Inspection, Replacement of Ropes

Dec 1, 2020

1- Introduction

Replacement of different types of ropes such as, traction ropes, compensation rope, overspeed governor ropes depends, mainly on the wear, which happened in wires. The rope consists of definite number of strands, each strand (composed of known number of wires) according to the type of rope, and their twist in spiral form to give lay of the rope (ordinary lay or Lang’s lay).

Since, there are different types of ropes in market, the manufactures must give definite and distinguished characteristics of ropes, on which the visual inspection which carried out by the competent person will give the right decision, whatever the ropes must be change or not?

The basic criteria’s for replacement ropes are:

First criteria: reduction of rope’s diameter.

Second criteria: crown wire break.

Third criteria: valley break.

2- Definitions

a) Reduction of the nominal diameter of steel ropes

The reduction of the rope’s diameter is the main criteria, on which the competent person decides whatever the rope change or not?

b) Crown wires break

Wires wear happened in the part of the rope which contact directly with the traction sheave. Consequently, the wear in the crown wires of the strand increases. When visual inspection is carried out by competent person, hecan determine the number of broken wire.

c) Valley breaks

Valley wires are located in the valley of two adjacent strands and are not in contact with the traction sheave.

The wear produced from the friction between the adjacent stands and between the wires in the same strand.Valley breaks are attributed to rope fatigue.

d) Unfavorable condition

It means excessive wear of individual wires in the strands due to unequal tension, poor sheave grooves, or environmental conditions….etc.

Wire pitch (lay length of strand)

One wire pitch is the distance in which an outer layer wire make a spiral , for one wire pitch of (9) outer layer wire amounts to the total distance of the (9) wire.

f) Rope pitch (lay length of the robe)

One rope pitch is a distance of an outer layer makes a spiral, one rope pitch of (8) strand rope amounts to the total distance of (8) strands. The number of the broken wires within a rope pitch is an inspection criteria to determine rope deterioration.

3- Inspection and replacent of steel wire ropes

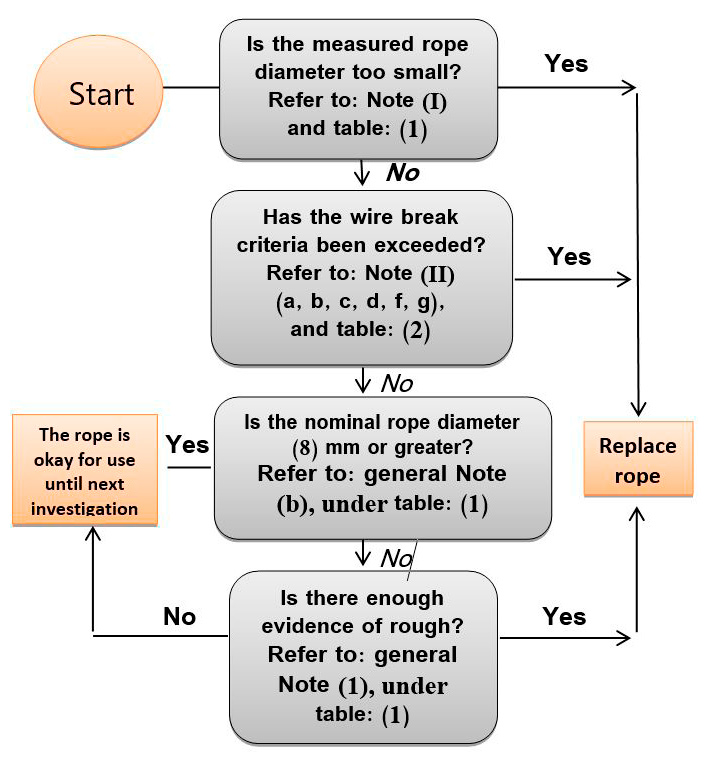

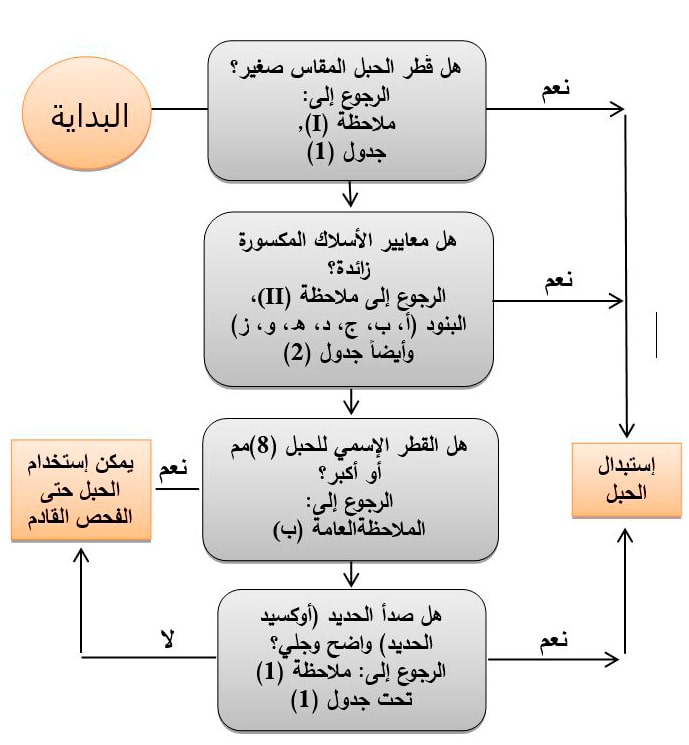

The flowchart in figure (1) can be used to show the steps for inspection and replacement of steel wire ropes. The first and major step: Is the measured rope diameter too small, compare to nominal diameter? If the answer is yes, the rope must be replace, if not – then complete the next step and so on ….

4- Notes of flowchart

4.1 Note I

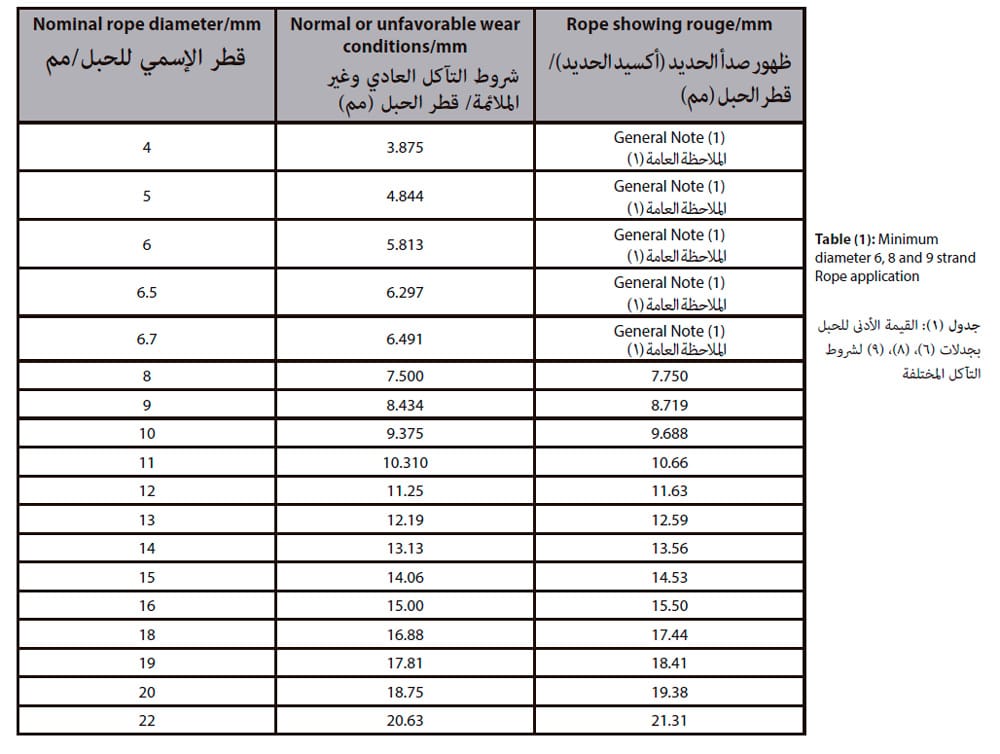

The suspension, compensation and over speed governor ropes shall be replaced when their actual measured diameter is reduced below the values given in table (1). For ropes with nominal diameter not listed in this table, the minimum diameter reduction shall be calculated, using the notes mentioned under table (1), for different condition: Normal, unfavorable wear and rope showing rouge.

4.2 Note II

Replacement of the rope must be carried out, if the visual inspection includes at least one of the following:

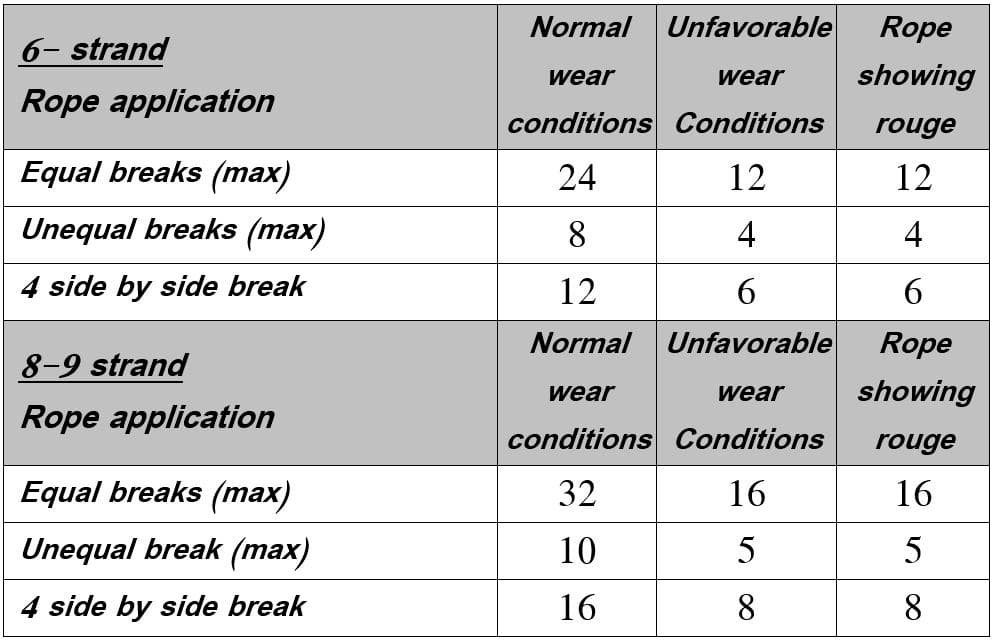

- If the broken crown wire are equally distributed among the strands, when the number of broken wires per rope lay (rope pitch) in the worst section of rope exceeds the values shown normal wear condition in the first column of table (2).

- If the distribution of breaker in unequal and broken crown wire predominate in one of two strands, when the number of broken wires per rope lay in the worst section of rope exceeds the values shown in the “Normal wear conditions, first column of table (2).

- If four wires, side by side, are broken across the crown of any strand, when the number of broken wires per rope lay in the worst section of ropes exceeds the value shown in the normal wear condition “First column of table (2)”.

- If an unfavorable condition exists, the criteria for broken crown wires will be the values indicated in the “unfavorable conditions” second column of table (2).

- In red dust exists, the criteria for broken wires will be the values indicated in the “Rope showing rough”, third column in table (2) for any of the conditions described above.

- If there are more than one valley break per rope lay.

- g)If there are any valley breaks at any location where rough exists.

5- The minimum diameter of ropes

The first stop in flow chart (fig [1]) related to how much the nominal diameter is small? Table (1) shows the value of minimum diameter for ropes of 6,8 and 9 strands in normal, unfavorable conditions and rope showing rouge. In regular inspection, if the measured diameter is below that given in table (1), rope must be replaced.

General Notes

(a) Maximum allowable diameter reduction below nominal for rope diameter less than (8)mm is 3.125% for normal and unfavorable wear conditions.

(b) Maximum allowable diameter reduction for rope diameter equal to or greater than (8)mm are as follow:

(1) Normal wear or unfavorable wear condition is 6.25%.

(2) Rope showing rouge is 3.125%.

Note (1): For ropes less than (8)mm, the rope must be replaced when there is evidence of rouge.

6- Wire breaks

As shown in flow chart fig (1), the second step related to has the wire break criteria been exceeded definite numbers? These maximum numbers are listened in table 2, for 6, 8, and 9 strands, and for the mode of break: Distributed, unequal and side by side. The ropes must be replaced if at least one of conditions from (a) … to (g) is achieved (Note II).

Wire breaks

(a) Where ropes are subjected to reverse bends or where ropes are installed on non-metallic coated plastic, fiber- reinforced plastic sheaves, or sheave with nonmetallic liners or inserts, extra attention must be given to any steel wire (6, 8, or 9 strands) due to possible acceleration of valley breaks.

(b) No more than one valley break per lay length and no valley breaks allowed if visible rouge.

(c) For ropes less than (8)mm diameter, shall be replaced when there is evidence rouge.

7- Conclusion

The visual inspection, which is carried out by competent person, is very important to determine whatever the rope must be replace or not. In regular maintenance,the competent person test and check the performance of the rope during operation. If he found one of the criteria mentioned in this article: reduction or rope diameter, crown wire break valley wire break, the rope showing rouge, according to the conditions mentioned in tables (1), (2), then the rope must be replace.

References

1- ASME A 17.1/CSA B44.

2- Technical data DRAKO-GOSTAV WOLF.

3- Mitsubishi Electric Building Techno – Service Co. Ltd

Get more of Elevator World. Sign up for our free e-newsletter.