Load Weighing Using Suspension Wire Rope Sensors

Jul 1, 2012

Reasons why load weighing should be installed on all elevators are explained.

Load weighing for an elevator application is best described as the process of measuring the load in the cab, communicating that measurement to the elevator controller and interpreting the load at the elevator controller, all of which are important functions for all elevators. Whether the process takes place for a three-stop hydraulic elevator or a high-speed traction elevator, the purpose and requirements are similar.

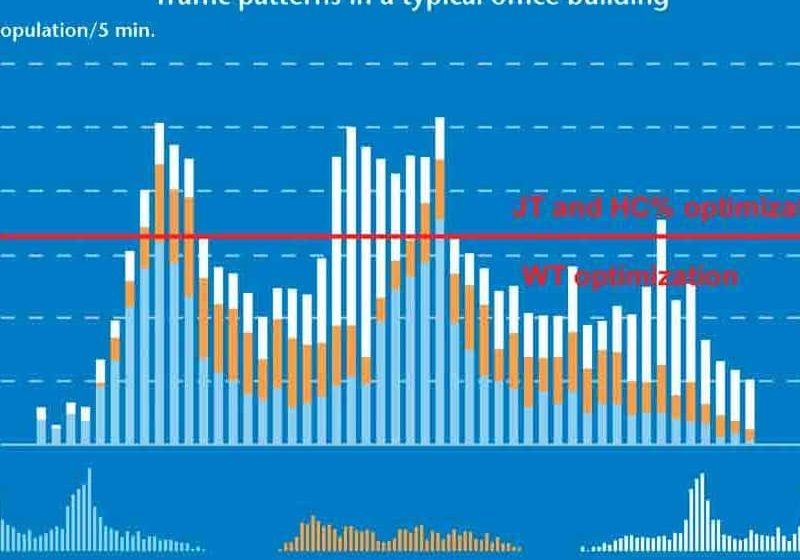

There are three major reasons why load weighing should be installed on all elevators. The first and major one is the safety of the passengers. All elevators are rated by capacity and speed. If you exceed the capacity of the elevator, the safety of the passengers is compromised and in jeopardy. The second is improved operation and efficiency of the elevator. By providing accurate load information to the elevator controller, certain elevator functions can be programmed to ensure the most efficient operation of the elevator and maximize passenger traffic. For instance, if the cab is fully loaded, the elevator controller should ignore or bypass all hall calls until there is room to accept additional passengers. Conversely, if the cab is empty, it is best the elevator controller ignores all car calls.

The final reason is related to the first two reasons. Proper load weighing protects and extends the life of the elevator equipment. Exceeding the capacity of the elevator can affect the elevator in that it may need additional maintenance. Not utilizing the elevator to its maximum design capabilities, in terms of the number of passengers in a given number of travels for a given hoistway, will affect the end user in higher maintenance costs per passenger and disgruntled passengers continually awaiting car arrival.

How to Measure the Load in the Elevator Cab

The easiest method to measure the load in the elevator cab is to situate a sensor in the elevator system to determine the load and communicate its data to the elevator controller. Several sensors for that purpose, which can be located in various locations within the hoistway, are available. One of the most popular and logical locations for traction elevators is on the elevator ropes. Here, the sensors measure the load imposed on the ropes as more people or material enters the cab. A sensor is attached to each suspension rope to ensure the full load in the cab is measured and eliminate any differences between ropes due to uneven tension.

This type of sensor can be used on new or existing applications, as well as modernizations. The rope configuration should not affect the installation, which should be simple and quick. The sensors are easily attached to the ropes, while the connection from the sensors to the controller is a five-wire or USB plug-in connection (Figures 1 and 2). In addition, there are some controls that, while measuring the load in the cab, can also measure the tension of the individual ropes. This information can be displayed on the control provided with the sensors, enabling the mechanic to accurately tension each rope, thereby extending rope and sheave life.

Once the sensors are in place on the ropes to measure the load in an elevator, the sensors have to be connected to a controller that can accept the electronic signal the sensors provide. In turn, the load-weighing controller will then provide usable signals the elevator controller can use to prevent overloading the elevator and maximize elevator operation and efficiency. The most reliable controllers today for this purpose are microprocessor-based, digital ones that are easy to program and interface with the elevator controller. Most load-weighing controllers provide relays that change state at application-specific, programmed load levels, and some can provide variable outputs or other communication methods (0-10 VDC, 4-20 mA, RS-485) directly proportional to the load in the cab (Figure 3). While most of these controllers can be calibrated without using weights, they are most accurate when calibrated with weights placed in the cab.

The details of how and what to connect to the elevator controller to use the information gathered by the load-weighing controller is application and controller specific. But, in simple and general terms, a few options are:

- For safety purposes, the load-weighing controller can be programmed to provide a contact closure or opening when 110% of capacity in the elevator is measured. This relay, in turn, can be used by the elevator controller to keep the doors open and prevent the cab from leaving the floor until people exit the cab, thus decreasing the load to a safe level.

- For efficiency purposes, the load-weighing controller can be programmed to provide a contact closure or opening when full-load capacity in the elevator is measured. This relay, in turn, can be used by the elevator controller to ignore all hall calls, since the cab would be at capacity and could not safely accept any more passengers.

- The load-weighing controller could also be programmed to provide a contact closure or opening when a very small load in the elevator is measured. This relay, in turn, can be used by the elevator controller to ignore all calls from inside the cab, since it is unlikely a person would be in the cab. It could be assumed the calls would be a result of someone exiting the cab after pressing several floor buttons.

- Operationally, the variable load output of the load controller (0-10 VDC or 4-20 mA) can be used as a signal to determine the pre-torque level of the traction-elevator motor. This will ensure a comfortable and smooth start from every floor without rollback.

- For maintenance purposes, controllers that measure the tension on each rope can be programmed to send a signal to the elevator controller or remote elevator monitoring system when any rope is greater than a predetermined tension range. This can trigger maintenance personnel to re-tension the ropes to extend rope and sheave life.

While load weighing is not a new idea, the technology to meet the design needs of the elevator and the safety of the passengers is improving to ensure these objectives are met easily and accurately. This solution for suspension elevators works well to that end with proper understanding of what the elevator application requires and can electromechanically accept.

Get more of Elevator World. Sign up for our free e-newsletter.