Innovative Designs: Challenges for Inspection and Maintenance?

May 1, 2020

New technology is frequently introduced, but safety regulations don’t always cover changes.

by Robert Kaspersma

This article was first presented at the 2019 International Elevator & Escalator Symposium in Las Vegas. For more information on December 7-8, 2020’s event in Amsterdam and to participate, visit www.elevatorsymposium.org.

New elevator designs are regularly introduced, yet safety regulations do not always cover them. This means it is important to have all the risks covered. New designs involve new maintenance and inspection methods. It is the manufacturer’s responsibility to ensure that, with development of new designs, proper inspection and maintenance can be performed. The starting point is a risk assessment, or failure mode and effects analysis. The results of this assessment or analysis are converted to procedures normally covered in product manuals. Therefore, it is essential these manuals are always present at the installation, even when the maintenance company changes. This brings up a new challenge: new designs need to be able to be maintained by other companies, to keep them conforming properly. Certification of these new designs by a Notified Body (NB) or Accredited Elevator/Escalator Certification Organization (AECO) should not only cover the original design, but also proper maintenance and inspection.

Introduction

The first elevators were introduced in the early 1800s. Technology has changed a lot since. Still, the elevator industry is one of the most conservative. The reason is personal safety. The elevator is considered one of the safest means of transportion. The first elevator safety standards were introduced around 1916. The industry wanted to ensure elevators had a minimum safety level to ensure a safe ride.

Compared to the old days, elevator development has sped up over the past 30 years. One of the reasons is the introduction of new regulations in Europe. With the founding of the European Union, member states looked for a way to provide minimum safety requirements without limiting product design. The so-called “Directives” described a uniform design and approval process for different product groups without defining the exact way to achieve a specified safety level.

One of the first Directives was the Machinery Directive. The Lifts Directive (LD) was published in 1995. At the same time and in anticipation of the new regulations, KONE developed the machine-room-less (MRL) elevator. The manufacturer had basically eliminated the machine room and installed the machine in the hoistway and controller on the topmost landing. To maintain market position, other manufacturers followed suit. In the next sections, three innovative designs will be discussed: MRL elevators, new suspension means and programmable electronic safety systems (PESS).

MRL Elevators

KONE introduced the MRL elevator in 1996. The unique design of the motor (pancake) made it possible to install the motor between the guide rails. The drive and controller were installed at the topmost landing. This first MRL elevator was certified by Liftinstituut according to the LD.

Builders and architects loved this design, because the ugly bump on top of ding was no longer necessary. As with many new designs, many parts and ideas were patented, which limited other manufacturers’ ability to copy it.

Eventually, other major manufacturers developed their own MRL designs. Otis came first with its Gien 97, followed by Gien 99, and, later, in combination with the introduction of new belts, the GEN2® elevator. Schindler developed the 3300/SMART elevator, and thyssenkrupp developed the ISIS and Evolution. All these new elevators had special features, which made maintaining them more complex and product-specific.

Maintenance and Inspection

What all these new elevators had in common was lack of a machine room. This was the space where the elevator engineer was able to put his tools, keep spare parts and do paperwork. Above all, it was a place where he was able to maintain the elevator without being disturbed. As you can imagine, MRL elevators bring risks, so a careful evaluation should be performed to determine where they are suitable and at which floor the controller and drive should be installed.

The elevator industry is a strange one, in the sense that the person/company buying a new elevator is not its final owner. Therefore, sales arguments valid for the initial buyer may not have the same benefits for the final owner/end user.

With the new designs, some new maintenance concepts were introduced. We see this in the consumer market, as well. If a part is broken, it is not repaired, but replaced completely.

The main components of the elevator are the controller, drive, motor/machine and suspension means. These parts are normally replaced rather than repaired. Regardless of elevator type, inspection and maintenance must be performed, and, if the elevator is stuck, people must be evacuated.

The document on which an engineer is relying in the field is the maintenance manual. This document explains how to perform maintenance and, above all, provides instruction on how to perform these tasks safely. Nowadays, one of the key features is the use of a task risk assessment or last-minute risk assessment. The engineer must review whether or not the task to be performed can be performed safely.

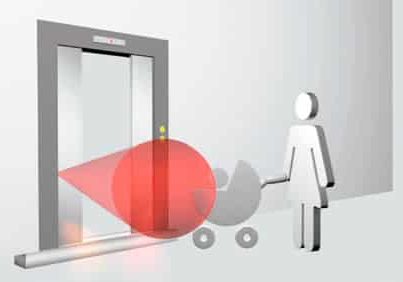

The same applies to performing inspections. It is the task of the inspector to verify the elevator is safe. All required tests must be performed from the landing, and the result must be monitored from a screen. Normally, there is not a direct view of the machine. Only the first generation of MRL elevators had a window in the controller to look at the machine, but the added value was limited.

What is the task for the manufacturer and designer? The elevator must comply with the essential health and safety requirements. These can be found in LD 2014/33EU Annex I, ISO 8100-20 or ASME A17.7/CSA B44.7.

According to ISO 8100-20:2018, when designing a lift or its components, a review of the intended use, foreseeable misuse (see ISO 14798:2009, Section 4.5.5.4) and the design shall be made, in which all possible risk scenarios are formulated. Risk assessment should be performed to find out which, if any, global essential safety requirements are applicable to the design. All risk scenarios that can occur during operation and use, as well as during maintenance or inspection, of the lift shall be considered. As an NB/AECO, it is our task to make sure this is done correctly. The standard/directive mentioned above states instruction shall be provided to perform the tasks needed to keep the elevator safe.

EN 81-20 and A17.1/B44 describe what needs to be tested during the initial inspection. These tasks must be performed from a safe location, and test results need to be verified. Periodic tests in Europe depend on local regulations, but the initial tests can be used as guidelines.

Alternative Suspension Means

Another big development in the elevator industry is the introduction of belts. Belts have a big advantage: due to their minimal thickness, smaller-diameter sheaves can be used. This saves space in the hoistway. A timeline of the development of alternative suspension means is shown:

- 1999: Otis introduces the GEN2 belt. Otis introduced its new type of suspension means in combination with its MRL elevator, GEN2. Instead of normal wire ropes, which have a thickness of 8 or 10 mm, a belt was made by basically taking the standard rope apart, and putting the individual strands next to each other and coating them with polyurethane.

- 2000: Schindler announces its aramid fiber rope. This rope has an outer shell of polyurethane. Inside are multiple (140,000) aramid fibers. Compared to steel wire ropes, aramid ropes are four times lighter and have a lifespan four times longer. Due to the ropes’ lightweight construction, travel heights of more than 1,000 m can be reached. The light weight also means machines can be much smaller, because the total moving mass is less.

- 2004: thyssenkrupp introduces K-Core rope. In North America, thyssenkrupp introduced Kevlar® ropes on its ISIS MRL elevator. These were similar in construction to aramid ropes.

- 2007: Seattle Children’s Hospital, accident at a children’s hospital in Seattle in October. The Kevlar ropes of the ISIS elevator were severely damaged and broke, sending the car into freefall and activating the safeties. Many, if not all, Kevlar ropes have since been replaced by conventional steel wire ropes.

- 2008: Schindler announces its Suspension Traction Media (STM).

- This is Schindler’s second innovation after the aramid rope. STM has steel cords coated with polyurethane material.

- 2010: ASME publishes A17.6. Based on the experiences of elevator and rope manufacturers, a standard was developed for the safe use of steel wire ropes, aramid ropes and elastomeric-coated steel belts.

- 2013: KONE introduces UltraRopeTM, which has the same objectives as aramid rope. Contradicting its name, UltraRope is a belt. The belt consists of four carbon fiber bars. Due to the lightweight construction, travel heights of more than 1,000 m can be achieved.

- 2018: thyssenkrupp introduces belts on its new EVO product. Steel wire ropes have been used since elevators’ early days.

Even the safety requirements for ropes in A17.1 date back to the early years of code. Inspection and discard requirements are described in specific industry standards. These new types of suspension means all have an outer shell of polyurethane in different colors. No standards exist. So, the big question is: When do these new types of belts/ropes need to be replaced to ensure elevator passenger safety?

What most of these products have in common is they have been certified by an NB and, later, by an AECO. During this certification, an equal safety level has to be proven. The safety level is basically set by the standard or norm valid at the time.

These products were not covered in this standard. Today, belts are still not covered by the latest version of the elevator standard in Europe, EN 81-20. However, work is in progress, and it is likely that, in a few years, these alternative suspension means will be covered by EN 81-20. One of the criteria to be proven during certification is when to replace the suspension means. Otis introduced the Pulse to avoid replacement every five years (an original criteria in the first certificate). Schindler had carbon fiber elements in its aramid rope to provide information on wear. UltraRope is made of carbon fibers, so KONE also measures rope wear. Schindler STMs have slack belt switches, which do not cover wear.

Schindler and thyssenkrupp tested the belts and counted the number of bends and trips to create a correlation between the remaining breaking strength and number of trips/bends. The controller keeps track of the number of trips and informs the maintenance engineer when to replace the belts. If this is not performed in time, the controller switches the elevator off.

PESS

The introduction of PESS in elevators is still pretty new. Some manufacturers have introduced drives that include some electronics, but not all are considered PESS. KONE introduced the first full PESS for a complete elevator system. thyssenkrupp introduced PESS with its innovative TWIN elevator system, which has two cars operating independently in one hoistway, sharing the same guide rails. These systems have to be considered black boxes with safety inputs and outputs. The standard to follow is IEC 61508, which consists of seven parts that explain how to design and evaluate a safety system. It also explains when the system needs to be certified, but, according to the LD, all PESS are required to be certified by an NB.

Certification

Around the world, when the design of an elevator deviates from the local standard, the manufacturer must ask permission to install it. Standards are not able to keep pace with the development of new elevator designs.

When performing a certification, Liftinstituut and other Notified Bodies look at the product not only from a safety point of view, but also how to keep the installation safe and in working order during the lifetime of the elevator. The LD sets a minimum elevator lifetime of 10 years, or it basically states that all the documentation shall be kept by the manufacturer/installer for a minimum of 10 years. NB is currently required to keep the documents regarding the certification for a minimum of 15 years. Liftinstituut still has almost all the documents related to our certifications.

So, what is certified? The elevator or component itself, of course, but the manuals are essential, too. For MRL elevators, the manuals must explain how to perform maintenance safely and how to inspect the elevator. For alternative suspension means, maintenance involves a visual inspection for damage to the polyurethane coating or signs of deformation. Replacement normally takes place when damage to the suspension means is significant enough or the controller tells the technician to replace the suspension means. This can be based on a measured value by an electronic system or on a number of trips and/or bends.

For PESS controllers and/or drives, it is complicated, because, as stated previously, you look at a black box. The system has built-in self-tests to check for correct operation. The system normally has a special test mode to allow the elevator to be tested. During tests, it will allow certain safety contacts to be bridged without utilizing an actual jumper. This improves safety because the bridging occurs only in test mode and, normally, only once during the actual test. An engineer has to fully rely on the system readouts. Therefore, a certification is essential. During the certification, all the possible failures and strange combinations will be tested.

Maintainability and Inspectability

To develop a new elevator is one thing. To keep it running in good order requires regular maintenance and inspection. With standard elevators, the basic principle of the product is similar, which means the maintenance of a KONE and an Otis elevator are not that different. An engineer who could read an electrical diagram and has basic mechanical knowledge could come a long way.

Nowadays, with all the different designs around, electronic engineers are needed to handle the controller, and material scientists are needed to verify the status of new suspension means unless, of course, the maintenance manual and inspection manual enable you to do that, as they should. Besides the complexity of new elevators today, there are a few other things that complicate their maintenance and/or inspection:

- All new systems are patented to prevent them from being copied. On the other hand, secrecy is gone, because patent applications are public, so everybody knows what everybody else is developing. This product protection is also applied to manuals, so the information is shared on a need-to-know basis only.

- The complexity of the elevator market: Maintainability is not a big concern of the initial buyer. Price level is a bigger deciding parameter. So, elevator companies lower the selling price and try to make up for their loss in maintenance contracts.

- Because elevator market competition is fierce, companies look for ways to bind their customer to their product. To hold onto maintenance contracts, companies have to develop elevators that can only be maintained by their maintenance company.

Still, big and small owners with multiple brands of elevators want to use one maintenance company. This means elevators are maintained by a different company from the original supplier. If the maintenance company changes, the first local strategy of the original maintenance company is to remove all the manuals and additional elevator information. These documents officially belong to the owner: he/she has paid for the elevator, including all the corresponding paperwork. For special features or innovative products, these documents are essential to perform correct and safe maintenance and inspections.

Conclusion

During the past 25 years, elevator designs have changed. New products were introduced to please the buyer. MRL elevators reduced the headroom of the hoistway, new suspension means enabled smaller pulley diameters and reduced required pit depth with underslung elevators. This, in turn, reduced energy levels due to the lower weight ratio.

For maintenance engineers and inspectors, jobs have become much more complicated. Both now have to know many different products. These people need information to perform their tasks. The right method for providing this information is a manual, preferably a paper version (not a CD or USB drive that can be stuck away in a closet). They also need assurance that, if the maintenance company changes, this information stays with the elevator.

References

[1] liftinstituut.com

[2] asme.org

[3] kone.com

[4] otis.com

[5] schindler.com

[6] thyssenkruppelevator.com

Get more of Elevator World. Sign up for our free e-newsletter.