La Muela II Hydroelectric Power Plant

Jan 1, 2016

ThyssenKrupp Elevadores embraces an underground challenge.

Valencia, Spain

submitted by Begoña Flores Canseco, thyssenkrupp elevator

La Muela II Hydroelectric Power Plant lies on the right bank of the Júcar River in Cortes de Pallás, Valencia, Spain. It serves as the largest pumped-storage hydroelectric power plant in Europe and the most important use of hydroelectric power in the Iberian Peninsula. Iberdrola Generación S.A. built the plant in its endeavor to develop new facilities that generate clean energy capable of meeting peak-time demands.

The Big Dig

The plant meets the highest architectural, technical and landscaping standards. When Iberdrola planned to expand the electrical installation and build La Muela II, it was decided that the installations would be placed underground to avoid further impact on the area’s landscape. So, La Muela’s massif was bored through again to excavate a cavity “the size of Valencia cathedral,” according to Iberdrola engineers. This new cavern is so big it would be possible to build a 15-story apartment block of approximately 300 homes inside.

An 800-m-long, 45º shaft was excavated in which “steel pipes as high as a two-story building” were installed. The electrical company used a graphic image to illustrate the enormity of the dig: “If all the trucks used for excavating the rubble from the mountain were lined up end to end, they would stretch for 150 km.”

Project Details

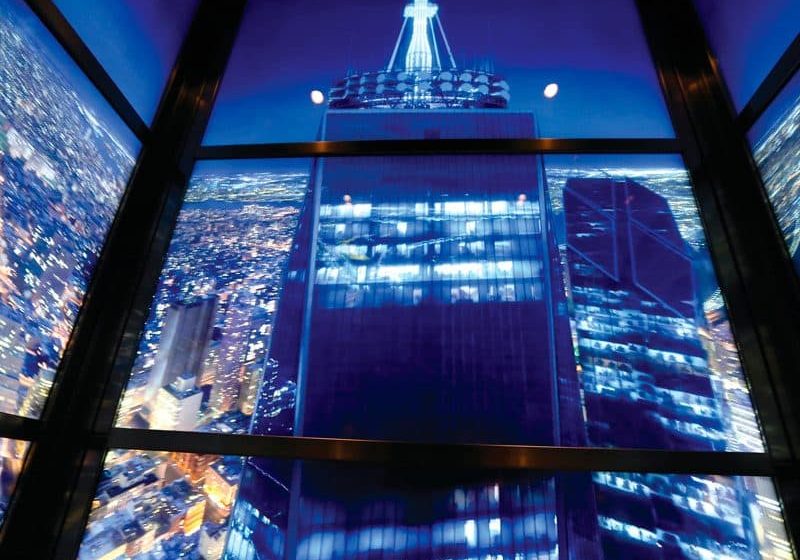

A ThyssenKrupp Elevadores hydraulic elevator and a sealed, waterproof elevator transport plant workers quickly among the various levels. The 2500-kg-capacity hydraulic elevator transports both materials and passengers for 12.6 m along three stops to the different heights of the generator turbines.

The electric traction elevator runs in a 182.8-m-long high-voltage cable shaft and links the secondary cavern with the surface, where the distribution of energy to the network begins. It travels at 1.6 mps along a span that includes five stops distributed along the shaft, which allow for proper maintenance of the installation. The completely sealed system — an essential characteristic of the installation — prevents its deterioration in a damp environment. The cabins were built using galvanized ribbed steel and protected with rubber barriers. All the push-button panels and lighting are sealed.

Where There’s a Will, There’s a Way

The assembly was one of the most complex ThyssenKrupp has undertaken. It used novel procedures to install the guides and the tensioning of the installation, since, along the full length of the site, materials could only be accessed at the highest and lowest points. The cable-shaft elevator installation required close consultation with Iberdrola on the overall design of a metallic structure that would permit correct assembly, guaranteeing comfort at the optimum speed.

Logistics were also key in the development of the project. Necessary materials were supplied by a store in Cortes de Pallás, thereby avoiding interference with other power-station activities and optimizing the cable shaft’s available space.

The team adapted its schedule to the client’s needs. The project had to be completed as quickly as possible, since the elevators were installed during the final phase of the power station’s construction — the perennially problematic phase of commissioning. Nevertheless, all the works were carried out safely. The companies met daily on site to look for ways that would allow for safer and more productive work.

The Project Management Department coordinated with the Special Assemblies department to see the project through with the highest quality standards demanded in a job of this caliber.

Credits

- Owner: Iberdrola Generación S.A.

- Operator: Iberdrola Generación S.A.

- Promoter: Iberdrola Generación S.A.

- Risk Prevention: AFJ Prevention

- Elevator Manufacturer: ThyssenKrupp Elevator Manufacturing Spain

- Vertical Transportation System Contractor: ThyssenKrupp Elevadores S.L.U.

Get more of Elevator World. Sign up for our free e-newsletter.