes have existed for some time. These were, until now, predominantly used on drums for crane installations. The loading of a rope in a traction-sheave elevator differs from one on a drum. In elevator installations, ropes are subjected to strong bending stress, and in the traction sheave, associated lateral pressures occur.

Essential to the development of combining high-strength synthetic fiber rope core and steel-wire outer-strand is that the core must carry part of the load, which is also the case for steel-core rope. In an elevator rope with a traditional fiber core comprised of natural synthetic fiber, the core is not load carrying and only serves a support function. Should the core assume a load-bearing function, the stretch of the steel strands and the core must be correlated, so the core and outer strands carry an equal load.

Generally, high-strength synthetic fibers have higher elongation than steel wire. Therefore, a core construction with less elongation must be used. A further requirement was for the core to possess a stable, round structure that, after bending stress, maintains its form so the rope does not become deformed. A rope deformation could lead to a running disturbance in the groove and premature wear. As elevator ropes bend over sheaves, the strands move against the core. Friction develops on the core surface, which leads to abrasion. Since the abrasion resistance of high-strength synthetic fibers is small, it is necessary for the load-bearing fibers to have some type of protective covering.

The newly developed hybrid rope was tested extensively in Gustav Wolf’s laboratories for diameter tolerance, stability, breaking force and stretch. A substantial portion of testing also focused on researching rope behavior under the influence of bending. In addition, hybrid ropes ran on the fatigue bending test stand under normal elevator-rope test conditions.

Tests yielded the following results:

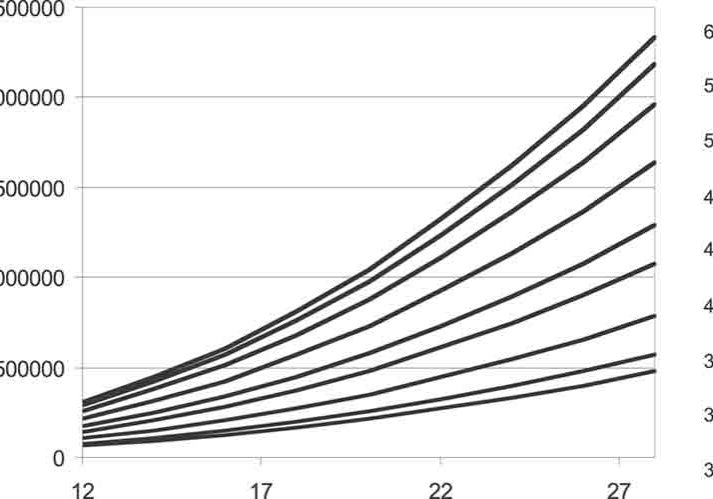

- In comparison to ropes with steel cores, breaking force is equal or up to 8% greater, weight is 20% less, and bending performance is up to 50% higher.

- In comparison to ropes with natural fiber cores, breaking force is approximately 50% higher.

- Total stretch is less than that of ropes with natural-fiber cores and somewhat higher than that of ropes with steel cores. Based on practical experience with normal break-in operation, the elastic stretch of the hybrid rope is consistent with the elastic stretch of a steel-core rope.

In all fatigue bending tests, the appearance of wire breaks was the primary cause of steel-strand failure, though the synthetic fiber core was not destroyed. Therefore, recognition of the need for rope replacement is possible based on the normal method of the number of wire breaks. In the hybrid rope, there is less pressure between the outer strands and core – the opposite of a steel-core rope. Additionally, no fretting arises at the contact points between the core and outer strands.

Hybrid rope advantages include:

- Substantial weight reduction at the same or higher breaking force of traditional steel rope.

- Unchanged traction in comparison to elevator rope made from steel wire, which current conventional drive sheaves permit.

- Greater durability against external damage in comparison to a purely high-strength synthetic fiber rope.

- Positive recognition of the replacement criteria on the basis of broken wire count.

With hybrid rope, an alternative has been found for elevator ropes used in high-rise installations, where the weight of the means of hoisting is reduced and greater heights can be surmounted.

Get more of Elevator World. Sign up for our free e-newsletter.