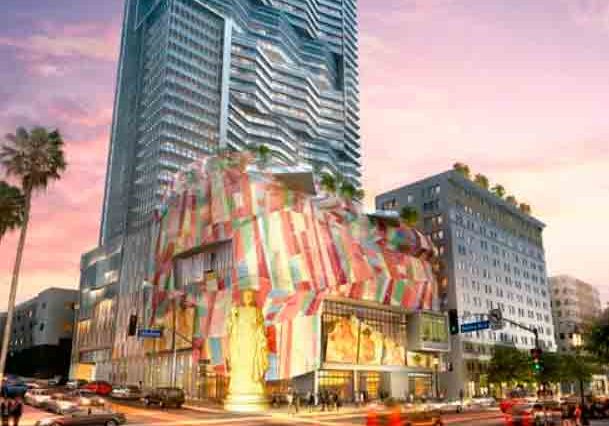

Lotte World Tower Seoul, South Korea

Jan 1, 2018

One-of-a-kind, record-breaking installation is an engineering and artistic marvel.

submitted by Evelyne Lee, Otis Elevator Korea

written by Hunil Kim, Otis Elevator Korea

Since Elisha Graves Otis invented the first safety elevator more than 160 years ago, Otis has evolved to include passenger, freight and service units, and progressed from wooden interiors to all-glass cabs — and almost anything else necessary to meet a customer’s needs.

Otis Elevator Korea added to this evolution in 2017 with the installation of the world’s longest double-deck elevator in the Lotte World Tower in Seoul. The total installation includes 30 elevators — 11 SkyRise® units (including two double-deck elevators) and 19 Gen2® elevators, along with 19 escalators, in the country’s tallest vertical structure at 555 m.

Sky Shuttle, the double-deck elevator, runs 496 m from the second basement to the building’s observation deck, Seoul Sky, on the 121st floor. Using a single hoistway, it can carry 54 passengers to the top in 1 min. The installation includes four 100-T traction machines — the first of their kind in South Korea — to power the elevators.

“Double deck” refers to an elevator with two cabins, one placed on top of another, traveling in a single shaft for increased transport capacity. It comes as no surprise that Otis took on the Lotte World Tower challenge, given its long history of providing double-deck elevators, having installed the world’s first at the City Services Building in New York City in 1931.

Guinness World Records Recognition

Lotte World Tower’s double-deck elevators travel not only farther than any other elevator in the world, but also faster. As a result, in January 2017, the building was recognized by Guinness World Records for having the longest traveling and fastest (with the largest load) double-deck elevators in the world. The Sky Shuttle takes passengers literally to the sky at a speed of 10 mps, or 600 mpm. In addition, the double-deck system transports more passengers simultaneously than any other elevator. The cutting-edge elevators ensure visitors do not lose much time waiting, instead reaching their destinations as quickly and efficiently as possible.

As if the double-deck elevators themselves weren’t enough, Lotte wanted the units to provide a truly special customer experience. Passengers experience virtual reality (VR) inside the elevators as they move to the observation deck. Created by LG Electronics, 60, 55-inch organic LED (OLED) screens cover the entire elevator interior surface, including the ceiling, excluding only the doors. Otis provided software to precisely synchronize the OLED signage’s digital content with the elevator controls. Seoul Sky was recently recognized for its VR work in the elevators at Lotte World Tower with the prestigious Red Dot Design Award.

A VR Look at Seoul

While passengers can’t see Seoul’s cityscape as the elevator travels at the center of the structure, Seoul Sky provides them with a beautiful visual display of Seoul’s history and its landmarks — from Gyeongbok Palace and the National Assembly building to Jamsil Stadium and, of course, the Lotte World Tower itself.

As visitors immerse themselves in this dynamic experience, the trip to the observation deck may seem all too fleeting. The screens are flawlessly synced with the elevator controls, offering a variety of entertainment. The screens can also be programmed to display specific advertisements when the elevator stops at the tower’s duty-free shops on floors eight and nine, a complicated and challenging technical achievement that Otis engineers made possible.

Transportation System

While what a passenger sees in the Lotte World Tower’s double-deck elevator cabs is impressive, technology nerds are even more taken by the machinery involved to make the elevators perform flawlessly.

To bear the elevator’s speed, weight and traveling distance, Otis used cables that weigh more than 10 T, as well as traction machines specially designed to stand the weight of 100 T each. To install the two double-deck passenger elevators, as well as two other, single-deck elevators for emergency use, Otis needed to lift and place four 100-T traction machines (with a machine weight of 21.6 T each) in the machine room at the top of the skyscraper.

Ordinarily, buildings have a flat top, and the top is still open when an elevator traction machine is lifted and placed directly into the machine room, since construction is still incomplete at that point. Lotte World Tower was a different story. The top of this majestic skyscraper resembles a spire split into two, which created a challenge for machine-room placement.

Steel frames at the top of the tower were in place when the traction machines were to be installed, and it was critical that the traction machines were lifted and placed in the machine room without damaging the two spires under construction. In addition, without a solution to achieve this task, there was risk to the scheduled deadline.

In the past, Otis has lifted and installed 70-T traction machines at the Northeast Asia Trade Tower in Incheon (the tallest building in South Korea at the time) and at the International Finance Center Seoul. That said, both buildings also had their machine rooms at the top, where the traction machines could be placed directly. Both featured flat roofs that were open during traction-machine installation. Neither building presented the challenges the Lotte World Tower posed.

Teamwork Solves Unique Challenge

As a result, Otis tapped into its global network to bring together talented minds and benchmark best practices. The Otis team discussed ideas with Lotte Engineering & Construction (E&C) for the optimal solution. A plan was carefully drawn up, with details on every move of lifting and placing the machinery.

First, the traction machines were lifted from the ground to a selected spot on the 124th floor. Once inside, the next step was about moving the machines to their correct position in the machine room safely and precisely. Since the spot where the machines were to be located was 2-5 m above floor level, they were moved laterally using bogies (a modular assembly of a chassis with wheels and axles) and placed next to the spot where they needed to be lifted into place.

Then, using four automatic chain blocks installed in the machine-room ceiling, the machines were raised from the floor and placed in their correct positions on top of beams and sleeves to guarantee precise placement. To ensure that all four traction machines were safely hoisted to the top, Otis repeatedly conducted dry runs in cooperation with Lotte E&C. Practice made perfect, as there wasn’t a single safety incident during the installation, which was completed on time.

In skyscrapers, the key is to keep up elevator installation with the frame construction, growing taller and higher together. With this in mind, Otis worked with Lotte E&C to adopt a modular approach, installing the shaft in different modular segments. Otis had previously implemented this method at Burj Khalifa in Dubai and the Shanghai World Financial Center, which both provided valuable lessons that helped ensure the Lotte World Tower elevator project would be successful.

In this approach, a temporary machine room was installed midway in a long shaft to make the process safer. The method also allowed interior work to be done beforehand in the elevator hall, a crucial element in enhancing the efficiency of the entire work process.

Otis used a multi-modular installation approach for the first time in South Korea. First, it installed a temporary machine room after the primary frame construction was completed, then built the entrance and guide rail all the way to the bottom floor, followed by the rest of the steps. This was in line with the building’s construction. Compared with other assembly methods, this multi-modular approach reduced elevator installation and construction time by two-and-a-half times, ensuring building construction schedules were met.

A Cutting-Edge Building-Sway System

It’s common that buildings 100 stories or more sway in high winds or an earthquake. Given that the Lotte World Tower has 123 stories, the double-deck elevators going to the observation deck utilized a cutting-edge building-sway system customized to withstand the effects of the natural phenomenon, while ensuring maximum safety. The system features internal sensors that detect the extent of sway in high winds or earthquakes and determines whether to slow the elevators or evacuate passengers to the nearest “safe” floor.

In its initial design, Otis created a massive pendulum, tailored to the elevator weight, location within the hoistway and speed to detect the building’s sway. In addition, the tower’s elevators are designed to operate and travel normally between “safe” floors unaffected by the sway. For example, when the top floors sway, elevators can continue to operate and travel to and from lower levels that do not sway. The extent to which the pendulum sways is divided into three levels, by which the elevators are controlled, slowed or stopped. The standards for each level differ by project. For the Lotte World Tower, they were configured in line with the building sway detected in the worst typhoon and strongest winds in the last century.

Because the pendulum helps detect building sway and controls the elevators, Otis was able to come up with an even more meticulous analysis and immediate response. The approach used in other buildings involves using sensors to detect the sway of rope; this means the control comes after an elevator sways. However, the Lotte World Tower approach by Otis detects movement beforehand, allowing for immediate control and timelier response to disaster.

Stack effect is yet another challenge faced by skyscrapers, leading to an issue with pressure differential. To resolve the problem, Otis developed functionality to link the elevator hall doors with screen doors to work together, the first time this was ever done. Stack effect refers to a drastic movement of air inside a tall building due to the inside/outside temperature difference and the pressure difference resulting from the sheer height of the building. As air enters or exits elevators, it sometimes interrupts door operation or causes condensation on the floors. The phenomenon is particularly prominent in skyscrapers during winter months, when temperature differences are severe or when indoor humidity is low.

To mitigate this, Otis installed double-screen doors synced with the Lotte World Tower double-deck elevator doors. The screen doors open and close before the elevators operate, cutting off the influx of external air to help the elevator hall doors open and close without error. The screen doors are designed to protect the elevators from the convection of external air and ensure elevator safety in the 530-m-long shaft.

“Lifeboats” to Safety

Should any emergency occur at Lotte World Tower, four of the 19 Gen2 elevators are immediately used as “lifeboats,” traveling between the safe evacuation zones (Levels 22, 40, 60, 83 and 102) and the ground floor. These evacuation elevators were perfected with a skyscraper safety system that offers water-/fire-resistant features that had been reinforced after 9/11 attack, and feature emergency power backup and shaft pressurization systems to help bring passengers to safety.

The three-step power supply system (normal, backup and emergency) ensures the elevators operate safely in the event of a power outage by fire. When a fire is detected, shafts and elevator halls are pressurized to prevent the introduction of smoke and fire. Closed-circuit TVs on the upper part of the elevator cars, as well as inside the cabs, monitor circumstances before evacuating passengers.

Further, firefighters have access to LCD screens in emergency elevators on which the origin of fire, possible routes and other vital information is provided, informing firefighters who are constantly on the move and enabling them to commit to their rescue missions quicker and more efficiently.

Given its technological uniqueness, the Lotte World Tower project naturally faced myriad elevator challenges. Still, it was completed successfully, thanks to a collaboration involving Otis and the client, Lotte E&C. In addition to Otis Korea meeting its installation deadline, the company was designated one of the top 10 partners contributing to its successful completion.

Credits

- Building owner and Developer: Lotte Property & Development, Lotte Shopping Co., Ltd. and Lotte Hotel Co., Ltd.

- Architect: Kohn Pedersen Fox Associates PC and Baum Architects

- Structural engineer: Leslie E. Robertson Associates and CHANG MINWOO Structural Consultants

- Mechanical engineer: Syska Hennessy Group and Samoo Mechanical Consultant

- Civil engineer: Ove Arup & Partners Hong Kong Ltd. and JINYOUNG Engineering & Consultants

- Life safety and fire protection engineer: Schirmer Engineering and KF UBIS Co., Ltd.

- Curtainwall: ALT Cladding and The Summit Façade

- Vertical-transportation consulting: Fortune Shepler Saling Elevator Consultants

- Building construction: Lotte Engineering & Construction

- Elevator services provider and equipment manufacturer: Otis Elevator Korea

Get more of Elevator World. Sign up for our free e-newsletter.