ThyssenKrupp installs the first iwalks in the U.K.

Since 1955, Heathrow Airport has been connecting people from around the globe, making it one of the world’s busiest international airports. Situated west of London, it is the U.K.’s largest airport with 245,000 passengers arriving and departing on more than 1,200 flights every day. The airport, with its five terminals, is home to some 82 airlines that provide flights to 180 cities in 885 countries. Terminal 5, an addition opened in 2008, has been rated one of the best in Europe.

In recent years, GBP11 billion (US$17 billion) has been invested in improving Heathrow. This is one of the largest private-sector investments in U.K. infrastructure – improving customer service, as well as providing jobs and supporting the country’s economic growth. Looking forward to 2019, more upgrades and expansions will continue to improve the airport.

Heathrow Airport had to avoid, if possible, the need for pits at a level that was already well below ground level and, therefore, susceptible to water ingress.

Tunnels, known as the Track Transit Walkways (TTWs), lie beneath the underground Track Transit System (TTS). Passengers can use them to reach terminal sections 5B and 5C by foot. Installing passenger conveyors into these two walkway tunnels was a challenge for Heathrow Airport Limited (HAL), the airport operator. It had to avoid, if possible, the need for pits at a level that was already well below ground level and, therefore, susceptible to water ingress. After scouring the market for suitable products, HAL contacted ThyssenKrupp, which was able to offer its pit-less iwalk product. After many months of discussions, ThyssenKrupp was awarded the contract to provide 13 iwalks to the TTW, which links Terminal 5’s main building, T5A, to its two satellite buildings, T5B and T5C. These are the first iwalks to be installed in the U.K.

Challenges

This project presented the team with a number of challenges.

- The site was located inside the airside boundary. Not only was this logistically challenging for the delivery of the iwalk sections and associated parts, but the entire project team had to be equipped with passes for airside work.

- The actual site was split between two separate tunnels, each approximately 1/2 mi. long, for arrivals and departures with no access between them, except at the ends.

- The TTS walkways remained open to the public while both the delivery of the iwalk sections and assembly and testing were undertaken. This required all works to be undertaken behind a boarded area. Coordination between ThyssenKrupp and the main contractor was critical to allow boardings to be available when iwalk works were carried out.

- The iwalks were delivered via elevators from the airport’s apron level down to the TTS walkway level. This required the iwalk sections to be manufactured in smaller lengths – 3,350 mm at the most – than the standard 5,715 mm. Therefore, special redesign and manufacturing were required.

- Due to an extremely tight schedule to complete the project in time for the official opening of the TTS walkways, other refurbishment works were required in the walkway tunnels while the iwalks were being installed.

Because the iwalk section lengths were reduced from the standard size to fit inside the elevators, there were 1,660 individual sections delivered to the site.

Solutions

As part of the tender negotiations, representatives from the Spanish escalator and moving-walk factory, ThyssenKrupp Norte, visited the site to determine the requirements. Detailed surveys and measurements were taken to ensure the iwalks were designed and manufactured to the correct lengths to suit the layout of the tunnels.

The surveying of the site also identified a potential route to get the iwalk sections down to the walkway via a series of elevators that traveled between the apron level and TTS walkway. Passengers also used these elevators to transport their luggage using buggies; so, the ThyssenKrupp design team concluded the solution would be to redesign the modular iwalk sections to a length that fit inside the elevators. Adopting this method eliminated other routes that would have caused much more disruption to the airport’s operations.

Back at the factory, the iwalks were released for manufacturing on June 1, 2013. After six weeks of working on the modules’ redesign to a smaller length at ThyssenKrupp Norte, which involved relocating some of the main-drive-system parts and the complete redrawing of the balustrade, among others, the necessary drawings and bill of materials were fully completed. Then, the procurement process through the materials-requirement-planning control system was carried out.

Six weeks later, the first materials started arriving at ThyssenKrupp Norte facilities to be inspected by the Quality department, and, after that, they were incorporated into the manufacturing process for the final assembly of the sections under the constant oversight of the Quality and Engineering department and the project manager at ThyssenKrupp Norte, Juan Antonio Fernández. On October 25, 2013, the first iwalk for Terminal 5 was loaded in a truck and left ThyssenKrupp Norte for Heathrow.

The Test

The site works started in earnest in mid November 2013. Then came the time to see if the months of planning would work and if the iwalk sections would fit inside the elevators as planned. They did, so the ThyssenKrupp Airport Services team – which operates within the airport installing and maintaining air bridges – delivered and installed the iwalks. They were delivered to the site via a client-owned and -operated logistics facility specifically developed to control deliveries to the airport. They were offloaded at the apron level by the use of a Hiab crane fitted to the delivery vehicle.

The sections were loaded directly onto platform lift trucks that had been specially designed and manufactured for this project. The platform lift trucks, which allowed the sections to be tilted 45˚, aided the maneuvering of the iwalk sections into the elevator, through the terminal and along the respective tunnels to their final locations, where they were installed in place using lifting frames.

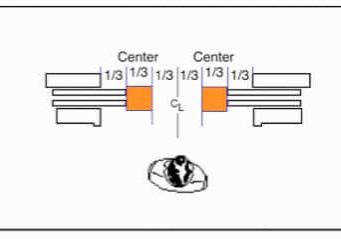

In order to give HAL personnel access to doors and passageways linking the two tunnels, the iwalks had to be set approximately 1 m away from the walls. Once all the sections were in place and joined together, the site team lined and leveled the complete iwalk. The next stage was to assemble the balustrades, fit the inner and outer decking’s cladding, fit the specially manufactured passenger-emergency-stop posts and carry out the final testing and commissioning of each iwalk.

Because the iwalk section lengths were reduced from the standard size to fit inside the elevators, there were 1,660 individual sections delivered to the site. During assembly, the guidance systems on each section had to be filed by hand to achieve a perfect and smooth transition between sections. To say the least, this was an extremely time-consuming activity.

When the site team recessed for Christmas in 2013, only three of the 13 iwalks had been assembled. Although three more had been delivered and installed, and another three were on their way, it was recognized that, with only eight weeks left, a revision to the plan was required to meet the end date. The project manager of ThyssenKrupp Elevator U.K., Mel Lewis, called a meeting with the key members of the team, who eventually came up with a plan that included some changes to the assembly methods and additional shifts on weekends. The plan also required isolation of the moving walks’ fire alarms so as to allow some hand grinding, rather than filing by hand.

While it was a tough program to maintain, the site team met the challenge. Assembly and testing of the final iwalk was completed in time for the February 2014 completion date. In order to comply with strict specification requirements, technical and environmental inspections were undertaken by both the main contractor and HAL. The iwalks passed each of these inspections, and, on the day they were officially opened to the public, Terminal 5 head of Engineering and Facilities Alan Russell said, “ThyssenKrupp has successfully delivered a product that perfectly suits the requirements of the TTS walkways. We are pleased to have the iwalks as part of our airport terminal.”

Opposite page, top to bottom: maneuvering the iwalk sections through the terminal; iwalk assembly

Get more of Elevator World. Sign up for our free e-newsletter.