Impact of EN 81-20 and EN 81-50 Standards

May 1, 2015

This paper was presented at  Paris 2014, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 20, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers

Paris 2014, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 20, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers  (website: www.elevcon.com). This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

(website: www.elevcon.com). This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

ABSTRACT

Main European standards for lifts, EN 81-1 for electric and EN 81-2 for hydraulic, have been revised! There are many changes to the requirements of those standards and the result will be published as EN 81-20 and EN 81-50 standards.

The new and revised requirements of EN 81-20/50 improve safety of lifts for passengers and workers, while the new format and removal of the redundancies in the content of those standards make them easier to apply.

Technical requirements of EN 81-1/2 are widely accepted around the world. During the revision process, much effort has been made to collect needs, requirements and requests from the users of those standards and incorporate them into EN 81-20/50, thus facilitating the worldwide harmonization of the technical requirements for lifts.

Implementation of EN 81-20/50 requires many changes to the current design of the lift installations. It is beneficial for all stakeholders to know about those standards and timely align their products and processes accordingly.

This paper provides an overview of EN 81-20/50 development and the possible impact of those standards to the design and installation of lifts around the world.

1. INTRODUCTION

EN 81-1, safety rules for the construction and installation of electric (traction) and EN 81-2 for hydraulic form the foundation of the European EN 81 series of standards for lifts. They are the main harmonised standards providing presumption of conformity to the essential health and safety requirements of the European legislation for lifts, Lifts Directive (95/16/EC), establishing the reference for the level of safety for any lift installations in Europe.

In addition, the technical requirements of EN 81-1/2 standards are the basis for national safety standards for lifts in many countries outside Europe, which makes those standards globally relevant.

EN 81-1/2 standards have been developed by the European Committee for Standardization, Technical Committee 10 (CEN/TC 10) and they have been subject to regular amendments and revisions since their first publication in 1977 (EN 81-1) and 1987 (EN 81-2), improving and evolving with each of their new edition. Experience gained in application of the standards, introduction of new technologies and regulatory changes have been the key input for revision of those standards.

The latest revision of EN 81-1/2, resulting in two new standards as EN 81-20/50, has been the most comprehensive revision since the publication of those standards.

2. EUROPEAN STANDARDIZATION FOR LIFTS AND ESCALATORS

2.1 European Committee for Standardization (CEN)

CEN is an international non-profit association based in Brussels, created on 30 October 1975. CEN is a major provider of European Standards and technical specifications in all areas of economic activity with the exception of electrotechnology (CENELEC) and telecommunication (ETSI).

More than 60.000 technical experts as well as business federations, consumer and other societal interest organizations are involved in the CEN network. CEN has published and currently maintains more than 15000 documents and more than 3000 documents are in preparations.

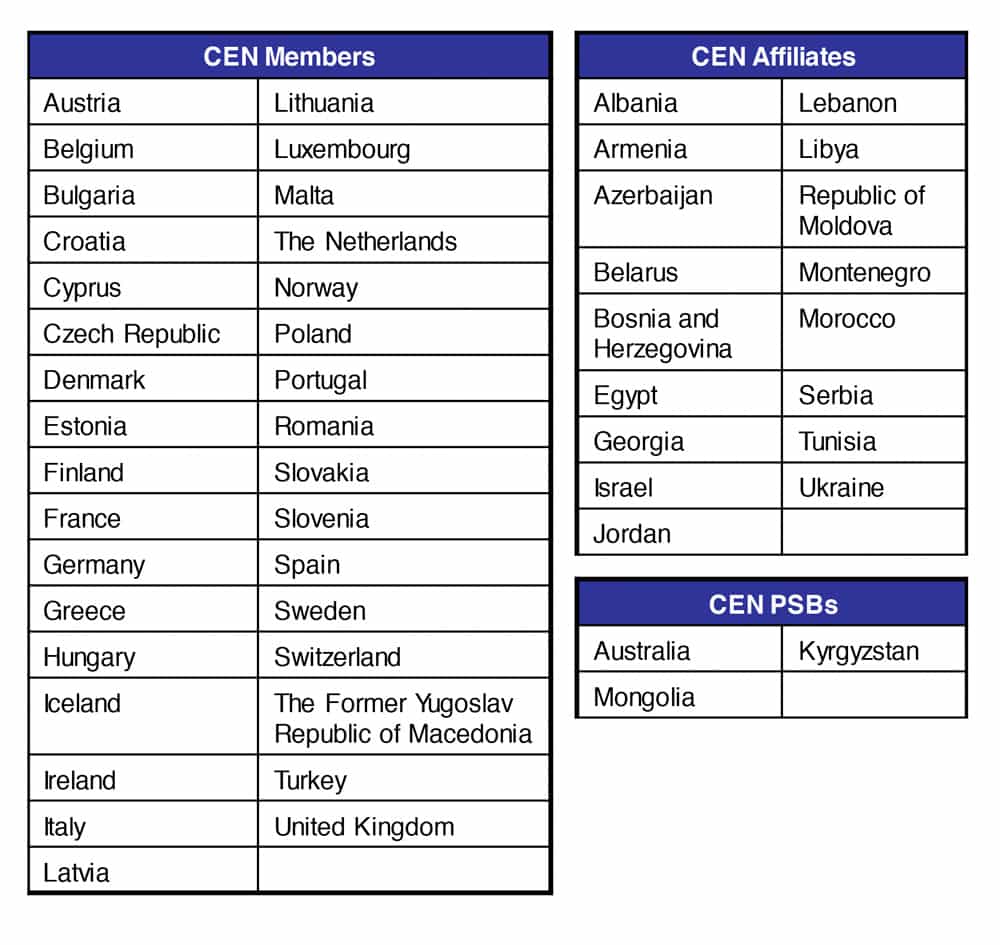

CEN members are National Standardisation Bodies from 33 countries which work together to develop European Standards (ENs). These standards have a unique status since they become national standards in each of the 33 member countries. With one common standard in all these countries and every conflicting national standard withdrawn, a product can reach a far wider market with much lower development and testing costs.

In addition, 17 affiliate countries may participate in the standardisation work as observers, as well as 3 Partner Standardisation Bodies (PSOs) which maintain a close relationship and cooperation with CEN. Table 1 shows the CEN members, affiliates and PSOs.

The Vienna Agreement, signed by CEN and ISO (International Organization for Standardization) in 1991, ensures technical cooperation between two organisations. The forms of cooperation include by correspondence, mutual representation at meetings and coordination meetings, adoption of the same text, as both an ISO Standard and a European Standard.

In addition, CEN has signed cooperation agreement or memorandum of understanding with numerous national and regional standardization organisations around the world.

This provides opportunities and facilitates exchange of information, knowledge and experience among the experts, thus enriching the content and convergences of the requirements of the standards.

More information on CEN may be found at www.cen.eu.

2.2 CEN/TC 10

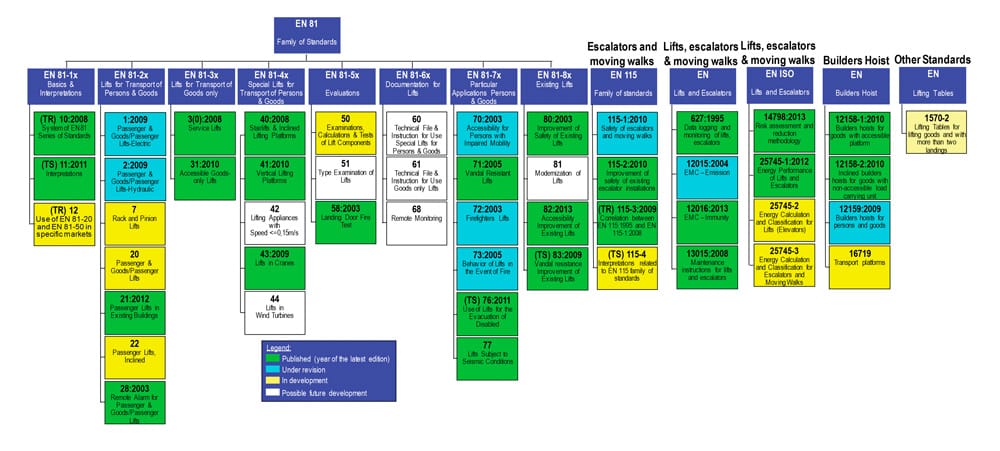

CEN/TC 10 is the oldest Technical Committee in CEN, created in 1971. CEN/TC 10 is responsible for development and maintenance of the European standards for lifts and escalators. CEN/TC 10 work program is carried out in several work groups.Table 2 shows the structure of the CEN/TC 10 organisation.

The current work program of CEN /TC 10 consists of 36 standards, 4 technical specifications and 3 technical reports. The work program covers all aspects of lifts and escalators. Table 3 shows a general overview of CEN/TC 10 work program.

More information on CEN/TC 10 and current status of its work program may be found at www.cen.eu.

3. EN 81-20 AND EN 81-20

EN 81-1/2 standards, since their last edition published in 1998, have been subject to several amendments. Amendment (1), which covers requirements for Programmable Electronic System in Safety Related Applications for Lifts (PESSRAL), was published in 2005 and Amendment (2), which covers the Machine-Room-Less (MRL) lifts, was made available in 2003.

Due to the changes to the European legislation, Machinery and Lifts Directives, and due to a worldwide attention and need to address the Uncontrolled Car Movement (UCM) protection, the Amendment (3) was developed and published in 2009.

CEN/TC 10 decision on revision of EN 81-1/2 was taken in 2003. Considering that such revision should include the comprehensive review of the standard, a detailed preparatory work was planned.

Recognising the high level of interest from the countries outside Europe, several meetings and seminars were held in order to obtain understanding of the needs and requirements of the non-European stakeholders.

3.1 Main drivers for revision of EN 81-1/2

CEN/TC 10 carried out a comprehensive study, identifying the main drivers for the revision the standards as:

- Comments received from the European interest groups, such as legislators or trade associations

- Comments and requests received from non-European users of the standards provided during the technical exchange meetings or by correspondence

- Result of the codes and standards harmonisation work carried out by the ISO/TC 178

- Result of studies and experiments carried out by the safety research organisations, for example door strength tests by KESI (Korea Elevator safety Institute)

- Legislative changes, especially the European Lifts and Machinery Directives

- Incorporation of EN 81-1/2 interpretations into the body of the standards

- Outstanding comments from the previous edition of the standards

- Application of the standardisation guidelines on child safety, accessibility for all and environmental protection

- Need to improve the ease of use and future maintenance of the standards

As the result of the preparatory work, more than 700 items of revision were identified!

To carry out the work, the relevant working groups within CEN/TC 10 were activated and the draft of the revised standards was completed in the end of 2011. After the full approval process, i.e. CEN Enquiry and Formal Vote, the result of the revision will be published as two new standards, EN 81-20/50, in July 2014.

3.2 Safety improvements

Based on the preparatory work, several key safety improvements were identified, addressed and incorporated into EN 81-20/50. Main changes and improvements to safety provisions of the standards includes, for passengers:

- Higher requirements for strength of landing and car doors

- Prevention of the doors striking the persons entering or exiting the lift car

- Higher level of lighting inside the lift car

- Specific guidance for considering mass of devices used for loading and unloading of the lift car

- Higher requirements for strength of the lift car walls

- Prevision against possibility of falling into the lift well due to self-rescue by the entrapped passenger

- Higher requirements for rescue of the trapped persons

- And for workers:

- Higher requirements for the refuge spaces on the car roof and in the pit

- Higher requirements for the balustrades on the car roof

- Higher requirements to prevent risk of trapping on the car roof or in the pit

- Higher requirements for the size and location of the landing door unlocking device

- Higher requirements for the pit access ladders

- A control station in the pit for avoiding the use of ladders and stools to reach the car components for inspection of maintenance operations

- Specific requirements for over-connecting the car or the landing door contacts during the maintenance operations

3.3 International dimension

Technical requirements of the EN 81-1/2 standards are the basis of national standards in many countries outside Europe. Therefore, those standards have a global importance and relevance that must be taken into account in any amendment or revision made to those standards. CEN/TC 10 has been aware of such importance and decided to invite and facilitate participation of experts from the non-European countries at the very early phase of the project.

Utilising the current mutual cooperation agreement between CEN and ISO organisations, CEN/TC 10 invited experts from ISO/TC 178 to join this work. ISO/TC 178 responded favourably and experts from China, Korea, Japan and the United States were nominated. In addition, close cooperation between CEN/TC 10 and PALEA (Pacific Asia Lift and Escalator Association) facilitated access to many Asia Pacific countries and get better understanding of their needs and requirements.

In order to facilitate the participation from the ISO experts, a specific working group, AH17 (Ad Hoc Group 17) was formed. This approach made it possible to hold the meetings in other locations than Europe and closer to the home country of the ISO participants.

AH17 has been actively involved in preparation of the draft of the standards and during the CEN Enquiry (Public Enquiry) AH17 members were also invited to provide comments. As a result, CEN/TC 10 received comments from 14 countries outside Europe! All those comments have been threated similar to comments from European countries. AH17 has also provided comments during the Formal Vote.

CEN/TC 10 and ISO/TC 178 approach for involving non-European ISO member countries in developing EN 81-20/50 served two main mutually beneficial objectives; first to ensure that the standards satisfy the needs of those countries, as much as possible, and the second to facilitate the adoption of the requirements of the standards in those countries. This is a major step forward towards the ISO/TC 178 objective of harmonising technical requirements for lifts around the world.

4. CEN/TR 81-12

Based on the comments received during the EN 81-20/50 public enquiry, CEN/TC 10 has identified several aspects of EN 81-20/50 which are different within the national standards of the non-European countries. For example, the average weight of a person varies from 65kg to 75kg within those national standards.

Although such variation does not affect the safety of the lift, but it creates difficulties, for example, with the traffic analysis or the content of the load plate in the lift car, when relating the rated load to the car floor area and to the number of passengers.

Another example is the differences in the national building regulations that may influence the implementation of some of the clauses of EN 81-20.

CEN/TR 81-12 titled as “Use of EN 81-20 and EN 81-50 in specific markets”, is a new document providing guidelines on addressing such issues. In addition it provides a table of comparison for clause numbers of EN 81-1/2 and EN 81-20/50 to assist with adoption of the new standards.

Publication of CEN/TR 81-12 has been an opportunity to provide some explanation on the basics of EN 81-20/50, for example importance of “assumptions” in the standard or understanding the meaning of commonly used standardisation terms such as “shall”, “should”, etc.

CEN/TR 81-12 is planned to be published together with EN 81-20/50.

5. IMPACT OF EN 81-20/50

5.1 Harmonisation of codes and standards

CEN/TC 10 has taken every possible step for involving stakeholders and interested parties around the world, collecting their comments and requirements and incorporating them into the EN 81-20/50, as much as technically possible and within the limited time available.

These standards may satisfy need of many countries worldwide, and as such, EN 81-20/50 may present a big step in direction of harmonisation of codes and standards around the world and may put the foundation for a global standard for lifts.

5.2 Safety and accessibility

EN 81-20/50 includes many improvements for safely of the lift passengers and workers alike. Considering the wide use of those standards, such improvements will be implemented in many countries in the world almost simultaneously.

5.3 Ease of use

Simplification of the content of the EN 81-20/50 standards by removing redundancies and reformatting the text has made it easier for the users to find the information they may need.

5.4 Frequent updates and improvements

This comprehensive revision of EN 81-1/2 and development of EN 81-20/50 has been a learning experience for all parties involved. Valuable lessons have been learnt in terms of methods of identifying the needs and requirements of the users of the standards, involving and engaging all stakeholders, as well as timely communication on progress of the work and the revised content of the standards. Those lessons will be put into practice in the future amendments and revisions of the standards.

CEN/TC 10 intends to make regular improvements to EN 81-20/50 in the future, in close coordination with all stakeholders. Those improvements will be made in such a way that they may cause the least disruption to the products and processes or affecting the harmonisation of the standards.

For example, adding new technologies in fulfilling the requirements which widens the coverage of the standards without affecting the compliance of the current products design.

The first amendment of EN 81-20/50 is being planned. After a maximum of three amendments, the standards will be revised comprehensively to align their requirements with the state of the art and progress in the safety concepts and provisions.

6. IMPLEMENTATION OF EN 81-20/50

Implementation of EN 81-20/50 may require changes to several components of lifts, such as lift car and landing doors or lift car structure. It may also have influence in the design of the buildings and dimensions of the lift well.

Therefore, it is highly recommended to align the current design of the products to EN 81-20/50 requirements in a timely manner.

7. CONCLUSIONS

EN 81-20/50 has been developed with close cooperation and involvement of the stakeholders and interested parties worldwide, bringing many changes including many improvements for the safety of passengers and workers for lifts.

Implementation of those standards will greatly improve the level of safety and will also provide an opportunity for a greater harmonisation of the codes and standards around the world.

Application of EN 81-20/50 standards may require changes to the current design of lifts and the relevant documentation. The lift industry as well as the inspection bodies and other related trades may need to make timely preparations for adoption of the requirements of those standards.

Table 1. CEN members, affiliates and PSBs

Table 3. CEN/TC 10 work program

Get more of Elevator World. Sign up for our free e-newsletter.