Maintenance Support Tools for Elevator Equipments that use Cellular Phones

Nov 1, 2011

This paper was presented at  Lucerne 2010, the International Congress on Vertical Transportation Technologies and first published in IAEE book Elevator Technology 18, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers (website: www.elevcon.com).

Lucerne 2010, the International Congress on Vertical Transportation Technologies and first published in IAEE book Elevator Technology 18, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers (website: www.elevcon.com).  This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

Key Words: Cellular phone, data linkage, maintenance tool

The benefits of adopting cellular phones as a maintenance support tool for elevator equipment are outlined.

by Yuji Sasamori, Toshiyuki Kotani, Shuichi Kumura and Takayuki Hayashi

Abstract

Cellular phones have become widespread around the world, and they are used as communication tools in a diverse range of situations. While the number of installed elevators is increasing day by day. Therefore, we adopted cellular phones as a maintenance support tool for elevator equipment. The efficiency of maintenance work should be high, and service providers must complete all maintenance work and adjustment, and then make their report promptly. In this paper, we describe our work to implement all functions required by service staff in a cellular phone, allowing a substantial reduction in the time required.

1. Introduction

1.1 Design Concept

Periodical proper maintenance needs for ensuring safety-operation of elevators. It is essential to secure and train maintenance personnel because of depending upon first-hand maintenance by individual personnel. But the existing labor-intensive approach is not practical when efficient maintenance of the increasing number of elevators is to be accomplished with a limited number of maintenance personnel. A maintenance system should require the following three goals:

- Easy data input to the work report and sharing information.

- Review of the functions required for maintenance tools.

- Enhanced customer convenience.

We were reviewing the work process itself so that highly convenient cellular phones can be employed for the maintenance of elevators, and is also making an effort to share information about the maintenance of elevators among maintenance personnel by quickly reporting work results from the field, thus enhancing the work efficiency. Furthermore, we take full advantage of these cellular phones, regarded as work support tools based on information technology (IT), to ensure high-level security and improve customer service.

1.2 Functions

(1) Real-time data acquisition through a simplified reporting procedure:

To report the results of work that has been completed on the day, the maintenance worker has so far needed to return to his/her place of business or workplace and enter the work results into an in-house network system using a personal computer. We have developed a system that allows maintenance personnel to enter work results into the in-house network system using a work reporting tool in the form of a cellular phone without having to return from the field to the place of business. In addition, real-time sharing of elevator information makes it possible to respond quickly even when an abnormality is detected in an elevator.

(2) The enhanced function of the elevator maintenance tool:

Because it has been almost 20 years since the dedicated tool used to refer to or rewrite various types of data about elevators was developed, problems such as an insufficient number of terminals and failures resulting from deterioration over time can be seen. To overcome these problems, we have reviewed the function of the elevator maintenance tool and added a new function that helps staff to perform work requiring high-level skill. Furthermore, we have developed a dedicated tool for performing data transmission and reception via Bluetooth® (Bluetooth is the property of its trademark owner) communication to provide high-level security.

(3) Notification to customers:

When an elevator was to be inspected, users could only discover that the elevator was unavailable when they were about to use it. In addition, the report prepared by maintenance personnel after completion of inspection work was handed over directly to the customer. To avoid this inefficient procedure, we use IT to provide a service for informing customers of the start and end of elevator inspection in a timely manner, and for allowing customers to access a special web site to view the results of the inspection work.

2. Requirements Of The Existing System

It is important to save time by sharing on-site information efficiently and improving the work efficiency during the direct and indirect work processes carried out by maintenance personnel. The existing work of maintenance personnel is roughly classified into the following two jobs.

2.1 Periodical Inspection

Maintenance work for periodical inspection mainly constitutes checking the operation of elevators and the condition and operation of other devices. For this purpose, inspection needs to be performed efficiently within a limited period of time according to the specified items to be inspected. At the end of maintenance work, the results of inspection are recorded to indicate that the maintenance work has been finished, and the completed record is handed over to the customer in the form of an inspection report. Furthermore, after the maintenance work is completed on site, the maintenance personnel returns to his/her place of business, such as a business office or a service station, carries out various accounting procedures on the day, and uses a personal computer to register in an in-house network system a summary of reported items and messages, handover processes, and inspection results.

2.2 Measure against mal-function of elevator

If an elevator mal-functions, maintenance personnel is quickly dispatched to the site in all days, and attempts to fully ascertain the actual conditions on site in order to restore the normal operations.

Information sharing is indispensable in order to quickly grasp the conditions of the elevator and attain quick restoration from the abnormal state through efficient inspection work. We focused attention on highly convenient cellular phones. It is available for information sharing under almost any conditions to achieve high efficiency of maintenance work.

3. New Functions

3.1 Cellular Phones linking to the In-house network system

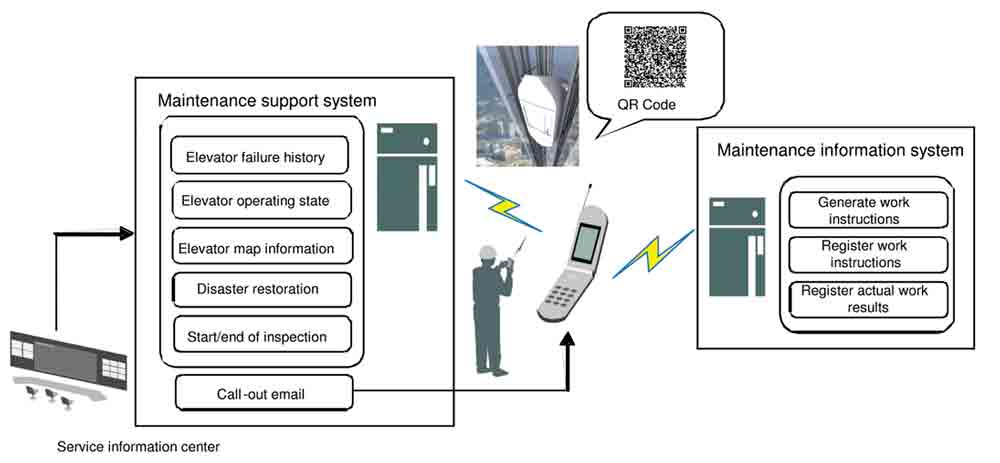

The required functions of a maintenance information system for supporting maintenance work include generation of work instructions, inputting and generation of work reports, management of information about customers of elevators, and so forth. Maintenance personnel has conventionally entered information using a terminal such as a personal computer on his/her desk or a personal digital assistant. In addition, the service information center that monitors the conditions of elevators 24 hours a day via a remote monitoring terminal to respond to inquiries from users is provided with a maintenance support system that stores conditions and failure histories of elevators, as well as map information of elevators. As shown in Figure 1, depicting a cellular phone linking to the in-house network system , information can be transmitted from the cellular phone to the basic system.

We have developed a new cellular phone application using the BREW® (a trademark or a registered trademark of Qualcomm, Inc.) application to improve field work by allowing the cellular phone of maintenance personnel on site to be wirelessly connected to the in-house network system.

First, the maintenance personnel downloads the work to be performed on the day from the maintenance information system via a network system provided by KDDI Corporation to check work instructions for the day. When arriving on site, the maintenance personnel reads in a QR code® (A QR code is a type of two-dimensional barcode for representing information in a black and white matrix pattern and is a registered trademark of DENSO Wave Incorporated) attached on each elevator using the camera in his/her cellular phone and, based on the read information, checks the operating states (remote inspection information, maintenance information, failure history, information about unresolved incidents , and customer information) of the elevator to notify the start of work to the service information center. At the completion of necessary inspection and maintenance work, the maintenance personnel fills in the work report using his/her cellular phone to send information indicating that the work has been completed. At the same time, the completion of work is automatically sent to the service information center to upload data on the report to the maintenance information system. Through this workflows, high operability and off-line operation, which does not require constant connection to a network or a system, are achieved with the BREW® application incorporated in the cellular phone. For this reason, even at a site where the communication conditions are not satisfactory, work results can be reported without difficulty by temporarily retaining the input data that could not be uploaded in the cellular phone and then uploading the retained input data when the communication conditions become satisfactory. Furthermore, man-hours can be calculated accurately by reflecting in the maintenance information system the start and completion time of work read via the QR code® attached to each elevator.

3.1.1 Sharing of information about elevators

The following functions are now available as a result of cooperative linkage to the in-house network system being accomplished with cellular phones playing a central role.

(1) Mapping service:

In coordination with a map system, the statuses of installed elevators (operating normally, being inspected, or faulty) can be checked on the map by reflecting the current work being performed by maintenance personnel upon building information on a map. This has enabled the service information center and branch offices to visually check the current statuses of elevators under their management.

(2) Restoration from abnormal state and disasters:

In the event of a widespread disaster, it is necessary to inspect all elevators within areas under management, promptly collect information about the progress of restoration, and distribute it as in-house information. With the existing approach, however, data such as the progress of restoration from a disaster was manually collected based on information acquired from maintenance personnel by telephone, and therefore, the service information center had difficulty in grasping the progress of patrol inspection in a real-time manner. It is now possible to grasp the progress of inspection and the completion rate in a real-time manner at the service information center by recording the actual results of inspection work (start and completion of inspection) on site via the QR codes® using cellular phones.

(3) Call-out function:

In the event of a failure of an elevator, the service information center calls out maintenance personnel. A call-out instruction is given to maintenance personnel requested to take action by sending an email to his/her cellular phone. The maintenance personnel who has received the email can log in to the cellular phone website using his/her cellular phone to check the failure. With the report function by email and via a cellular phone website solely for use by maintenance personnel, a call-out instruction can be given to the maintenance personnel and the status of the elevator at the destination can be promptly checked, even if the maintenance personnel is out of the office.

3.2 Enhanced Function of the Elevator Maintenance Tool

Data about elevators has so far been referred to or updated by connecting an elevator maintenance tool to the control device or remote monitoring device via an optical fiber cable. We have developed a communication adapter serving as an interface between a cellular phone and the control device in order to fulfill this function using a cellular phone. The external appearance of the communication adapter is shown in Figure 2. While an optical fiber cable is used to connect to the control device in the same manner as before, Bluetooth® communication is employed between the communication adapter and a cellular phone. Elevators can now be set and checked securely using a BREW® application installed in the cellular phone.

Table 1 lists the specifications of the communication adapter: Bluetooth® module Class 2 incorporated; powered by a battery, with an operating voltage of 2.4 to 3.3 V; and USB 1.1 and optical fiber connector provided as external interfaces.

3.2.2 Additional functions

In the event of abnormal state while an elevator is under maintenance, it is necessary to quickly grasp what is happening on site to smoothly restore the elevator operation. In order to recover from abnormal state, data that is required for restoration or useful for primary determination needs to be collected from the elevator. This type of data has conventionally been collected by manually sending a command to the elevator. For this reason, if the collected data was erroneous, there was a risk of lengthening the time required for restoration. In addition, a high level experience and skill of a maintenance personelwas required to collect data.

We have incorporated into the cellular phone application a function for automatically collecting data required for failure restoration regardless of the skill level, and we further developed a system for allowing necessary commands to be optionally registered. Figure 3 shows the outline of a system that enables collected data to be registered using a personal computer (via a network and a cellular phone gateway server provided by KDDI) on the Internet and also to be downloaded into a cellular phone.

3.3 Enhancing Customer Convenience

We provide an IT-based service to enhance customer convenience with regard to their elevators. Figure 4 shows the outline of a service for notifying users of inspection by email with the use of a QR code read in when maintenance personnel starts and ends inspection of an elevator, as well as the outline of a system for enabling customers to view, using a personal computer, the inspection results sent by maintenance personnel via a cellular phone.

3.3.1 E-mail notification of inspection start and end

Because elevators cannot be used during inspection, users may experience some inconvenience. Users will be able to avoid such inconvenience if they are informed of when inspection of the elevator is scheduled to start and complete because the elderly and children have difficulty in walking up stairs, particularly of high-rise buildings.

To enhance user convenience, Toshiba Elevator and Building Systems Corporation has developed a service for notifying users of the start and completion of inspection by email with the use of a QR code® read in when maintenance personnel starts and ends inspection of an elevator. Users need to pre-register their mail addresses in the portal site (web server). When maintenance personnel reads in the QR code® for the start of inspection work, an email notifying them of the start of inspection is distributed from a mail delivery server in coordination with the maintenance support system to the registered mail addresses. Also at the end of inspection work, when the maintenance personnel reports the completion of inspection to the maintenance support system, a notification indicating the completion of inspection is distributed to the registered mail addresses.

3.3.2 Function for viewing inspection work reports on the web

Maintenance personnel have conventionally prepared a work report on site and handed it over to the customer at the end of inspection of the elevator. This has involved so many documents, making management of the elevator by the customer complex. To overcome this problem, we have developed a service that allows customers to view on a personal computer the results of inspection work in real-time, anytime and anywhere, as long as they can connect to the Internet, after maintenance personnel sends a notice of completion of inspection of an elevator from his/her cellular phone to the maintenance information system. Furthermore, because historical data (for the past three years) is managed electronically rather than in the form of written reports, elevators can be managed more easily.

4. Conclusion

4.1 Data Linkage with Cellular Phones Playing a Central Role

We have succeeded in reducing the burden of registering inspection results in the in-house network system upon returning to the office by linking cellular phones with various types of in-house network system s. This means that the burden on maintenance personnel has beenreduced. Table 2 shows work results actually registered using cellular phones in domestic places of business of Toshiba Elevator and Building Systems Corporation (excerpts from November 2009 data).

While the number of tasks assigned to maintenance personnel involved with maintenance work of elevators in Japanese places of business of Toshiba Elevator and Building Systems Corporation was 88,039, the number of tasks registered in in-house network system s via cellular phones was 79,716. At present, more than 90% of work results in domestic places of business are sent to in-house network system s using cellular phones.

4.2 Advantage of the Enhanced Maintenance Tool

We have accomplished a system that can reduce the time required by maintenance personnel to manually collect information of elevators using a tool dedicated to maintenance and that, in the event of a failure of an elevator, can collect data required for failure analysis regardless of the skill of the maintenance personnel. The function is as shown in Figure 5.

After the type of the elevator and a data collecting program according to the application are optionally downloaded from the cellular phone gateway server (MGW server), necessary data is automatically stored in the data folder of the cellular phone by executing the data collecting program for the elevator. Information can be shared among maintenance personnel through email of the collecting data. Consequently, anyone can perform failure analysis merely by executing the same data collecting program for elevators, and therefore, failure analysis time was reduced drastically.

5. Future

We have succeeded in building a system for registering and viewing results of maintenance work on elevators and also information acquired from elevators using cellular phones. In the future, maintenance personnel will be able to carry out work such as inspection and parts replacement with appropriate timing by formulating work instructions based on information about elevators input via a cellular phone. In addition, we plan to incorporate into cellular phones new functions for enabling higher-level inspection work, such as referring to manuals required at the time of work, and for further enhancing the tools dedicated to maintenance of elevators. When these functions are realized, the quality of maintenance work for elevators will be further enhanced.

We started maintenance operation by using a new support tool for maintenance personnel. The fast-evolving cellular phones is inspiring us to enhance the work efficiency by maintenance personnel on site. This improvement in the on-site work process where cellular phones play a central role is still developing. There is an ongoing advancement in performance, function, and communication speed of cellular phones. In the future, we will accomplish higher-level maintenance work and derive greater customer satisfaction by utilizing cellular phones.

Get more of Elevator World. Sign up for our free e-newsletter.