What to keep in mind when undergoing the right modernization solution

by Dr. K. Ferhat Celik

Modernization is necessary to bring elevators into compliance with new codes and regulations. The right modernization solution satisfies high performance, reliability, efficiency, superior ride quality and—most importantly—ecological aspects. As the carbon footprint of products increasingly becomes an important property, the ecologic suitability of elevators should be taken as one of the prime driving points in modernizations.

Building owners who invest in modernization are usually concerned about compliance with new code, ride quality and the cost of modernization. Whether partial component changes on existing elevators or complete replacement of them takes place, the elevators can be successfully brought up to date on codes and ride quality. However, the situation of their carbon footprints might be a very different story.

All competent elevator companies meet new standard requirements and can provide good ride quality. However, energy consumption and ecological aspects of the solutions offered may be very different. Nowadays, ecological assessment of elevator modernization is wrongly degraded to energy consumption only, omitting the fact that material and maintenance are two other major factors to be considered for a true ecological evaluation.

The investment on a regenerative inverter for low-usage elevators will never pay itself off during a human lifetime.

Modernization of hydraulic elevators should be evaluated much differently than that of traction elevators. This is because hydraulic elevators are used up to five floors, and more than 70% of them see infrequent usage. A low-usage elevator can be suitably modernized by using a conventional hydraulic elevator easily. Though its energy consumption during operation is higher than a technologically advanced hydraulic or traction elevator, the investment (and, in most cases, the total carbon footprint) of the conventional hydraulic elevator are much lower.

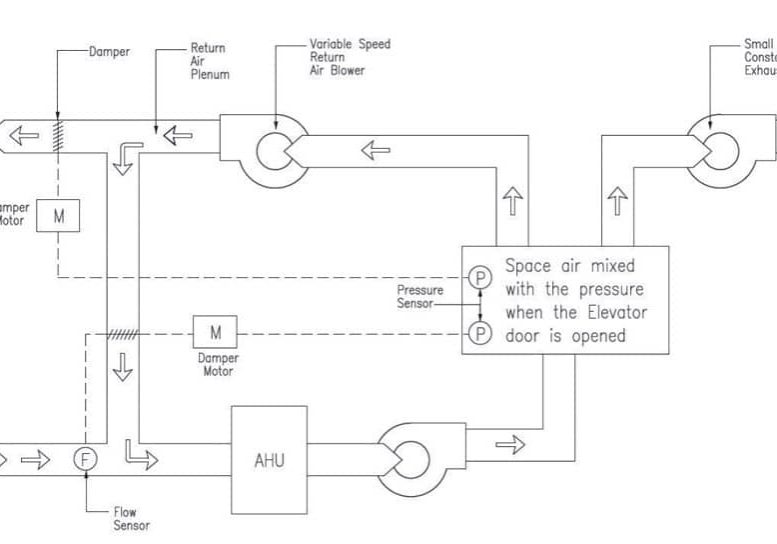

One of the most important components in modernization is the elevator controller. Energy consumption at standby can be reduced to a minimum with the current generation of elevator controllers. Since only the drive unit and safety systems of hydraulic elevator systems differ from traction elevators, this article will mainly consider modernization of the power unit and control valves, and try to correct the most common mistakes made in modernization of hydraulic elevators.

What to Modernize

An important step before initiating a modernization is to check the elevator technical data and conditions of the working environment to determine if the power unit, control-valve group and cylinder(s) are really suitable for the elevator. In this way, previously made design mistakes can be found and corrected. Change of usage of the elevator throughout the years, and results of application of new regulations may require modifications in elevator speed and/or capacity, which might require new components to be used—that is, an intensive study of the existing system is needed to determine what to renew and what to reuse. Replacing an existing elevator with a new one should be the last option, while this is both the most expensive and worst for the environment.

Modernization of the Power Unit

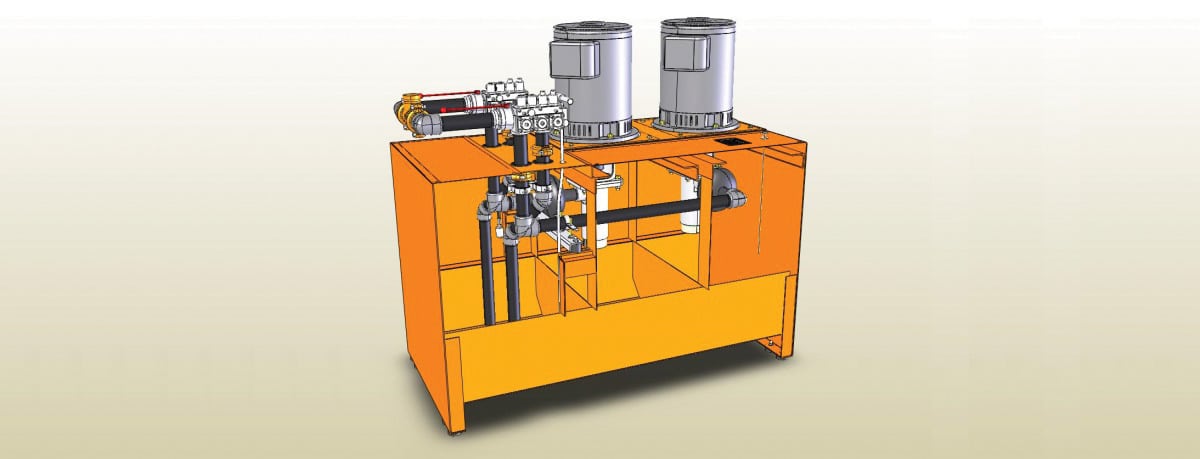

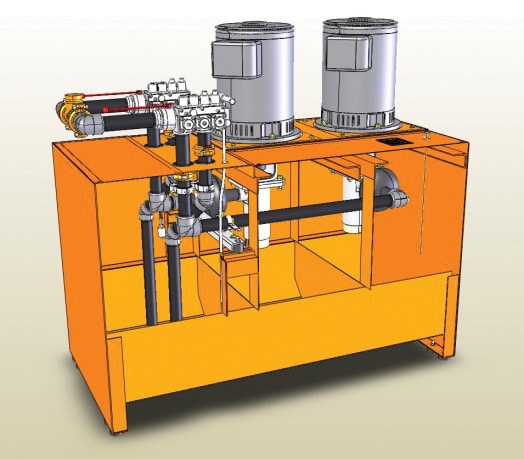

The power unit produces flow and determines the maximum speed of the ram. Empty cabin weight on the ram and payload of the elevator give the working pressure range. When the power unit is out of date and/or the speed of the elevator or lifting capacity is modified, the power unit may need to be renovated. Depending on the hydraulic drive technology used, the internal design, control valve, connections and size of the power unit might be redesigned in this process.

Modernization of the Cylinder

The hydraulic cylinder should not be changed unless necessary. Doing so will increase the modernization cost considerably, and the replacement of seals and drain pipes, and protecting against corrosion are usually sufficient during modernization. However, damaged or bent rams, or heavily corroded cylinders should be renovated or replaced. Another reason for cylinder replacement is the change of lifting capacity. As a rule of thumb, when elevator traffic analysis allows, decrease the lifting capacity of the elevator, instead of replacing the cylinder.

Using Advanced Technology

The use of inverters in hydraulic elevators has decreased energy consumption, allowed smaller motor sizes, eliminated high surge currents, reduced noise, cooled oil and provided good ride performance. The level of such advanced elevator technology in modernizations depends firstly on the usage of the elevator. Secondly, correct selection of the technology is vital to obtain cost-effective benefits: investing in the most advanced vertical-transportation technology on a low-usage elevator is normally not feasible. This is because of the fact that the inverter and its peripheral devices are costly and require energy to be active, even when the elevator is on standby.

No solution is attractive or ecological if it is not cost effective. Keeping this in mind, for example, a low-usage elevator in a two-to-three-floor house with fewer than 20 cycles per day normally requires the update of some components for it to comply with new codes. If necessary, the elevator controller can be modified or replaced to minimize standby energy consumption and surge current. (A quality mechanical valve is sufficient for such elevators, while the fluid temperature remains nearly constant). On the other hand, highly advanced technology solutions are suitable for high-usage elevators. Such advanced technologies as variable-voltage, variable-frequency (VVVF)-driven control valves offer low levels of energy consumption, better ride quality and faster investment payback.

Regenerative drives are much more costly and, therefore, can be feasible only for use in the most heavily used elevators. The investment on a regenerative inverter for low-usage elevators will never pay itself off during a human lifetime.

Elevator Market Needs for Modernization

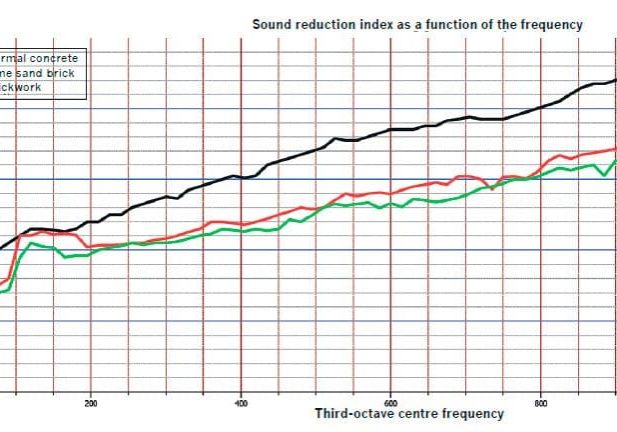

Though the general trend in the elevator industry is toward lifts with lower energy requirements, the use of hydraulic elevators with inverters (VVVF-driven control valves) has not found enough appeal yet. This is because of the fact that existing solutions are generally more demanding, costly and difficult to maintain. Instead, a transition solution with electronic control valves is most often used in modernizations. Electronic valves provide up to 30% energy savings, compared to 40–65% with VVVF-driven valves. On the other hand, high starting current, noise and oil-heating characteristics will be similar to those of mechanical valves.

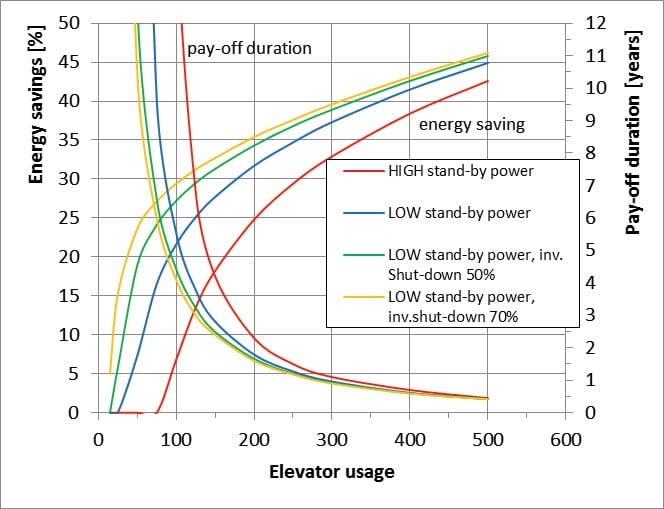

There are close correlations among energy savings, investment payoff duration and elevator usage (Figure 2). With increasing elevator usage, payoff duration decreases, and energy savings increase. Compact, simple-to-implement and inexpensive VVVF-driven advanced solutions are needed to establish an acceptable solution for the market. Since most hydraulic elevators are low usage, it is necessary that the solution is practical and affordable to be applicable for low-usage elevators.

Installation and maintenance properties are of prime importance to offer a cost-effective solution. Therefore, with a complex solution with many closed-loop systems nested into each other, using a motor encoder and special control board, would require expert technicians to install and maintain more system components. As a result, the system cost would increase, and pay-off duration would be much longer.

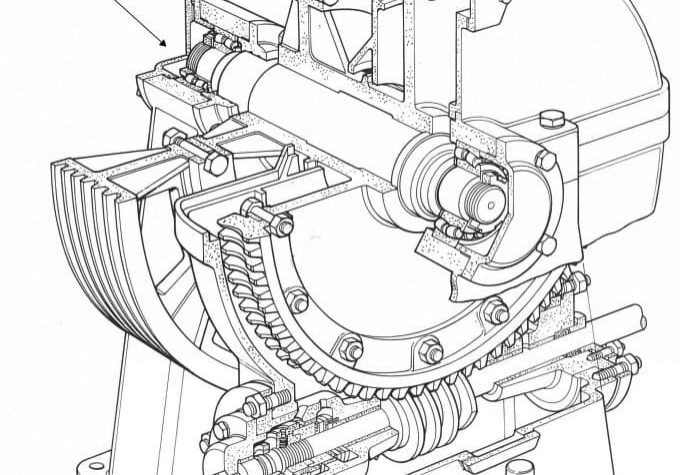

Solutions like the Blain Hydraulics EV4-vvvf (Figure 3) are compact, simple and inexpensive, intended to be applied to low-usage elevators with short payoff durations. These also serve as control valves for modernizations, because they allow existing power units to be reused. In the EV4-vvvf’s case, an existing Blain EV100 mechanical valve on a power unit can be converted to an EV4 valve by using only a renovation kit. This enables quick application of modernizations and shortens the payoff duration.

Many parts in a used elevator are not worn out and can be kept for many decades.

Circular Economy and Environmental Impact

The circular economy aims to rely on renewable energy, minimize tracks, and eliminate the use of toxic chemicals and get rid of waste through careful design. In the manufacturing industry, product materials and components are designed for reuse without producing waste. On the other side, global warming and environmental pollution concerns are the driving forces that persuade manufacturers to produce energy-efficient products. As a result, optimum utilization of natural resources has become an important issue in the elevator sector. Lifecycle assessment is the method by which to determine the environmental impact of products, such as the environmental performance of elevators.

When it comes to modernization, reuse of most existing hydraulic components becomes of prime importance for the user and environment. Many parts in a used elevator are not worn out and can be kept for many decades. Considering the fact that more than 2.5 million hydraulic elevators are running worldwide, reusing components instead of replacing them reduces the environmental impact and saves money. Changing all hydraulic components would increase modernization costs and will make a high carbon impact.

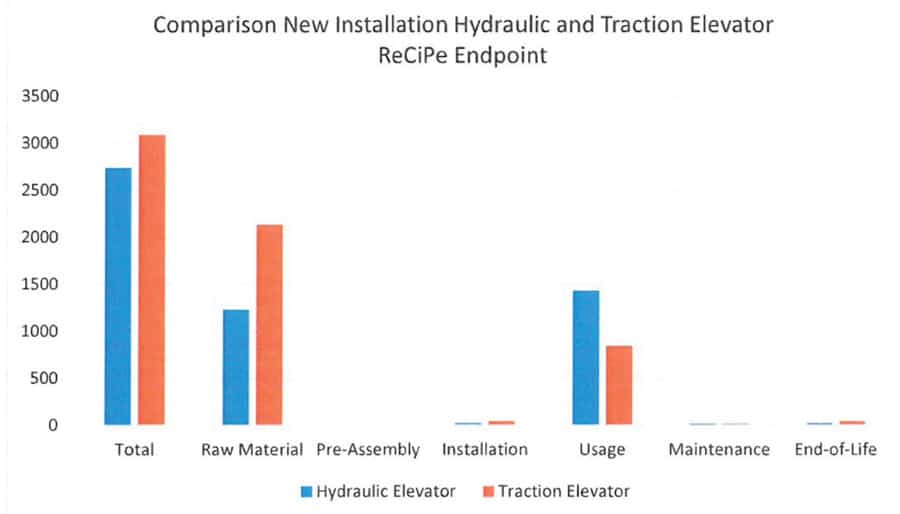

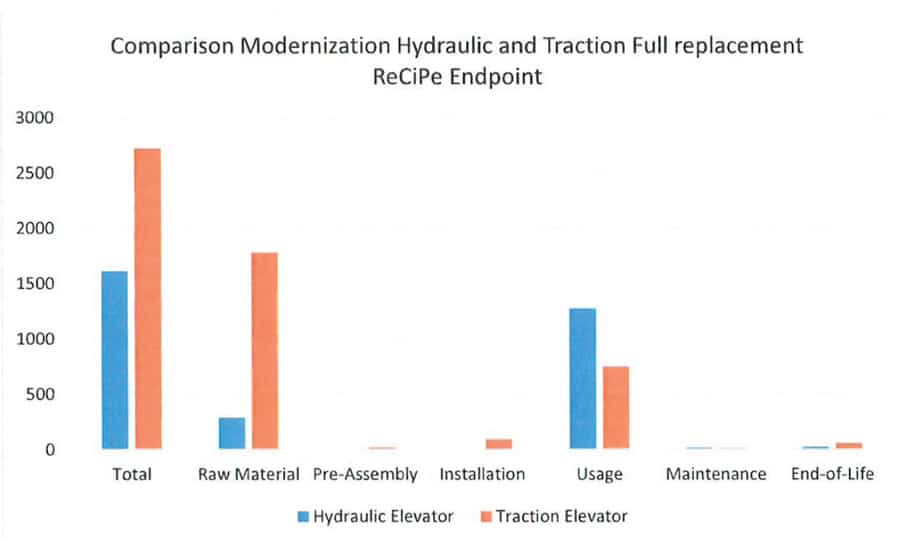

A recent study by Hydroware Elevation Technology AB of Sweden on new elevator installations and modernizations for low-usage lifts (averaging 50 trips per day; www.hydroware.de/lib/get/file.php?id=155f9221554af7) clearly showed that hydraulic elevators are much more environmentally friendly than traction ones. Figure 4 shows comparisons of environmental impacts for new installations (hydraulic and traction). The total environmental impact for hydraulic elevators is 7% less than that of traction ones. In Figure 5, environmental impacts are compared between hydraulic elevator modernization (usage category 1) and the full replacement of a hydraulic elevator with a traction one. Therein, the environmental impact with the traction elevator is 43% higher. More results of new LCAs on modernization will be announced by a European Lift & Lift Component Association hydraulic working group.

In general, hydraulic elevators are much more reliable than traction elevators. Therefore, their maintenance generates much less impact. Hydraulic elevators, having fewer components with high-performance capability, all working in a lubricated environment, have longer lifecycles and less downtime, resulting in significant cost savings. In addition, the most expensive spare part of a machine-room-less traction elevator is greater than 30% of the total elevator cost, while that figure is 4–6% for a hydraulic elevator. These statistics were calculated only via regular service visits; adding breakdowns and repairs would probably increase traction-elevator impact even more. These results show that for low-usage elevators, full replacement of hydraulic elevators with traction ones would be disastrous for the environment.

Get more of Elevator World. Sign up for our free e-newsletter.