Kleemann’s New Transportation System for Vehicles

Feb 1, 2011

Kleemann recently launched a new hydraulic system designed to transport vehicles that allows for the maximization of the net carrier area.

by Nickos Spyropoulos

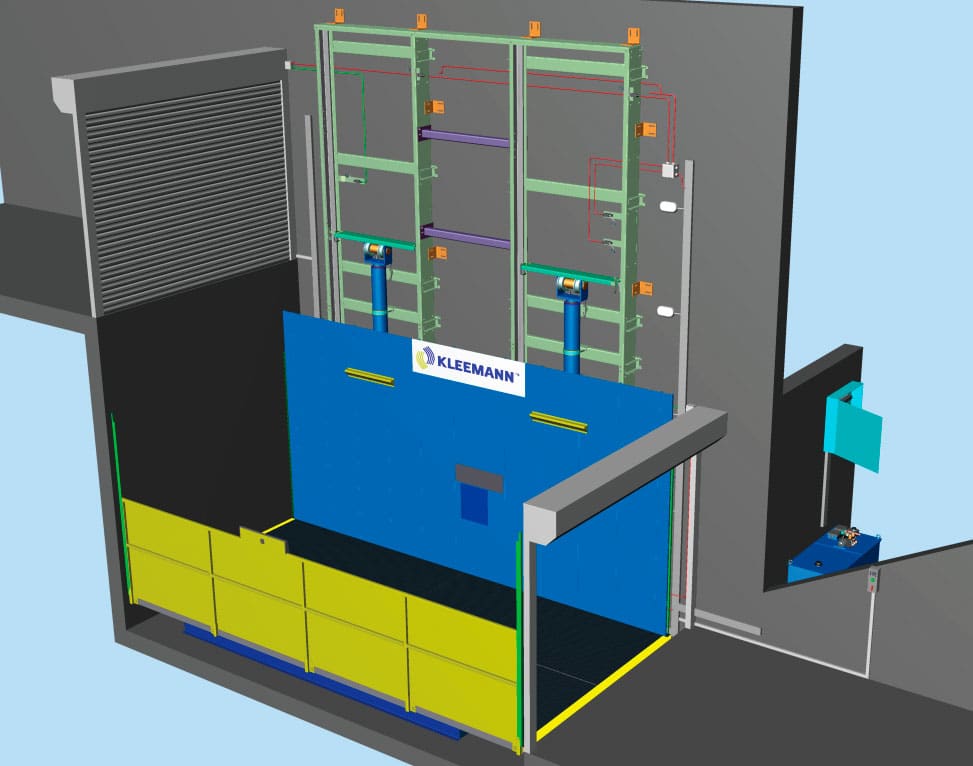

European lift-system manufacturer Kleemann recently launched a new system designed to transport vehicles. Dubbed the KTS 2/M, the hydraulic lifting system is designed and manufactured according to the European Machinery Directive 2006/ 42/EC. The product is comprised of a hydraulic indirect-acting system using two jacks with the carrier fitted on a cantilever type frame. This configuration allows for the maximization of the net carrier area with regard to the shaft dimensions. The suspension of the carrier is achieved by four chains.

Basic Specifications

The KTS 2/M can serve up to four stops. Its rated speed is limited to 0.15 mps, while its maximum travel reaches 12 m. Its rated load is currently up to 2200 kg, though that is planned to see extension to up to 3000 kg by the first half of 2011.

The Carrier

The carrier has a rigid sidewall in order to avoid contact with the mechanism and a simple balustrade on the other side to minimize the risks of accidental fall. The length of the carrier can be between 4,500 and 5,500 mm, while the width can reach 2,500 mm. These dimensions are intended to accommodate a wide range of vehicles. Safety light curtains located at the carrier entrances ensure that the car is parked at the right position. The carrier is also equipped with operation controls, and lighting and stopping devices.

Shaft and Machinery Space

The shaft can be fully or partially enclosed and comprised of concrete, brick or steel construction. The minimum headroom is 2,400 mm, and the minimum pit is 400 mm. Landing entrances are equipped with roller shutters that open and close automatically and an obstacle-sensitive edge that stops the closing motion when activated. The clear height of landing entrances is a minimum of 2,000 mm. The minimum shaft dimensions are 2,500 mm wide by 4,540 mm long.

The machinery (power unit and controller) can be installed either in a machine room or machinery cabinet located near the shaft. The power unit is provided with a manual-lowering valve, as well as a hand pump for manual lifting of the carrier in case of safety-gear tripping.

Operation and Safety Components

The operation philosophy is similar to that of lifting platforms (i.e., hold-to-run controls inside the carrier and automatic controls at the landings, with priority always given to the carrier controls through a carrier weight-detection device, which, when activated, cancels all landing calls). The driver of the vehicle can access the carrier operation panel, remaining in his or her seat through the car window, while a remote control is an option only for the landing calls.

The system is also equipped with safety gears, rupture valves, an electrical anti-creep system and electromagnetic lock valves in order to avoid uncontrolled movements of the carrier. The KTS 2/M is allowed to be used as a crossover platform for cars up to 2200 kg from one side to the other, while the carrier is stationary at a landing.

The KTS/2M has been EC Type examined and certified according to Annex IX of the new Machinery Directive 2006/42/EC and presents an ideal solution for the transportation of vehicles in terms of cost, reliability, safety and user-friendly design.

Kleemann’s Product Range

Kleemann was founded in 1983 and designs and manufactures a wide range of lifting systems, such as complete hydraulic and traction passenger lifts, goods lifts, lifting platforms, stair lifts, escalators, moving walks and scissors goods lifts. It has a number of offices and production facilities throughout Europe in such countries as Greece, Turkey and Serbia.

Get more of Elevator World. Sign up for our free e-newsletter.