A look at the history behind InnoTech Manufacturing, LLC (ITM) and the products it provides

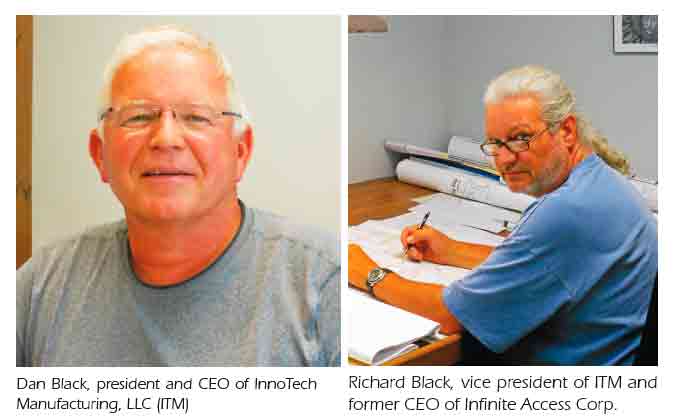

InnoTech Manufacturing, LLC (ITM), headquartered in Mount Vernon, Illinois, was founded in 2009. ITM, run by President and CEO Dan Black and Vice President Richard Black, is a metals-manufacturing company. Richard Black, former CEO of Infinite Access Corp. and inventor of the AC3000 modular elevator, joined forces with his cousin Dan Black in 2008. With more than 70 combined years in the construction industry, the principals of ITM have consistently made innovations that save time and resources for various construction projects.

History

In 1994, operating as Infinite Access, the corporation introduced one of the first modular accessibility ramp systems, which were distributed, sold and installed across the U.S. In 1998, the company revolutionized portable construction steps, the design of which 90% of steps manufactured today mimic. Meanwhile, they had been perfecting the product for which they originally set forth to manufacture – the elevator hoistway system, now known as the InnoShaft. In June 2000, the U.S. Patent Office issued a patent for the AC3000 modular elevator.

In April 2008, Richard Black closed Infinite Access to collaborate trades with Dan Black in plans of starting a new company. The company, known as ITM, picked up where Infinite Access left off in 2009 with a renewed mission to design, engineer and manufacture products that alleviate problems and issues common to the construction industry. ITM expanded company operations in November 2011 and acquired two new locations. It also installed overhead cranes in two fabrication shops to sustain increased production.

Products

The elevator products ITM offers include elevator hoistways (InnoShaft), machine rooms, elevator entrances, cabs and components. The InnoShaft was designed to help save contractors’ time and money. The system can be set up in as little as 2 hr., compared to the two to four weeks for traditional masonry shafts. These factory-built modular shafts can be used in both retrofit and new-construction jobs. The hoistways can be applied both indoors and outdoors manufactured for all brands of elevators. The self-supporting hoistways can reach up to 50 ft. high and are stackable up to 150 ft. high, with lateral support coming from the building structure. Machine rooms are manufactured with the same integrity as the hoistways, meeting or exceeding all applicable building and ASME A17.1 codes. As with the elevator shafts, the machine rooms are shipped via flatbed trucks from the factory to the jobsite.

ITM’s elevator cabs range from simple, economical passenger cabs to industrial freight cars and luxury cabins. At its manufacturing facility, ITM designs, fabricates and preassembles all elevator-cab components. ITM’s trained craftsmen are skilled in working with metal, wood, glass, stone, resins and laminates to produce high-quality elevator cab interiors.

Elevator entrances are offered in various configurations, such as single- or multi-speed side sliding and single- or multi-speed center opening. Frames are offered fire rated or unrated as needed (1 1/2 hr.). ITM finishes range from #4 stainless steel, #4 and #8 muntz and Kynar®-coated. Each door panel has a removable finish skin, making refinishing easy. Standard entrances can usually be shipped in four to six weeks from receipt of approval. ITM also welcomes custom designs and sizes.

German precision Computer Numerical Control equipment enables ITM to economically produce door panels. Door inner skins are heavy duty, 16-gauge, stretcher-leveled steel, designed to be rugged. Panels requiring fire-rated labeling are available (1 1/2 hr). Various drilling patterns, such as GAL Type A or MAC, are available for existing applications.

ITM’s complete hoistway fascia and support systems are manufactured from heavy-gauge galvanized steel and include sill supports, struts, headers, dust covers, fascia panels, wall brackets and clips, toe guard, and all hardware to assemble (expansion or wedge anchors by others). Tolerant alignment elements are intended to facilitate easy, fast installation. Many components are universal helping enable a fast shipping schedule.

Sump covers, pit ladders, divider beams, rail brackets, sill angles, car-top guardrails and other products are manufactured by ITM for use in the elevator industry. ITM designs and manufactures its components in a way to maximize efficiency.

Get more of Elevator World. Sign up for our free e-newsletter.