Maintaining and Adjusting Variable-Torque Brake Controls

May 1, 2018

Important service for variable-torque brakes by Montgomery and its successors

This article discusses the North American vertical-transportation industry’s most common variable-torque escalator and moving-walk brakes: Warner pin-drive armature brakes on Montgomery Elevator Co., Montgomery KONE and KONE units. It gives basic information on and control adjustment procedures for these brakes. Other brakes or equipment are not discussed. Unlike the common fixed-torque brakes used in the industry on elevators, escalators and moving walks, adjustment for these brake controls is not necessarily common knowledge. The technicians reading this will have a better understanding of how these brakes and their controls function, so they are able to better understand the procedures in the OEM manuals.

Learning Objectives

After reading this article, you should have learned about:

♦ How to diagnose problems with the brake itself

♦ The proper procedure for torque testing these brakes

♦ The different types of controls for variable-torque brakes

♦ How to adjust the controls for clean brake opening

♦ How to adjust the controls for proper deceleration (where applicable; the S-Controller has no adjustment)

This information was gained from noncopyrighted documentation through your author’s experience designing units that used these controllers and testing units with these controllers in the field.

This article is not intended to take the place of OEM manuals and should not be used as such. Brakes are a key safety component of escalators and moving walks. Always consult the appropriate manual for the unit being serviced.

When your author started designing escalators and moving walks at Montgomery in 1985, the company had been using Warner ER-825 and 1225 brakes, in production for over a year. These went into production as Model 4000 (glass balustrade) and Model 4500 (solid balustrade) units in January 1984. These units later became known as “HR” escalators. Some — if not all — of the early glass-balustrade moving walks also used variable-torque Warner brakes, as did E5000s. For a short time, Montgomery KONE experimented with Matrix brakes on early E5000 units. All of these have since been replaced with Warner brakes.

The ECO 3000 uses a different style of Warner brake than its pin-drive-armature predecessors. The brake is proprietary to KONE, and, therefore, literature from Warner is not available outside of KONE. This brake will not be discussed in this article.

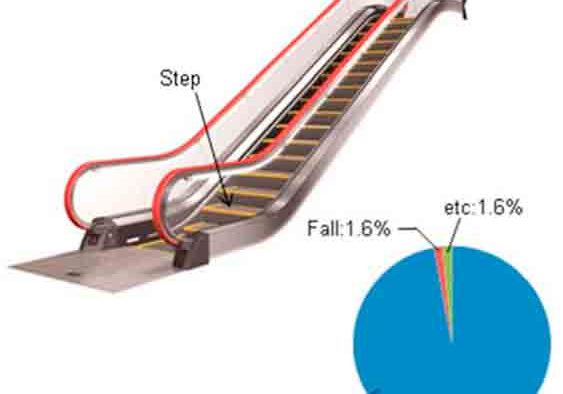

It is very important to note that the Warner ER-825 and 1225 brakes used on these escalators and moving walks are different from the brakes that can be purchased through distributors, even though they look the same. Always purchase brakes from KONE Spares; never substitute other brakes. Warner serial numbers, burnishes and torque tests the escalator and moving-walk brakes it provides to KONE (and provided to its predecessors). This may be important in some litigation, since escalator stops/falls are the most common escalator accident. These brakes also have heavier springs on the drive pins. As time went on, and the controllers became more sophisticated, various sensors were added to the brakes for improvements in safety and maintenance. Warner has an excellent Installation & Operation Manual, Number P-0250-WE 819-0122 for these brakes, which details installation and inspection procedures. Warner manuals are available at www.altraliterature.com under “service manuals, clutches and brakes.”

The data plate located on the brake specifies the minimum static torque each brake must have for continued use. The brake usually requires replacement if a torque test results in a subpar value.

Follow all safety procedures in the Elevator Industry Field Employees’ Safety Handbook, your company’s safety procedures and the Warner literature. Always check slide to verify any adjustments made to these brakes or controls.

Inspecting and Testing the Warner Pin-Drive Armature Brakes

Noise

Begin by listening to the brake while the escalator is running. If it sounds like the brake friction surfaces are rubbing or dragging, the brake release voltage will need to be adjusted (detailed later in this article). The electromagnet in the armature must have the proper voltage in its coil to counteract the permanent magnets (PMs).

Armature Wobble

A mechanic and a helper will need to remove several steps so the brake can be viewed. Start the unit and watch the brake armature while the escalator runs. If it wobbles, try stopping and restarting the unit. If the armature continues to wobble, the drive pins/bushings are most likely worn, and the brake will require replacement. Note that minor wobble is acceptable if it does not cause other problems.

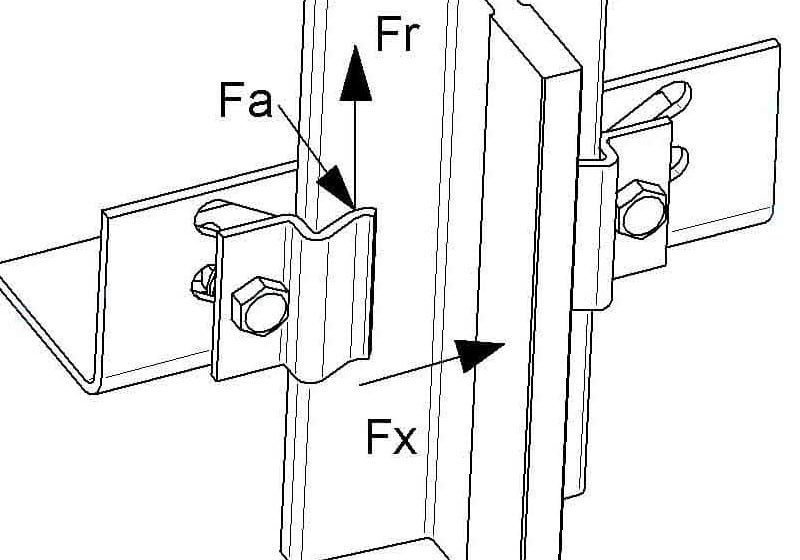

Gap

The brake has an auto-gap feature that, when working properly, keeps the gap between the armature and PM at approximately 1/16 in. Brake release or “pick” voltage must be adjusted properly to check the gap. If the brake won’t release or pick, the brake coil may be open or shorted. If the gap is not 1/16 in., the brake will require adjustment or replacement. As the brake wears, checking the gap becomes more difficult. Some unmaintained brakes have been found in the field with gaps approaching 3/16 in. Near this point, it is possible that the PM may not pull in the armature without delay when power is removed from the brake, causing a longer stopping time or slide than intended.

The gap between the armature and PM must be even all the way around the armature. If it is not, the armature is likely warped, and the brake should be replaced.

Brake Coil

Disconnect both leads to the brake coil. Using an ohmmeter, measure the resistance between the terminals on the coil. Resistance should be:

- ER-825: 203-248 Ohms

- ER-1225: 234-286 Ohms

If the resistance is infinite, the coil is “open,” and the brake must be replaced. Measure the resistance between each terminal on the coil (one at a time) and brake. If the resistance is near zero, the coil is shorted, and the brake must be replaced. It is not possible to replace only the coil.

Wear

These brakes have a wear step machined into them. The thickness of the friction material determines the height of this step. As the brake operates, the friction material wears, and the distance between the armature and the step is reduced. The brake needs to be replaced if the armature covers the wear step. Some brakes have an electronic wear sensor and should be replaced when it indicates 90% wear.

Torque

Static torque is to be measured by rotating the brake in the direction of rotation normal for the unit after the unit is stopped by the brake. Place a torque wrench with the proper capacity and correct socket on the end of the motor shaft. Slowly load the torque wrench in the proper direction. Note the torque when the armature just begins to slip; that is the static torque. The minimum torque, measured after a dynamic stop, is:

- ER-825 (8-in.) brake: 125 ft.-lb.

- ER-1225 (12-in.) brake: 400 ft.-lb.

If the brake does not meet the minimum torque, it may be dirty. Run the unit in its normal direction of travel, stop it two or three times, and retest. Alternatively, if the controller has a burnish function, burnish the brake and retest. If the brake still does not have static torque above the minimum, replace it. If the static torque is only slightly above the minimum during the torque test and doesn’t improve with stopping/burnishing, it is recommended to replace the brake.

When in good condition and maintained properly, these brakes have more than enough capacity to stop and hold an escalator with any load up to the ASME A17.1 brake rated load. Remember that the static torque of the brake is only one part of the variable-torque brake equation.

Variable-Torque Brake Controls

As stated earlier in this article, Montgomery began producing escalators and moving walks with variable-torque brakes in 1984. Since then, Montgomery and its successors have developed and used several different versions of brake controls. The following adjustments assume that the unit has been running for quite some time, that all the components function properly and that the unit is wired correctly. If the brakes cannot be adjusted properly using these instructions, consult the OEM manuals and wiring diagrams (which, hopefully, are still available at the premises).

When adjusting variable-torque brakes, always check the deceleration characteristics after adjusting to ensure nothing went wrong. On the Hi-Volt, ES-24V and ES-24V-B, improper adjustment of the brake boards can cause bad things to happen with deceleration rates. The S-Controller has no adjustments that vary brake torque, but over his career, your author has investigated two units using this controller that had hard stops. Always use a digital voltmeter when performing the following adjustments.

High-Voltage Controller With PM Brakes

This controller was used during 1984-1987. It was called “the high-voltage controller,” since it was used prior to the controllers using 24-V safety strings. To control deceleration, the controller determined how heavily the motor was loaded by reading the phase angle between motor current and voltage. On a lightly loaded unit, it would apply the brake lightly, with a lower torque. On a more heavily loaded unit, it would apply the brake with a higher torque. After approximately 1 s., the controller fully sets the brake at the maximum torque the brake can produce. Note that this controller only controls brake torque in the down direction. A stop in the up direction is with full brake torque. Adjustment of this early PM brake controller is quite complex compared to that of later controllers and is not well known to the industry.

Adjusting the Brake Control

To determine if the brake control requires adjustment, check that the no-load stop distance, or “slide,” measures 5-7 in. This must be an accurate measurement: use tape marks on the handrail/handrail base or step/skirt, and measure with a tape measure. Better yet, use the PMT EVA-625 with a pendant switch and tachometer. If the slide is not 5-7 in., adjust the brake control as follows:

- Switch off the circuit breaker on the controller and remove all the motor wires from all the motor overload terminals.

- Switch on the controller circuit breaker. The red LED on the upper left of the printed circuit board (PCB) should be on and the BRP relay energized.

- Connect a voltmeter to the controller BR1(+) and BR2 brake output terminals.

- When performing this following step, the brake(s) will open, or pick, so make sure nothing is on the step band: start the unit in the down direction, noting that all the motor wires are still disconnected from all the motor overload terminals.

- ER-825 Brake: Use the 200-ohm, 25-W adjustable resister (on the PCB above the relays) to adjust the voltage across BR1 and BR2 to 90 VDC. Moving the slider left will increase the voltage. The brake should now be open, or “picked.”

- ER-1225 Brake: Use the 200-ohm, 25-W adjustable resistor (on the PCB above the relays) to adjust the voltage across BR1 and BR2 to 90 VDC. Moving the slider left will increase the voltage. Adjust the rheostat (wired in series with the BR1 terminal and the brake) to get a brake voltage of 57-59 VDC. The brake should now be open, or “picked.”

- Switch off the controller circuit breaker and rewire the motor wires into the motor overload terminals.

- Switch on the controller circuit breaker and start the unit in the down direction.

- Connect one voltmeter lead to the test point TP-1 on the PCB and the other to ground. The meter should read 13.5–18.5 VDC. Note that motors other than Montgomery standard motors may have a TP-1 voltage as low as 10 VDC.

- With the unit running down, connect one voltmeter lead to the test point TP-2 on the PCB and the other to ground. Adjust the potentiometer P1 so that the voltmeter reads 1.1 VDC. Let unit run for 30 min.

- After 30 min., adjust potentiometer P1 so that the no-load stop distance, or “slide,” measures 5-7 in. Again, this must be an accurate measurement — use tape marks on the handrail/handrail base or on the step/skirt and measure with a tape measure. Better yet, use the PMT EVA-625 with a pendant switch and tachometer.

- If the slide is less than 5 in., raise the TP-2 voltage. If it is greater than 7 in., lower the TP-2 voltage and retest until the slide is 5-7 in.

- Start and stop the unit a few times to make sure the brakes function properly.

A brake board that is out of adjustment can cause changes in the deceleration characteristics with this controller. Voltage at TP-2 has been observed to have been adjusted higher than normal to give a longer slide. Presumably, the technician thought that would give a smoother stop. However, the unit coasted until the brake applied fully, in slightly less than 1 s., causing a high deceleration stop. Make sure the empty slide down is 5-7 in.

ES-24V Controller

This controller was used from mid 1987 until the advent of the microprocessor-controlled ES-24V-B. It was Montgomery’s first “low-voltage” controller: all of the truss wiring, with the exception of motor/brake wiring, was 24 VDC. The brake control is a closed-loop system. It compares the motor-driven tachometer voltage to the voltage at the brake card.

When this system is working properly, it will stop the unit nicely in both the up or down directions, with no or full passenger load, at approximately an average deceleration rate of 2 fps2. In my experience, the tachometer voltage drops over time, and this can cause the unit’s stopping characteristics to change. Unlike the ES-24V-B controller, this controller will not give a tachometer fault if the tachometer voltage drops too low, so check the tachometer output regularly. The controller fully sets the brake at the maximum torque the brake can produce after less than 1 s. Proper adjustment of the brake control board on this controller is not always common knowledge in the field.

Adjusting the Brake Control

Though perhaps not necessary for minor adjustments, a good practice is to always turn the P1, P2 (if equipped) and P3 potentiometers fully counterclockwise prior to beginning the adjustment procedure. Then, they can be adjusted clockwise to get the desired results. To adjust the brake control:

- Switch on the controller circuit breaker.

- Place the “NORM/OFF/CONST” switch on the relay board to the “CONST” position. Note that when turning the switch to “CONST,” the brake(s) will open, so make sure nothing is on the step band.

- Connect a voltmeter to the R6 resistor located on the relay board to the right of the heat sink. Note that the left end of the resistor is positive.

- Adjust potentiometer P3 on the brake board so voltage is set per the table below:

- The brake should now be open or picked.

- Turn the “NORM/OFF/CONST” switch to “NORM.”

- Start the unit in the down direction. LED3 (red) should be on, indicating that there is output from the tachometer.

- If the brake still drags, adjust potentiometer P3 a few turns either way until the brake is quiet. The voltage across the R6 resistor should still be within tolerance.

- Adjust potentiometer P1 clockwise until LED1 and LED2 either both go out completely or both alternate on and off rapidly. The adjustment of P1 can be performed regularly to ensure the unit stops as designed. If it is a two-speed unit, the “HI/LO” switch must be set to “LO” during this adjustment. This adjustment is for the low speed on a two-speed unit.

- To adjust the brake control for proper braking during high-speed operation on a two-speed unit, set the “HI/LO” speed switch to “HI” and adjust potentiometer P2 clockwise until LED1 and LED2 either both go out completely or both alternate on and off rapidly. The adjustment of P2 can be performed regularly to ensure the unit stops as designed.

- Accurately check the slide.

- Start and stop the unit a few times to make sure the brakes function properly.

The brake/brakes are now adjusted properly. After very little run time, just one of the green LEDs will be on. The brakes should still perform correctly for some time. However, as time goes by, the tachometer voltage will degrade, slowly changing the deceleration characteristics of a stop. If the tachometer fails or if this board is not kept in adjustment as described, it is possible to have a short delay before the application of significant torque, followed quickly by the application of full torque. These conditions can obviously change the intended deceleration characteristics.

Some of these controllers have had the brake board misadjusted so that there is close to a 1-s. delay in application of significant torque. With this controller, it pays to keep the brake board adjusted properly and to check tachometer voltage with the unit, running at rated speed to ensure it is within specification. Both tasks are easy to perform and should only take a couple of minutes once the controller is out of the unit. Replacing the tachometer is recommended if its output drops below 14 VDC, measured between TK1 and TK2 on the relay board (or in the upper J-box) at rated speed.

The nominal tachometer output at various speeds is shown in the table below:

It is important to have the correct brake board installed in the unit. There are different brake boards depending on the type of starter panel. I have seen some ES-24V controllers used on higher rise escalators equipped with a soft start using a very special brake board. These units have a small overspeed board in the controller. The brake board for these units has a “broken trace” and a blue wire soldered to the brake board that the electrical guys call a “flying lead”. Consult the Parts Guide or KONE Spares on the proper board for the unit in question.

ES-24V-B Controller

This controller replaced the ES-24V controller. It was Montgomery’s first microprocessor escalator/moving-walk controller and can be identified by the CPU board on the controller door. (All of the door labels your author has seen for this controller still say “ES 24V.”) It can store fault codes to help diagnose problems with the escalator.

Brake operation is like that of the ES-24V controller, and the brake-control adjustment is similar. This controller monitors tachometer output and will generate a tachometer fault (TF) if the tachometer voltage is not within +10% to -25% of the voltages in the table above at startup or while running to a value of approximately 2 VDC. The TF LED on the left side of the CPU board will be on to indicate a TF has been generated. It can be cleared by cycling the controller circuit breaker. Just like the ES-24V controller, the controller fully sets the brake at the maximum torque the brake can produce after less than 1 s.

A brake fault (BF) will be generated if the stopping profile was exceeded during a stop. The BF LED on the left side of the CPU board will be on if a BF is generated. A BF is cleared by pushing the “BF Reset” button at the upper left of the CPU board. There are different brake boards depending on the type of starter panel, and whether the unit is single or dual drive. To make sure the unit has the correct boards installed, refer to the Parts Guide or contact KONE Spares. Proper adjustment of the brake control board on this controller is not always common knowledge in the field.

Adjusting the Brake Control

Adjustment of the ES-24V-B is very similar to that of the ES-24V. Like that board, a good practice is to always turn the P1, P2 (if equipped) and P3 potentiometers fully counterclockwise prior to beginning the adjustment procedure. Then, they can be adjusted clockwise to get the desired results. To adjust the brake control:

- Switch on the controller circuit breaker.

- Place the “NORM/OFF/CONST” switch on the relay board to the “CONST” position. The CPU board LED display should read “00.” Note that when turning the switch to “CONST,” the brake(s) will open, so make sure nothing is on the step band.

- Connect a voltmeter to TP2 and TP3 on the relay board, just below the heat sink, to check the voltage across the R6 resistor.

- Adjust potentiometer P3 on the brake board so voltage is set per the table below:

- The brake should now be open or picked.

- Turn the “NORM/OFF/CONST” switch to “NORM.”

- Start the unit in the down direction. LED3 (red) should be on, indicating output from the tachometer.

- If the brake still drags, adjust potentiometer P3 a few turns either way until the brake is quiet. The voltage across the R6 resistor should still be within tolerance.

- Adjust potentiometer P1 clockwise until LED1 and LED2 either both go out completely, or both alternate on and off rapidly. The adjustment of P1 can be performed regularly to ensure the unit stops as designed. Although your author has not adjusted a brake board in an ES-24V-B two-speed controller, it should be similar to the adjustment for an ES-24V two-speed controller. If a two-speed unit with potentiometer P2 on the brake board is being adjusted, this adjustment is for the low speed. The two-speed unit’s “HI/LO” switch must be set to “LO” during this adjustment. This adjustment is for the low speed on a two-speed unit.

- To adjust the brake control for proper braking during high-speed operation on a two-speed unit, set the “HI/LO” speed switch to “HI,” and adjust potentiometer P2 clockwise until LED1 and LED2 either both go out completely, or both alternate on and off rapidly. The adjustment of P2 can be performed regularly to ensure the unit stops as designed. Always accurately check the slide after making these adjustments.

- Start and stop the unit a few times to make sure the brakes function properly.

Once the brake(s) are adjusted properly, after very little run time, just one of the green LEDs will be on. The brakes should perform correctly for some time. Just like the ES-24V controller, as time goes by, the tachometer voltage will degrade, slowly changing the deceleration characteristics of a stop. However, the “B” controller will generate a TF (tachometer fault) when the tachometer output falls to 75% of the nominal output at the unit’s rated speed and stop the unit. If the tachometer fails while the unit is running, a TF will also be generated, and the unit will stop. However, if the brake board is not adjusted properly, it is possible to have a short delay before the application of significant torque, followed quickly by the application of full torque, just like the ES-24V controller. This condition can change the intended deceleration characteristics. Like escalators with the ES-24V controller, some escalators with this “B” controller have their brake board misadjusted so there is close to a 1-s. delay in application of significant torque. It is important to keep this controller’s brake board adjusted properly. The adjustment is easy to perform and should only take a couple of minutes once the controller is out of the unit.

S-Controller

The smart controller followed the ES-24V-B controller. It also uses a microprocessor to control the operation of the escalator. This controller stores up to 99 faults in the register before writing over them. It also uses a motor-mounted encoder to provide feedback to the microprocessor and brake board. This takes care of any problems related to tachometer output degradation over time and provides better stopping data, among other improvements. There are different brake boards depending on motor RPM and brake size. To make sure the unit has the correct boards installed, refer to the Parts Guide or contact KONE Spares.

When functioning properly, the S-Controller decelerated the unit smoother than any controller before it. The only adjustment is for brake opening, or “pick.” The deceleration is fixed, with no adjustment. This, however, does not mean nothing can go wrong. Some escalators with S-Controllers have had stops up to 5 fps2 peak deceleration. (ASME A17.1 allows 3 fps2 maximum.) This is a rare occurrence but can happen. Usually, S-Controllers stop the unit beautifully. Note that some E5000 escalators originally used a brake manufactured by Matrix. These were replaced by Warner brakes.

Adjusting the Brake Control

Though perhaps not necessary for minor adjustments, a good practice is to always turn the R10 potentiometer fully counterclockwise on all brake boards prior to beginning the adjustment procedure. Then, adjust clockwise to get the desired results. To adjust the brake control:

- Turn the “CONST” switch on the main CPU board to the “OFF” (center) position.

- Connect a voltmeter to the “current+” and “current-” points on the first brake board. Turn potentiometer R10 until the voltmeter reads per the table below:

- When performing this step, the brake(s) will open or pick, and the unit will run, so make sure nothing is on the step band: turn the “CONST” switch to “RUN,” and start the unit in either direction. (Previous controllers were always started only in the down direction during brake-board adjustments.) The brake(s) should open, or pick, cleanly.

- If the brake(s) don’t pick cleanly, adjust R8 on that brake’s brake board a half turn in either direction to fine tune the pick.

- Perform the above steps on each additional brake board.

- Start and stop the unit a few times to make sure the brakes function properly.

- If the controller is displaying brake faults, consult the S-Controller Setup Guide. If one is not available, contact KONE Spares.

- Faults can be cleared from the CPU board or with a service tool. There are three types of resets: power-up (by cycling the disconnect), master (by pressing the processor reset button SW4 on the CPU board) and manual (by pressing SW5 on the CPU board, which clears MR faults one at a time). Note that much more can be done by using the service tool.

When the following LEDs on the brake board are on, they communicate the following information:

- LED2 (5V): Indicates 5 VDC is present at the brake board

- LED3 (100V): Indicates 100 VDC is present at the brake board

- LED4 (BCOP): Indicates the brake control is operating properly

- LED5 (HEART): When blinking, indicates the brake board is communicating with the CPU

There are several faults that relate to operation of the brake. Consult the S-Controller Setup Guide.

Learning-Reinforcement Questions

Use the below learning-reinforcement questions to study for the Continuing Education Assessment Exam available online at www.elevatorbooks.com or on p. 139 of this issue.

♦ Which are the most important parts of Warner pin-drive armature brakes to inspect and test?

♦ Which documentation is available for the brakes mentioned here, and where can it be obtained?

♦ What are the conditions under which each of the brakes mentioned here should be replaced?

♦ Which technological advances were made over the years in the models of controllers described here?

♦ What does each LED on each controller mentioned in this article indicate?

Get more of Elevator World. Sign up for our free e-newsletter.