Intelligent Inspection of Elevators

Mar 1, 2014

Nondestructive testing of safety equipment without the use of physically damaging and clumsy test weights

Reprinted from Lift-Report

There are systems available that now allow elevators to be tested more accurately and efficiently without weights. What matters, above all, is correct detection of all influencing factors in order to carry out a proper calculation of the full-load test result. A major factor is the influence of the counterweight at the exact instant the safety gear is triggered. The patented methods and sensors of the Henning ELVI system allow elevator safeties to be evaluated with a nondestructive testing process. Adding weight to the car only serves to further stress the people conducting the test and the elevator safety equipment being checked, and also causes unnecessary wear and tear to the complete elevator cabin and system.

Elevators are the world’s safest means of public transportation. High-quality design, specific standards during fabrication and tests carried out at regular intervals make sure accidents caused by technical failures are practically nonexistent. One- and five-year testing intervals adopted worldwide guarantee the safety of passengers, operators and manufacturers of passenger lifts. What is tested and exactly how it is tested are really the greater concerns.

The time when recurring elevator inspections require literally tons of weights to be hauled around is coming to an end. The elevator-maintenance company saves valuable time and money, the coordination of deadlines is easier, and, more importantly, damages caused during testing are minimized. The testing of elevators without using test weights is now established in the market for recurrent inspections. As early as 2003, Henning Testing Systems GmbH presented an intelligent testing system that has been widely distributed in Germany, Austria and across Europe. It is also now in Canada and the U.S., in the wake of code authority and market acceptance. The ELVI elevator-inspection system, with its patented measuring methods, allows an effective and equipment-sparing test process that can be carried out with a high level of safety. All components and testing sequences of the ELVI system have been independently validated by Zentrum für Förder und Aufzugstechnik Rosswein.

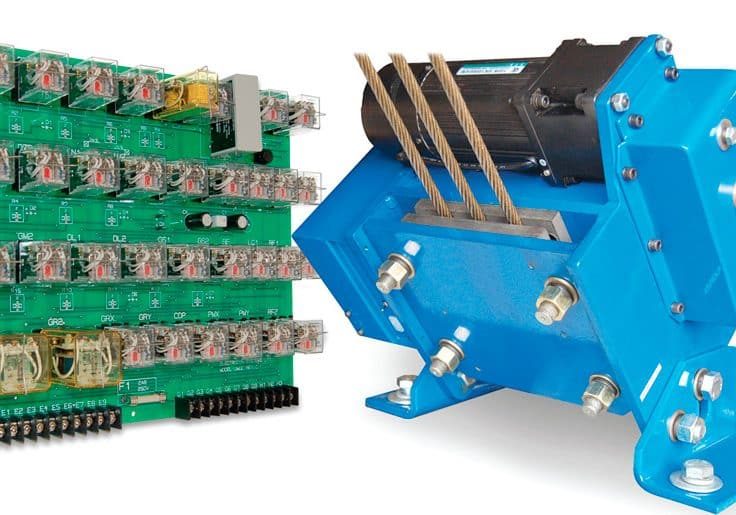

In addition to testing the efficiency of the elevator safeties, the system also evaluates friction, the machine brake, weight of counterweight (CWT) and car weight, and carries out the half-load test. Individual rope tensions are exactly determined, too, and can easily be adjusted afterward. This protects suspension ropes, traction sheaves and deflection pulleys against wear and, thus, improves overall equipment and public safety, and minimizes unnecessary future expenses. There is no need for test weights and for manipulating the elevator’s mechanics, electrics or electronics; the overall testing procedure with ELVI is quickly completed in one go (less than 30 min.). An elevator technician with basic understanding of conducting emergency stops and some training in using this testing system is all that is required.

Correct Testing by Weight Measurement

The exact weights of the car and CWT, measured by Henning’s patented rope-load sensors, are important for the evaluation of the safety of an elevator system. Experience has shown that the documented weights available on site are often quite unreliable, especially for modernized elevator systems and systems under extended maintenance periods; this is also sometimes the case with new systems. These weights are essential input figures needed to establish the brake force of the safety gear: wrong input figures will calculate potentially unreliable and dangerous results. Exact actual weights are needed to permit exact calculation of the expected behavior of the safety gear in the event of an emergency (a loaded car in freefall) and, further, to meet the standards of EN 81-1 for brake-type safety gears.

Physically Correct Freefall Statements

Checking the efficiency of the safety gear without using known and correct weights involves a major risk with respect to the test statement, since the effective brake (holdback) force of the CWT is really unknown. Numerous tests have proven that the braking effect the CWT has on the car can decisively support the efforts of the safety gear (verified by ELVI or another similar test system). One might think that at the time the safety gear is tripped, the CWT does not act upon the safety gear. But, it quickly becomes apparent that – independent of the car load condition – this can be a dangerous assumption: numerous spring elements in the elevator system (not least the suspension ropes) may have the effect that the influences of the counterweight are not felt until several tenths of a second have passed. By this time, the car has usually come to a halt, predominantly because of the counterweight’s assistance. If one takes a look at the worst case (freefall), the CWT is no longer there; it has lost its connection (ropes) to the elevator cabin (car).

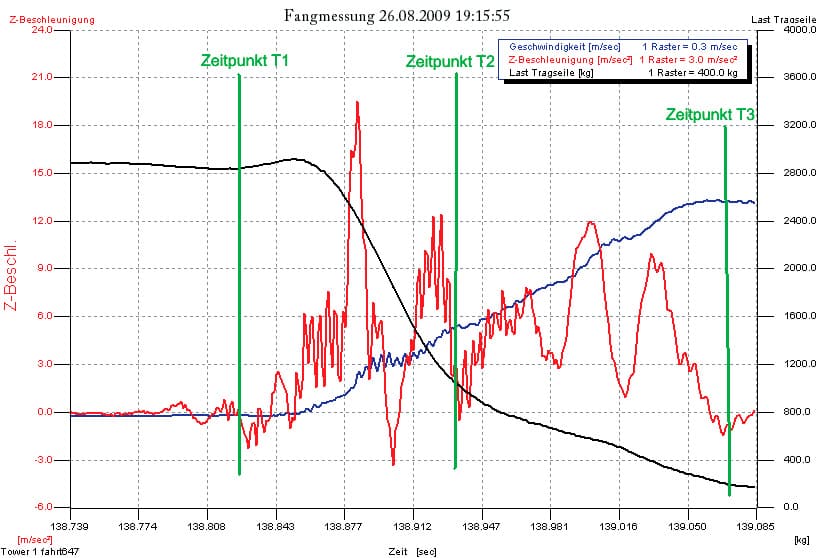

The sample measurements, shown in Figure 2, will help make this clear. This actual test result shows the low-pass-filtered acceleration, the load measured in the suspension ropes (influence of the counterweight) and the speed at the time the safety gear is tripped.

One can see that during the entire safety-gear operation (T1-T3), the force in the suspension ropes is continuously reduced (black curve). At the beginning of the engagement of the safeties, the force is 28 kN. At time T2, when the car has already been decelerated to half the tripping speed of the overspeed limiter, the force is still 10 kN. Even at the end of safety-gear operation, it is still 2 kN.

Should this force be neglected, an arithmetical delay of the fully loaded car in freefall of 12 mps2 (approximately 1.2 g) would result. The measured result would clearly be wrong. In a freefall, there would actually be a delay of 3 mps2 (approximately 0.3 g), which, in this particular elevator system, will, fortunately, prevent serious injuries. Unfortunately, numerous tests carried out with the ELVI system have also revealed elevators, without the supporting forces of the counterweight in a freefall situation, that would not have been able to have the car safely decelerated by means of the safety gear. This, to be sure, is the ultimate reason for conducting the test! The cars of these systems would have accelerated more and more, before crashing into the bottom of the pit, when full weights and speed conditions of a freefall would have occurred.

It is crucially important to exactly determine the influences of the CWT on an empty car during the inspection of the safety gear. This is what the ELVI system and rope-load sensors were designed to accomplish. It is possible to calculate the conditions for the loaded car in a freefall situation. The influences of the counterweight and/or motor are directly measured so the ELVI system can measure the effectiveness of the safeties of elevator systems at random rated speeds – including reduced speeds. During safety-gear operation with an empty car, the forces in the ropes are constantly measured so a statement can be made at any time about the counterweight force that supports the tested safeties in decelerating the car. The ELVI system, therefore, allows the actual brake force of the safety gear to be exactly determined and its effect exactly calculated for the catastrophic emergency case (when a fully loaded car is in freefall).

Conclusion

This presentation of safety-gear measurement using the ELVI system clearly shows the benefit of electronic systems, compared to using simple, but heavy, weights and measuring slide distances in the inspection of an elevator system. An electronic testing system capable of measuring the influences of the CWT in the course of safety-gear operation can make a clear statement with respect to the requirements of the EN 81 standard. This is not possible if one uses test weights. A test carried out with weights does not allow a statement to be made about the way in which the CWT supports the safety-gear operation; the CWT is potentially a very massive supporting force, which would not exist in a freefall situation.

Get more of Elevator World. Sign up for our free e-newsletter.