An examination of the industry exploits of “the pioneer of the elevator business in Canada”

by Dr. Lee Gray, EW Correspondent

The history of the recent past occasionally has an unintended consequence — it conceals the history of the more distant past. A search for information on a given topic may reveal useful material that unintentionally obscures or directs attention away from important prior events. This phenomenon often occurs in historical investigations, particularly in the internet era. For example: a search for the terms “Fensom” and “elevator” yields a wealth of information on Otis-Fensom Elevator Co., which played an important role in Canada’s vertical-transportation (VT) industry in the first half of the 20th century. However, behind this “more recent history” lies the story of John Fensom (1829-1908) and the 19th century Canadian company whose success made Otis-Fensom possible.

The Fensom family emigrated from England to the U.S. in the early 1840s. After brief periods spent in Rhode Island and Massachusetts, they moved to Canada in 1846. John Fensom began to learn the machinist trade during this time. In the late 1850s, he opened a machinist shop in Toronto and began to seek ways to distinguish himself from his competitors. One event he used to great effect was the annual exhibitions of the Agricultural Association of Upper Canada. In 1859, he was awarded his first “Diploma” award for a “hand printing press.” This was followed by a second in 1862 for a “machine for cutting and mitering printers’ rules” and a “First-Class Prize” in 1866 for “best turning lathe.”

Fensom’s second (and primary) means of attempting to ensure commercial success was to patent his designs, a strategy that typically involved simultaneously pursuing patents in Canada and the U.S. Between 1869 and 1873, he patented a copy press, two lathe designs, a machine for making bricks and artificial stone, and an elevator safety device. The eclectic nature of these patent topics is typical of many 19th-century machinists who saw themselves as capable of designing and building almost anything. This perceived versatility was evident in an 1870 advertisement, in which Fensom described himself as an “engineer, machinist, etc.” capable of furnishing “plans and estimates for all kinds of mills and manufactories, including engines, shafting, pullies, gearing, hangers and all the latest machinery required in all kinds of manufacturing.”[1] In 1871, Fensom opened Central Iron Works in Toronto. Advertisements for the new business included references to the full range of services noted above, as well as an important new product: hoisting machinery.

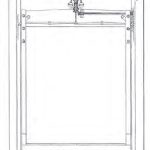

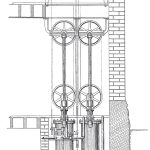

While it is likely that Fensom built hoists for industrial use prior to 1871, his decision to advertise this fact may have been prompted by an increased interest in this technology. In October 1871, he filed patent applications in Canada and the U.S. for an improved safety device. The Canadian patent was awarded in 1871, but the American patent office delayed their approval until 1874. The patent concerned a safety designed to prevent the car from attaining “a greater velocity than usual.”[2] Fensom’s design employed a flyball governor driven by a shaft connected via pinion gears to a rack attached to one of the guide posts (Figure 1). If the car exceeded a preset speed, the action of the governor pushed bars into “ratchet-racks” attached to each guidepost, which stopped the car. Thus, its action was like that of numerous contemporary designs, including Elisha Graves Otis’ 1861 patent. In fact, Fensom’s patent text made it clear that he was aware of Otis’ patent:

“In all hoists or elevators with which I am familiar, the safety-gear cannot be depended upon, being either too complicated or not attached in the proper position. The machine, which has been most generally adopted in the U.S., is arranged so that, should the hoisting rope break, catches fly into ratchet-racks and prevent the cage falling; but, should the driving-belt slip off, or any other accident occur, except the breaking of the rope, the safety attachment would not have the slightest effect, but would permit the cage to fall as though the hoisting rope had broken. There are other arrangements I am aware of for overcoming this difficulty, but they are all misapplied or too complicated to be of any use. My safety attachment will not only prevent the cage falling should the hoisting rope break but will also support it should anything occur to the machinery which would otherwise cause it to fall.”[2]

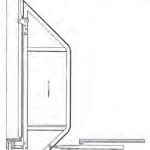

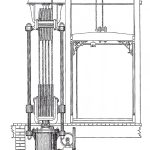

Fensom’s second elevator patent, for a self-closing hatchway system, addressed another common industrial safety concern (Figure 2).[3] His awareness of contemporary elevator technology and innovations was also reflected in his next three patents, all of which concerned hydraulic elevators.

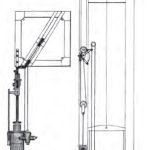

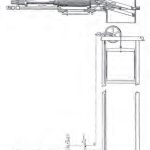

His first hydraulic elevator system was patented in Canada in 1875. (Fensom may have also applied for a U.S. patent, though no evidence exists to support this.) He employed a simple horizontal engine that was similar in design to American linear hydraulic systems in which the plunger was directly connected to the hoisting rope. In this case, the rope was attached to a series of pulley blocks that multiplied its action in raising and lowering the car (Figures 3-4).

Fensom described his design as suitable for use “in factories, hotels and stores, and also for the raising of materials in the erection of buildings, and other purposes.” His design included “an instrument which registers the exact quantity of water used in its operations” and a valve designed to allow the amount of water used to be proportional to the load lifted.[4] In 1876, one of his hydraulic elevators was included in the Canadian display of industrial goods at the Centennial Exhibition in Philadelphia. Unfortunately, no description of this elevator has been found.

One of the first descriptions of a Fensom hydraulic installation dates from 1877 and concerns passenger and baggage elevators in Toronto’s Rossin House. The hotel was substantially remodeled with the goal of making it “one of the best hotels on the continent.” According to a contemporary newspaper account:

“The most important of these alterations is the erection of commodious passenger and baggage elevators, which will relieve guests of the fatigue attendant on an ascent of the long stretches of stairway. . . . The elevators are to be worked by hydraulic pressure, the safest motive power that has yet been devised for such purposes, because of the easiness with which it can be controlled, stopping with the slightest touch on the check line. . . . The elevating apparatus was all manufactured by Mr. John Fensom, engineer, of this city, and is on the same principle as that used in large hotels [in NYC]. It is of the largest kind and is the only one we know now in use in this province.”[5]

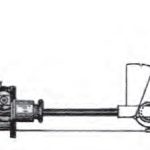

This installation may have utilized a vertical hydraulic engine design patented by Fensom in 1878. This system employed “a water-cylinder of known lifting capacity” combined with “one or more supplementary water cylinders arranged in connection with [a] suitable automatic mechanism to be thrown in and out of working connection as the load on the hoist is increased or diminished.”[6] (Figures 5-6)

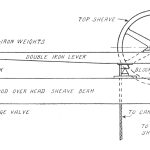

Fensom’s next patent also concerned a means of varying the hydraulic pressure used in proportion to the load carried.[7] This system employed what became known as the Fensom Balancing Device, which was sufficiently well-known to be included in John Jallings’ 1918 Elevators: A Practical Treatise on the Development and Design of Hand, Belt, Steam, Hydraulic and Electric Elevators (Figure 7). Jallings described the device in the context of the history of hydraulic elevators:

“John Fensom of Toronto, Canada, had developed the scheme of using a circulating pipe connecting the front and back ends of a horizontal machine in such a way that the water, after being used for hoisting, was discharged on the lowering trip into the other end of the cylinder, and then, on the next up trip, was forced into overhead tanks for use about the building. To take care of the heavy loads, he set the bearing boxes of his overhead sheave on the end of a lever pivoted on knife edges similar to those used with the levers of large platform scales. . . . When a heavy load was placed on the car or platform of the elevator, it would lift the long end of the lever, having overbalanced it and the weight attached. The long end of this lever had, connected to it, a small cable or a thin rod running down to a pipe laid underground and connected to the sewer. This rod or cable was attached to a valve set in the pipe, and when, through an overweight on the platform, the lever was raised, it opened the valve in the pipe and allowed the discharge water to run to waste, thus relieving the piston of back pressure and allowing the elevator to lift the heavy load. Hence, it was only while lifting light and medium loads that water was economized. It was found in practice, however, that the discharge water from these machines, owing to the necessarily frequent use of lubricating oils inside the cylinders, was too foul and greasy to be suitable for any other purpose, and the idea was abandoned.”[8]

The patent illustrations depicted the load-balancing device employed on a typical horizontal hydraulic system (Figure 8).

In 1883, Fensom’s success led him to close Central Iron Works and open Fensom Elevator Works, which he advertised as “manufacturers of hydraulic, steam and hand power elevators, with all the modern improvements.”[9] Two years later, it was reported that he employed approximately 25 and had a thriving business.[10] Unfortunately, no detailed list of Fensom elevator installations has been found; however, contemporary Canadian governmental publications provide ample evidence that he furnished elevators for civic buildings across Canada. These commissions included the design and construction of an elevator at Niagara Falls in 1887. The elevator was intended to improve:

“. . .the comfort and convenience of visitors wishing to experience the sensations produced by a trip under the ‘Sheet of Water,’ [which] required other and better facilities than the toilsome descent and ascent of the circular wooden stairway presently in use. . . . [Therefore,] it was decided to erect a powerful hydraulic vertical lift. . . . The preparation for and erection of a work of this kind, within the scope of the spray’s most potent influence, was an onerous one, which only those who have experienced its paralyzing effects can appreciate. But Mr. Fensom, of Toronto, an experienced builder of every variety of lifts, to whom this work was entrusted, has succeeded in accomplishing the task. . . . The lift is sufficiently large to accommodate eight to 10 visitors with their accompanying guides, and occupies but three-fourths of a minute in the upward or downward journey. The car runs in an open wrought-iron tower of great strength and stability. . . . The water required to work the lift is brought in large pipes from the river above the falls, a distance of some 400 ft. . . . Owing to the extraordinary accumulation of ice on all exposed objects in the immediate vicinity of the falls, it was found necessary to encase the iron tower in which the lift runs with tight wooden shutters, having glazed openings for admission of light. These shutters will be removed in summer, affording on three sides an unobstructed view, and visitors will be able to enjoy the unfolding of the magnificent panorama as they gently glide down, in the open cage, to the pathway under the overhanging cliffs, by which they are conducted behind the falling waters.”[11]

This high-profile commission was followed in 1888 by another important project that, upon completion, resulted in Fensom finding himself in an unusual — and perhaps uncomfortable — position.

In 1883, the Canadian government began construction of a significant new building in Ottawa, which, when completed in 1889, was named the Langevin Block. (In 2017, the building was renamed the Office of the Prime Minister and Privy Council Building). It was originally designed to house the Departments of Agriculture, Interior, Indian Affairs and Post Office (in the 1970s, the building was renovated to house the Office of the Prime Minister and the Privy Council). The building’s design included three passenger elevators and one freight elevator. The call for proposals was published in mid-August with tenders (bids) due on September 17, 1888. Three companies submitted bids: Crane Elevator Co. of Chicago (CAD46,543

[US$34,178]), Hale Elevator Co. of Chicago (CAD39,877 [US$29,283]) and Fensom Elevator Works (CAD41,972 [US$30,822]). At some point between September 17th and September 25th, Fensom submitted a revised bid, which lowered his price to CAD39,877 (matching that of the lowest American bid), and the contract was awarded to Fensom on October 10, 1888. Three years later, he found himself testifying before a Select Standing Committee investigating the construction of the Langevin Block.

Fensom’s appearance before the committee was not, however, due to his bid changing to ensure a better chance of receiving the commission. It was because of the circumstances surrounding the bidding process. Fensom had traveled to Ottawa to visit the office of Thomas Fuller, the building’s architect, to review the specifications to prepare his bid. The specifications included the following clause:

“Each party or firm must furnish with tender a guarantee to have the contract completed within a specific period, after it is awarded him or them; and that he or they will make arrangement with the contractor for the building for space required for workshops, storage and material, etc., and will hold himself or themselves responsible for any damage that may occur to any portion of the building during the progress and up to the completion of his or their contract.[12]

Fensom was informed that, as was stated in the specifications, he must first meet and “make arrangements” with Alphonse Charlebois, the building’s general contractor, prior to submitting his tender or bid. Fensom was informed at the meeting that he was required to add 25% to his bid, which, if he were awarded the contract, was to be paid directly to Charlebois. The payment was “required” to ensure access to the building site and ample workspace, help pay for a night watchman, and allow Charlebois to make up lost profits. Fensom testified that he had never before been asked to increase his bid to pay a general contractor for the right to work on a project. Fortunately for him, the remainder of his career was devoid of Parliamentary investigations.

Throughout the 1890s, he continued to expand his business and range of elevator products. In 1889, he began to manufacture Bostwick folding steel gates and guards, and by the end of the century, he was manufacturing ornamental iron and grille work for elevator shafts. By the mid-1890s, he had also added electric elevators to his product line. Fensom opened the new century by taking direct aim at his American competitors in a lengthy two-page advertisement:

“Much ado has been made lately about the commercial invasion of Europe by the U.S. In the modern office building recently erected in Port Elizabeth, South Africa, by the Mutual Life Insurance Company of New York, Fensom’s ‘One Grade’ elevators are installed. In the Washington Monument and many other U.S. institutions, Fensom’s designs have been utilized. In most of the public and private buildings throughout the Dominion, where the elevators are working perfectly, they will be found to be of Fensom design and manufacture.”[13]

The statement that “many” American institutions “utilized” Fensom designs deserves greater attention in a future article. For example, no reference to Fensom’s overt involvement in the Washington Monument has been found; however, his statement clearly implies a connection.

This proud claim of the company’s overseas expansion was John Fensom’s last word as an elevator manufacturer. He retired in 1903 just as Fensom Elevator Works was transformed into Fensom Elevator Co. The new company was, however, short lived. In 1905, it was purchased by Otis, and, following its merger with the Canadian Otis Elevator Co., its name was changed to the familiar Otis-Fensom Elevator. Upon Fensom’s death in 1908, the author of one of his obituaries proclaimed that his death marked:

“. . .the passing away of the pioneer of the elevator business in Canada and one of the most conspicuous figures in the industrial circles of the Dominion for many years. During his extended career along the lines of useful endeavor and accomplishment, Mr. Fensom was closely identified with the progress of the country, and he won for himself an enviable position among the nation’s manufacturers.”[14]

These laudatory comments in recognition of Fensom’s extraordinary career serve as a reminder of the historical (and occasionally national) importance of the VT industry and its members.

- Figure 1: Fensom’s safety device (1871)

- Figure 2: Fensom’s self-closing hatchway design (1873)[3]

- Figure 3: (l-r) Plan and shaft elevation of Fensom’s horizontal hydraulic elevator (1875)

- Figure 4: Elevation of Fensom’s horizontal hydraulic elevator engine (1875)

- Figure 5: Elevation of Fensom’s vertical hydraulic elevator engine (1878)

- Figure 6: Elevation of Fensom’s vertical hydraulic elevator engine (1878)

- Figure 7: Fensom’s 1878 Balancing Device[8]

- Figure 8: Plan and elevation of Fensom’s horizontal hydraulic elevator with balancing device (1878)

References

[1] Guide Book of the City of Toronto, Toronto: Bell, Barker & Co. (1870).

[2] John Fensom. “Improvement in Hoists or Elevators,” Canadian Patent

No. 1,111 (October 25, 1871) and “Improvement in Elevators,” U.S.

Patent No. 151,014 (May 19, 1874).

[3] John Fensom. “Improvements in Hoists,” Canadian Patent No. 2,329

(April 23, 1873) and “Improvement in Self-Closing Hatchways,”

U.S. Patent No. 165,554 (July 13, 1875).

[4] John Fensom. “Hydraulic Elevator,” Canadian Patent No. 5,025 (July

24, 1875).

[5] “The Rossin House,” Wisconsin State Journal, Madison, Wisconsin

(May 24, 1877) (originally published in the Toronto Leader).

[6] John Fensom. “Improvements on Hoisting Machine,” Canadian

Patent No. 8,380 (February 1, 1878) and “Improvement in Hoisting

Machines,” U.S. Patent No. 209,336 (October 29, 1878).

[7] John Fensom. “Improvements on Hoisting Machine,” Canadian

Patent No. 9,394 (October 22, 1878) and “Improvement in Hoisting

Machines,” U.S. Patent No. 217,600 (July 15, 1879).

[8] John Jallings. Elevators: A Practical Treatise on the Development and

Design of Hand, Belt, Steam, Hydraulic and Electric Elevators,

American Technical Society: Chicago (1918).

[9] The Toronto City Directory for 1883, R.L. Polk & Co.: Toronto (1883).

[10] History of Toronto and County of York Ontario, Vol. 1, C. Bracket

Robinson: Toronto (1885).

[11] “Report of the Commissioners of the Queen Victoria Niagara Falls

Park for the Year 1887,” Sessional Papers, V. XX, Part V, Second

Session of Sixth Legislature of the Province of Ontario, Session 1888,

Warwick & Sons: Toronto (1888).

[12] Select Standing Committee on Public Accounts. Reports, Minutes of

Evidence and Exhibits in Connection with the Langevin Block,

Brown Chamberlin: Ottawa (1891).

[13] The Toronto City Directory, Vol. 27, Might Directories, Ltd.: Toronto

(1902).

[14] “The Late Mr. John Fensom: One of Canada’s Industrial Pioneers,”

Construction, Vol. 1, No. 11 (September 1908).

Get more of Elevator World. Sign up for our free e-newsletter.