Required in new installations, door lock monitoring remains under-implemented for existing elevators in the U.S.

by Kevin Brinkman and Philip W. Grone

When a passenger steps into an elevator and the door closes, little thought is given to how the door is secured. Based on experience, one takes for granted that the doors will close and remain secure until the destination is reached. The confidence in the safety of the elevator doors, through which millions of people pass each day, rests on the fundamental technology of door lock monitoring (DLM). This important feature has been required on new elevators since 1996; however, there remain significant gaps in its deployment on elevators installed to earlier editions of the elevator code.

DLM protects the riding public and the industry workforce against the risk of a defect in elevator doors. DLM is a function of the elevator control system that monitors the door’s closed and locked circuits to ensure the contacts switch from closed to open when the door is cycled at a landing. If the contacts do not switch, it can indicate that one is defective or shorted, bypassing the door safety circuit. When a fault is detected, the elevator controller prevents the car from moving. Faults can be caused by several conditions, including a failed car or hoistway door contact or by a jumper used for troubleshooting that has been inadvertently left in place.

Put simply, DLM keeps the elevator from leaving a landing unless the doors are completely closed and locked.

Modern Code Requirements Are Clear — the Roadmap Is Confusing

As noted above, DLM has been a code requirement for new elevator installations throughout North America for nearly 30 years. In 1996, the American Society of Mechanical Engineers (ASME) incorporated DLM requirements in ASME A17.1, the Safety Code for Elevators and Escalators, to harmonize standards in the U.S. with those already adopted by the Canadian Standards Association (CSA).

However, for existing elevators installed prior to DLM requirement for new installations, the regulatory environment is fractured and confused. ASME A17.3, the Safety Code for Existing Elevators and Escalators, did not include DLM requirements for existing electric traction elevators until 2015. Due to an administrative issue, hydraulic elevators were not added until the 2017 edition.

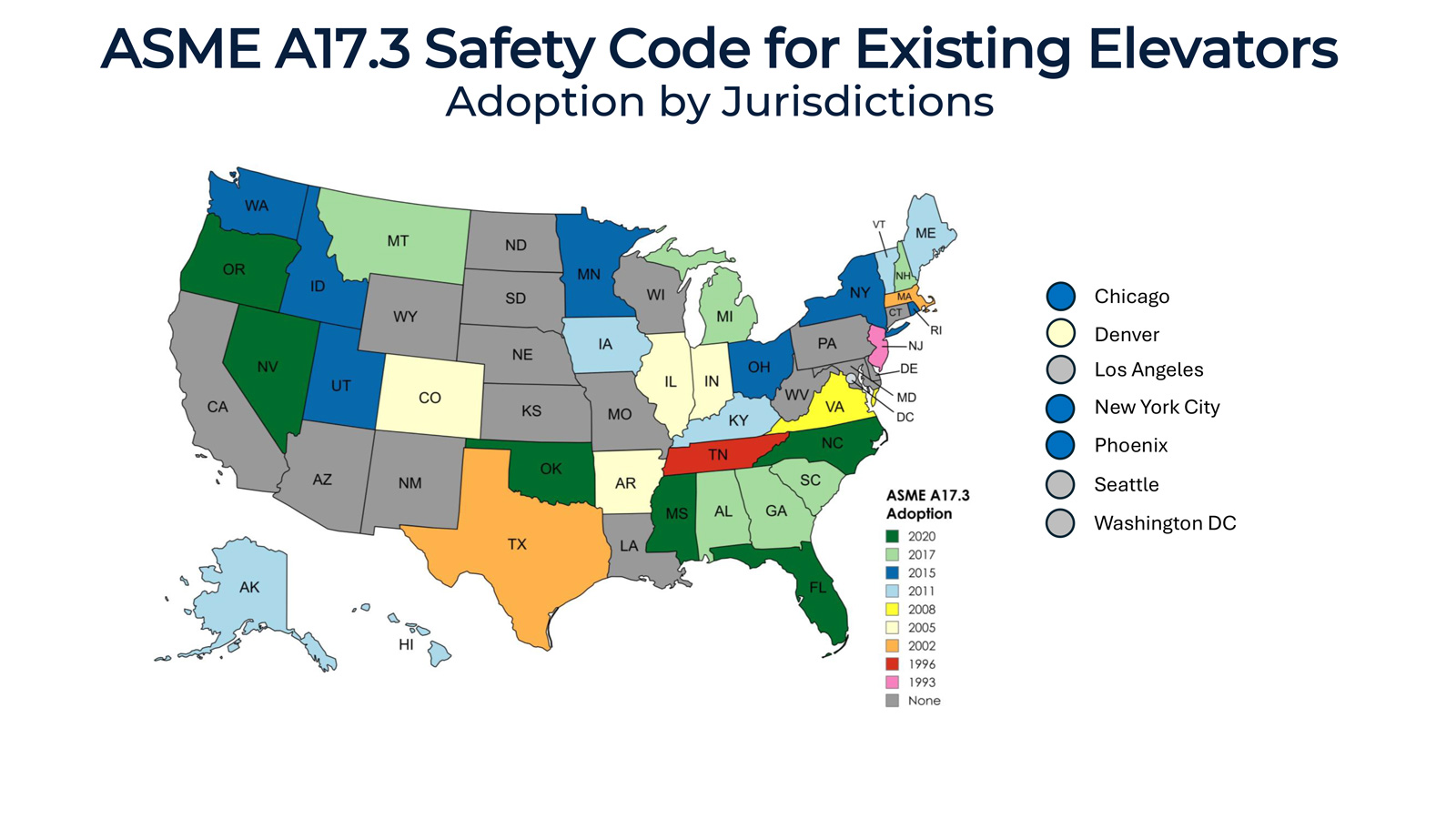

The pace of adoption of ASME A17.3 is also a complicating factor, as indicated by the accompanying map. ASME A17.3 adoption lags behind ASME A17.1/CSA B44. Over the last five years and emerging from the COVID pandemic, AHJs have made significant progress in updating their elevator codes for new installations to more current editions of ASME A17.1.

However, for existing elevators:

- 16 states and the District of Columbia have not adopted ASME A17.3 at all;

- 15 states are using earlier editions of the code that do not include DLM; and

- 19 states are on an edition of ASME A17.3 that includes DLM, but seven of the 19 are not enforcing DLM on hydraulic elevators.

- In localities managing their own elevator programs, the environment is similarly inconsistent.

The stark differences in ASME A17.3 adoption and the lagging adoption of more modern codes suggest a confusing landscape for the industry, building owners and operators and the riding public for the near future. But there are signs of progress amid a renewed emphasis by AHJs on improving standards for existing elevators.

The Challenge of Catching Up and Signs of Progress

For many jurisdictions, the costs of upgrading existing equipment and the timeline within which work must be completed have been impediments to adoption and to keeping the code current. Recently, AHJs have begun to recognize the need to move forward with safety upgrades on older equipment and have worked with affected stakeholders and the industry to develop new implementation approaches. While these approaches vary, they have all been informed by the safety policy, oversight and enforcement objectives of the AHJs, the concerns of building owners and operators, supply chain and other industry dynamics and the compelling benefits for the riding public and the industry workforce in enhancing the safety of equipment. The results are positive, as important safety requirements are being advanced throughout the country.

To cite some prominent examples:

- Last year, Nevada completed a re-adoption of ASME A17.3, initially undertaken by emergency order during the COVID-19 pandemic. Nevada provided for a phase-in for safety upgrades related to door restrictors and DLM by 2025 and ascending car overspeed by 2027.

- Michigan elected in 2023 to add ASME A17.3 to its elevator code and phased-in 28 distinct provisions on varying schedules over a five-year period.

- Oregon provided this year for a six-month transition period to the 2020 edition — upgrading one of the five oldest adopted ASME A17.3 codes in the U.S.

These tailored and balanced initiatives by AHJs address the need to upgrade codes but also provide the time needed by all stakeholders to plan, budget and execute the upgrades to older existing equipment. The industry has learned a great deal from these discussions.

The National Elevator Industry, Inc. (NEII) and its member companies are working on recommendations for the ASME process to improve ASME A17.3 both from a substantive and implementation perspective. The industry will continue to work with AHJs to find reasonable solutions for effective implementation and enforcement that can provide a pathway to further adoption of ASME A17.3 to enhance the safety of the riding public and the industry workforce. The door is always open to ideas that will lock in everyone’s interest in the safest building transportation options available.

Go to NEII to learn more about how NEII is impacting elevator safety.

About the Authors

Kevin Brinkman is the senior director of Codes at the National Elevator Industry, Inc. (NEII). He has more than 32 years of elevator and lift industry experience, previously serving as vice president of engineering for ThyssenKrupp Access and National Wheel-O-Vator, as well as serving as an elevator consultant. Brinkman joined NEII in 2015, focusing on code development and adoption along with the safety of elevator workers and the riding public. He serves on several influential code development committees in his position and is a member of the ASME A17 Standards Committee for the Safety Code for Elevators and Escalators. Brinkman serves as chair of the ASME A17 Editorial committee. He also serves on the International Code Council/ANSI A117.1 Committee, National Fire Protection Association 5000 and 101 technical committees, and is involved in the International Building Code process.

Philip W. Grone joined NEII as vice president for government affairs in January 2021. He has also held positions as a consultant, a director in the public sector practice of the internet business solutions group at Cisco Systems and as deputy under secretary of defense for installations and environment.

Get more of Elevator World. Sign up for our free e-newsletter.