Landing Door Packages

Sep 1, 2020

New solutions for modernization and smokeproofing

by Lee Freeland

Munich, Germany-based MEILLER Aufzugtüren GmbH now offers the MOD Concept landing-door modernization kit used to replace all mechanical parts, while leaving the existing frame and sill unchanged. The process is an alternative to landing-door modernization, of which the company says, “Elevator constructors, as well as specialist planners and operators, have given. . . a wide berth.” It is usually a lengthy process with excessive material outlay, especially when the frame and sill are being replaced. Additionally, it often involves other tradespeople, which can make the process expensive and unpopular with building occupants.

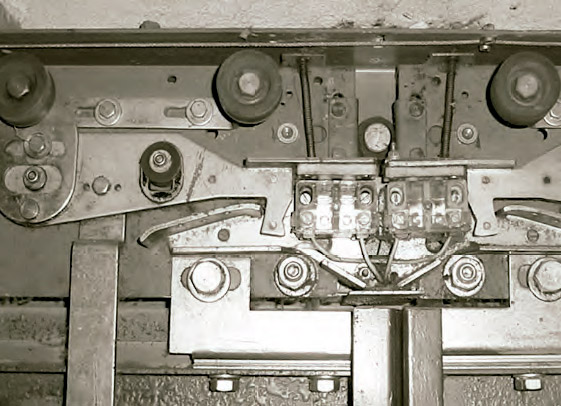

As existing landing door frames are often undamaged, the company explains, they can usually be visually renovated with less extensive work such as repainting, while this solution can be used to replace the mechanical parts for two- and four-panel telescopic and two-panel center-opening doors. In it, the existing transom is stripped of all mechanisms and electrical parts. The new MEILLER mechanical unit is then brought into the appropriate position (depth and height) in the transom. The door hangers are then connected to the existing door panels via adapter plates so the guides of the door panels run back into the existing sill. A new closing weight connection and the adaptation to the existing emergency release are included. The door panels can also be exchanged upon request, provided their thickness is 25-90 mm (in 5-mm increments). A new MEILLER car door is required for operation of the new hook bolts.

Next, the company now offers SmokeGuard®, a landing door with a smokeproof protective curtain designed to prevent smoke spreading between building stories in the event of a fire. The curtain unrolls in front of the landing door and shields the shaft from the landing when a fire is detected. “This gives the lift an effective smoke barrier that functions on each individual story,” Meiller explains. Citing the deadly 2017 Grenfell Tower fire in London, it emphasizes the importance of designing buildings so that they not only stop fire from propagating, but also protect against the spread of smoke.

While it is not truly possible to make smoke-resistant doors for lifts while still meeting applicable codes, MEILLER says, the lift should be sealed off floor by floor. It sees combining the door with a smokeproof product as the only way of achieving a smoke seal for a landing door. This solution also leaves door fire certification unaffected. The door portion of SmokeGuard undergoes fire testing in accordance with EN 81-58.

Once EvoN (niche installation), a frame width of 100 mm and other conditions are satisfied, MEILLER can prepare the door frame as required for the smoke-curtain installation. This component is installed on the frame of the landing door at the construction site. The retractor box is mounted on the upper frame element along the entire width of the door. Guide rails, enclosed on three sides, are placed over the side sections of the frame. The box and rails can be supplied in stainless steel (K240 brushed or with linen pattern) or in RAL powder-coated metal. A universal controller (such as a static or dynamic fire-control system or fire-alarm center) works in conjunction with the lift controller to activate the curtain.

Retrofitting the product is feasible, but the upper frame must be at least 210 mm tall, while the side frame sections require a minimum clearance of 100 mm for accommodation of the runner rails.

Get more of Elevator World. Sign up for our free e-newsletter.