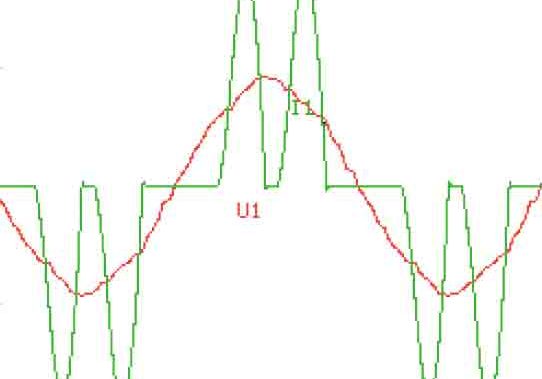

Dekra e.V. of Stuttgart, Germany, recently launched a product for objectively assessing the safety, ride performance and quality of lifts. The Likos laser-measuring system delivers key information about the condition of a lift in minutes. The device (with case) weighs 10 kg and can be quickly installed in the shaft pit. Dekra designed the system for testing lifts, as well as for commissioning and diagnostic purposes. In standard testing, the device records parameters at a rate of 1,000 measuring points per s. and delivers key data that more than satisfies test-relevant specifications.

- The system provides the following: More time to inspect the lift facility and rectify minor defects during testing

- A quieter atmosphere in a hazardous working environment

- Minimal stress on the lift facility

- because just one measurement run is required

- Shorter lift outages

Likos allows the user to calculate the optimum ride cycle. The measurement also records data on ride comfort, smooth door action and capacity utilization. Dekra plans for the future possibility of using the system to automatically create a comprehensive ex-pert report for lifts. To this end, mini recorders that simultaneously record additional physical variables such as current consumption to determine the energy consumption of individual components, user behavior, as well as the condition of components would be installed at various points within a facility.

For more information, contact Dekra at Handwerkstrasse 15, 70565 Stuttgart, Germany; phone: (49) 711-7861-2122; fax: (49) 711-7861-2700; e-mail: Tilman. [email protected]; or web-site: www.dekra.com.

Magnalight Permanent-Mount Led Beacon

Magnalight by Larson Electronics LLC has announced the release of an LED beacon light designed for permanent mounting. The Magnalight SL4-A-LED Strobe Beacon can be set to operate as a strobe or steady burning marker and provides visibility through the use of four 3-W LEDs. The beacon is intended for work, security or utility operations, or anywhere else a powerful strobe is required.

The product is a compact signal beacon that weighs 1 lb. and houses its LEDs within a waterproof and shock-resistant housing. It draws 12 W and less than 1/4 amp. A specially designed lens allows the light from the LEDs to be radiated 360°; therefore, the beacons can be mounted on both the sides and tops of vehicles, equipment and machinery. They can be switched between a strobe or steady burn mode by toggling a user-supplied inline power switch. The product is designed as a permanently mounted lighting solution and avail-able in white, amber and red.

For more information, contact Larson Electronics at 9419 East U.S. Highway 175, Kemp, Texas 75143; toll free: (800) 369-6671; phone:(903) 498-3363; fax: (903) 498-3364; or e-mail: [email protected].

New Products From Wachendorff

Wachendorff Automation GmbH & Co. KG presented three new products at Interlift 2011 in October. First, the motor feedback WDGF is precision designed with dynamic motion control in mind. The product provides accurate signals for the quick control of synchronous motors, even under extreme environmental conditions. Its optical principle is intended to guarantee fast and accurate measurement of position and speed, while a rugged design is for operational stability.

Silent Move Twin provides digital shaft copying and is designed with two independently functioning encoders. The premounted measuring unit can be installed in 20-45 min. and is able to utilize any combination of absolute and incremental encoders in the circumferential system. It was developed for speeds up to 4 mps, with a maximum height of 60 m and acceleration of 2 mps2. Its rounded belt teeth ensure smoothness. Belt guiding is equipped with a safety function – the release of energy for the positive opening of the safety switch in the event of tearing results solely from the weight force. A lever principle enhances safety.

With CANopen Lift, Wachendorff extends the product range of its established Silent Move line. All system types – circumferential or guided systems with toothed or nubbed belts, premounted measuring unit or complete measuring system – can be equipped with the WDGA CANopen Lift absolute encoder series. The se-ries utilizes field-proven multiturn EnDra® technology, which operates without barriers or gearboxes. The encoders function free of wear and maintenance, increasing operational lifetime.

For more information, contact Wachendorff at Industriestrasse 7, D-65366, Geisenheim, Germany; phone:(49) 6722-996525; fax: (49) 6722-996570; e-mail: [email protected]; or website: www.wachendorffautomation.com.

Electrolock Door Restrictor

Electrodyn Systems’ ElectroLock is an electronic door restrictor that locks the elevator car door when it is within the locking zone (3 in. above and below the landings). The product prevents entrapped elevator passengers from escaping a suspended elevator car without emergency rescue personnel. Escaping an elevator when it is stuck between landings has resulted in serious injury and sometimes death; safety codes to prevent this from happening are being enforced.

Electronic door restrictors can generally be fitted to most door op-erators with a minimum of labor, making them an attractive alternative to the mechanical type. The noise and clearance issues associated with mechanical restrictors are generally nonexistent, but electronic door restrictors that use photoelectric sensors can be problematic, since calibrating the electric eyes and target strips they use is time consuming and their initiation can be degraded in the presence of dust, smoke, grime and ambient light.

The ElectroLock retains electronic door restrictors’ benefits, while eliminating their downfalls by using radio-frequency-identification technology for its landing sensing. Additionally, it does not rely on a battery backup to maintain functionality during a power loss. The product uses bi-stable solenoid technology to maintain bolt position after initiation. Though many electronic restrictors rely on battery power for functionality, there is talk of upcoming code changes to require them to be upgraded or replaced by the local enforcement bodies in the interest of passenger safety.

For more information, contact Electrodyn at 4100 North Powerline Road, Suite 1-2, Pompano Beach, Florida 33073; toll free: (800) 447-5442; fax: (954) 933-4185; or website: www.electrodyn.com.

Kleenrite 2240 Escalator Cleaner

Kleenrite Manufacturing has introduced its 2240 Escalator and Moving Walk Cleaner, which fits all equipment sizes and does not require an operator. The 2240 features 21-in. heads capable of being adjusted up to 40 in.; a 1-gal., 35-psi spotting tank; two maintenance cleaning brushes; two restorative cleaning brushes; a built-in qt. spray-bottle holder; dual filter bags; a 25-ft. power cord; adjustable restraint arms; four wheels for easy transportation; a compact design; and a flat back with molded glides for easy loading.

For more information, contact Kleenrite at 1122 Maple Street, Madera, California 93637; toll free:(800) 241-4865; phone: (559) 673-5700; fax: (559) 673-5725; or website: www.kleenritemfg.com.

Digipara Software Updates

At Interlift 2011 held in October in Augsburg, Germany, DigiPara GmbH re-leased an enhanced version of its Liftdesigner and Escalatordesigner software featuring new 3D export formats. The updated software can now save 3D elevator and escalator drawings in SAT or STEP formats, which can be imported into other 3D computer-aided design (CAD) programs such as Au-todesk Inventor or SolidWorks, enhancing the customization and design process for manufacturers. In addition, elevator and escalator manufacturers can send 3D models created by the programs to builders and architects, which can then be integrated into 3D architecture software such as Autodesk Revit and Archi-CAD. This allows architects to more precisely display and perform interference checks between elevators, escalators and the building.

For more information, contact DigiPara at Augustinusstrabe 11D, 50226 Frenchen, Germany; phone: (49) 2234-999-448-23; or website: www.digipara.com.

Vision Series From Formula Systems

Formula Systems launched its new Vision series at Interlift 2011, held October 18-21 in Augsburg, Germany. Suitable for modernization and new-equipment applications, Vision products are available in a range of profile sizes and feature options, all offering 2D offset beam technology.

The new Sill Light feature has been designed to reduce the potential for tripping hazards by utilizing a high-contrast light to draw passenger attention to the floor sill zone. In addition, a beam path locator consists of an array of amber LED warning lights.

These lights provide a visual indication of the 2D beam path locations, assuring passengers and operators of system functionality. Adapt 3 is a 3D adaptive traffic-detection system. The technology detects people and objects as they approach elevator doors, holding them open to minimize the chance of personal injury or door damage.

For more information, contact Formula Systems at Technology House, Oakfield Estate, Eynsham, Oxford, OX29 4AQ, U.K.; phone: (44) 0-1865-882442; fax: (44) 0-1865-881647; or website: www.formulasystems.com.

Get more of Elevator World. Sign up for our free e-newsletter.