A smart modernization far outperforms complete replacement in both economic and environmental aspects.

by Michael Pyper

The increasingly evident climate crisis has highlighted the end of throwaway culture; modernization is the order of the day. This principle also holds true for hydraulic elevator systems. These systems can be upgraded step by step to meet the latest technological standards and at significantly lower costs compared to a complete replacement.

Tony Aschwanden, product and application manager for Bucher Hydraulics, said:

Aschwanden

“Complete renewal of an existing elevator system unnecessarily uses resources like scarce raw materials and places a burden on the environment through processing and transportation. Moreover, a significant amount of what is termed ‘gray energy’ goes into complete renewal, a fact that is often overlooked.”

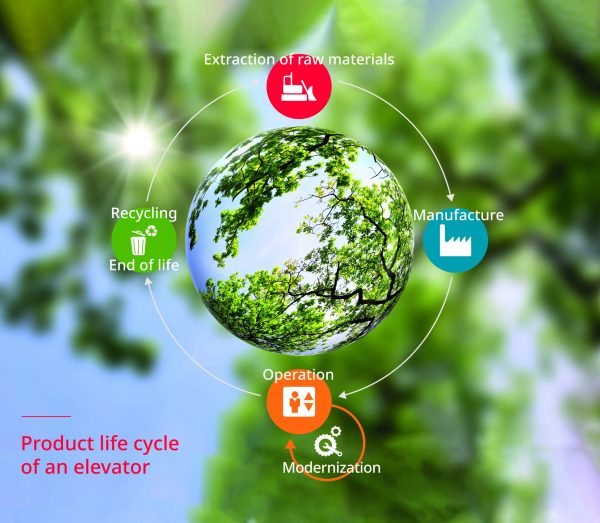

And he should know. Aschwanden has been with Bucher Hydraulics AG in Neuheim, in the Swiss canton of Zug, for over 16 years. Gray energy encompasses the total energy required for all processes preceding and following the operation of a product, including manufacturing, transportation, storage, sales and disposal. This includes precursor products all the way to raw material extraction and the energy expenditure in production processes. Aschwanden said, “To achieve the latest technological and safety standards, it is entirely sufficient to replace just parts of the elevator or relevant components.”

Enhanced travel comfort, higher safety standards, improved energy efficiency, digital connectivity and, hence, monitoring, along with resource conservation, represent additional positive factors. Bucher Hydraulics not only provides all necessary drive components for the optimal and contemporary modernization of passenger and freight elevators but also know-how and advice. This is crucial for project success as operating conditions can vary significantly. For instance, an elevator in a residential building will face considerably lower requirements than one in constant operation in a shopping center.

Incremental Investment Achieves the Same Goal

Aschwanden highlights a crucial aspect in terms of economic sustainability: “Modernization can be carried out in stages over several years to spread the costs.” Conversely, a complete replacement must be done all at once and restricts access to crucial parts of the building for an extended period.

Another factor in favor of modernization is the widely differing lifespan of elevator components. A building envelope has an approximate lifespan of 80 years. While rails and cylinders can reach this age with proper maintenance, the lifespan of elevator components, such as the drive or control system, is considerably shorter. A gradual modernization allows for component replacement as needed. The hydraulic drive, for example, needs to be modernized approximately every 30 years, the elevator control every 20 years and the doors and cabin every 15 to 20 years. Aschwanden adds:

“The production of an elevator system has a significantly larger impact on the environmental footprint than its total time in operation, which is why a complete replacement is far less sustainable than a modernization.”

Modernization Within Existing Structures

Modernization vs. new construction: The environmental footprint of modernization is significantly smaller than that of complete replacement.

Even in the modernization of existing buildings that have not had elevator systems, hydraulic elevators offer significant advantages. The space-saving and flexible design often presents a solution for retrofitting, thereby enhancing the value of established structures. A hydraulic elevator requires, on average, 12% less shaft space than a cable-driven elevator, as it does not need a counterweight. In the case of “backpack” elevators, a single load-bearing wall is sufficient and allows for door openings in three directions. Consequently, the streamlined hydraulic elevators can be retrofitted in spaces like stairwells or inner courtyards.

The forces involved act directly on the foundation, which is beneficial in terms of structural integrity. The guide rails can be designed smaller and, if necessary, invisibly integrated into the cylinder. The existing structural integrity of the building remains unaffected. Hydraulic elevators are, therefore, highly suitable for buildings without shafts. They are also the right choice for buildings that may have extra floors added later.

Customized Energy Savings

A frequently cited drawback of hydraulic elevators compared to cable-driven ones is their higher energy consumption during operation. However, technology has taken a significant leap forward thanks to variable-speed drives. Traditional hydraulic pumps always run at full speed. The travel curve — encompassing acceleration, cruising and deceleration — is controlled by a valve. Excess oil is returned to the tank in an energy-inefficient manner leading to unnecessary heating. This may even necessitate the use of an oil cooler. Here, energy is needlessly wasted.

Variable-speed drives, on the other hand, control pumps from zero speed. This ensures that the pump delivers only what is required for the ideal travel curve. With energy savings of 25-30%, the additional cost of the variable-speed drive is rapidly recouped, particularly for heavily used elevators.

New technologies take energy savings a step further. Supercapacitors, also known as supercaps, can be charged and discharged much faster than batteries. Moreover, they last for far more charging cycles. Aschwanden noted, “We have made this technology available for elevators and can even retrofit it — with the appropriate software adjustments — to existing units.”

The principle involves the oil displaced by the cylinder during descent driving the pump. The pump then turns the motor, which functions as a generator, producing and storing electrical energy. This stored energy is then available for the next ascent, reducing power draw from the grid. This yields an additional 20-30% energy savings, which is especially beneficial for heavily used installations.

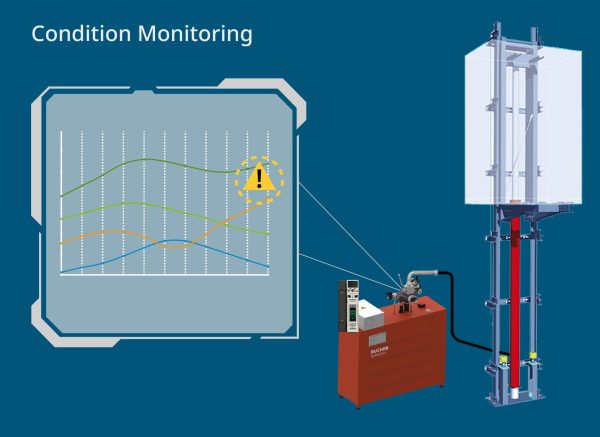

Condition monitoring: iValve, the electronically controlled lift control valve from Bucher Hydraulics, along with the iCon-2 controller, provides data for predictive maintenance.

The Case for Modernization

Compliance with current standards ensures increased safety.

Performance is adapted to meet current needs.

Enhanced travel comfort

Energy-efficient drive technology (consumption is lower than previously)

Guaranteed availability of spare parts

About Bucher Hydraulics

Bucher Hydraulics is a globally leading provider of innovative hydraulic drive and control technology for mobile and stationary applications. With production facilities and sales offices worldwide, its target industries encompass construction machinery, materials handling and lifting equipment, municipal services technology, renewable energy, agricultural machinery, mechanical engineering and elevator technology.

Elevator manufacturers worldwide, ranging from global players to medium-sized enterprises, utilize these hydraulic elevator components. Valves, power units and cylinders are found in both passenger and freight elevators. They enable lifting heights exceeding 25 m and payloads of over 40 T. Their flexibility provides architects with ample room for modernizing existing systems. Machine-room-less (MRL) hydraulic systems require minimal space and meet the highest design standards. Low maintenance needs, high energy efficiency and durability result in a favorable cost-benefit ratio. Lastly, passengers greatly appreciate the improved level of travel comfort.

iValve: A New Era in Elevator Hydraulics

Bucher Hydraulics is a member of the VDMA BlueCompetence initiative and is committed, under the ECOdraulics name, to developing and manufacturing particularly energy-efficient, low-emission, durable, lightweight and space-saving products. One such product is the intelligent hydraulic valve iValve.

Self-optimizing: The iValve from Bucher Hydraulics is an electronically controlled lift control valve for hydraulic elevator systems, also suitable for swiftly replacing conventional valves.

Equipped with sensors and corresponding software, it is self-learning and self-optimizing. iValve can be installed in just 60 min and saves up to 30% of energy in operation. It also offers extensive networking capabilities. Its modular design enables numerous retrofit options. Very responsive closed-loop control ensures excellent travel quality and excellent stopping accuracy in both directions, regardless of oil temperature and viscosity. The “smart” feature includes predictive maintenance, allowing proactive response before any damage occurs.

Modernization is made even simpler with the MULTIkit, containing all the components needed for modernizing a hydraulic elevator without the need to replace the elevator control system. This allows a mechanical valve to be replaced with the latest iValve generation in just one day. As Aschwanden explains, this is mainly achieved through a pre-defined retrofit package, which includes factory-set system data. His conclusion:

“With elevator components from Bucher Hydraulics, the gradual modernization of elevator systems is consistently superior to complete replacement, both in terms of investment and environmental footprint.”

Michael Pyper is a freelance writer for Bucher Hydraulics.

Get more of Elevator World. Sign up for our free e-newsletter.