Italian special lifts designer’s history and recent major projects

Maspero Elevatori in one of the leading European firms now operating for top-range elevators. During its almost 50-year history, Maspero has been involved in projects around the world, including the Hermitage Museum in St. Petersburg, Russia, Ferrari and Fiat headquarters in Maranello and Turin, both in Italy, the British Museum in London and the new Qatar National Library, as well as other luxury penthouse projects from Singapore to Santiago, Chile.

Maspero’s production is certified according to the latest European regulations (European Lift Directive 95/16 CE and pr EN 81.22 for inclined lifts) and capable of meeting international and local standards, ranging from American Society of Mechanical Engineers to Russian codes.

History

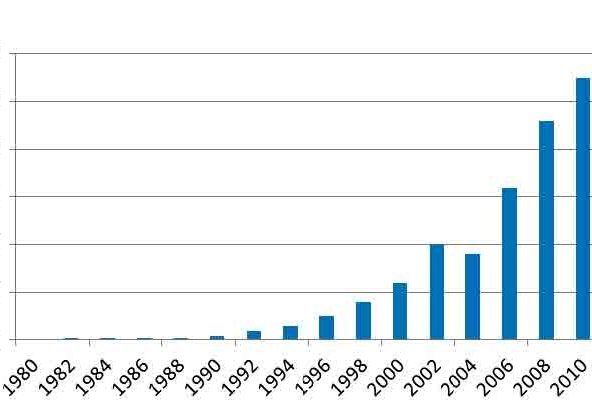

Maspero was established in 1966 in Como, Italy, and started its exports in 1972. In the 1980s, the company opened sales branches in Milan and Genova. In the 1990s, Maspero moved to its new headquarters in Apppiano Gentile with test towers and gained UNI EN ISO 9001 Quality Certification. Today, Maspero is a multi-national group with branches and sister companies in France, Switzerland and India as well as many sales offices in Italy.

Despite the continuous growth of the past decades, Maspero never abandoned its particular care for customer’s needs. Maspero’s core business still consists of a unique blend of panoramic lifts, often with demanding technical specifications, inclined elevators and special goods-lifts. Challenging design and environmental conditions often give Maspero the opportunity to provide designs to meet any vertical-transportation need from architects, developers and public authorities.

Regulations and Certifications

Maspero complies with various Italian, European and international regulations and certifications. In addition, the following equipment complies with European Directive 95/16/EC: electric lifts with ropes, hydraulic lifts with and without machine rooms; electric Koala model without machine room; inclined Climber model; and its Koala inclined model without machine room.

Maspero also complies with EN 81-22 regulations for inclined lifts and strives to meet regulations for architectural obstacles. Its Climber inclined lift, Koala lifts and hydraulic lifts are EC certified. Masepro has also received an Italian Certification of Company Quality Systems and holds an ISO 9001 certification.

Recent Projects

Excelsior

In 2011, Maspero provided six elevators, four escalators and three moving walks for Excelsior. The structure is divided into seven floors, enclosed in an architectural shell and includes a group of floating elevators. The elevator equipment includes:

- Number and type: five Koala 3 machine-room-less elevators

- Travel: ranging 6.8 m to 16.85 m

- Rated load: ranging from 870 kg to 1125 kg

Maspero also installed the following elevator and escalators:

- Number and type: one roped elevator

- Travel: 11.2 m

- Rated load: 1400 kg

- Speed: 1.6 mps

- Four escalators with a 35° incline

- Three moving walks with a 12° incline

Kek Lok Si Temple

In 2002, the temple received its first inclined elevator, which was installed at the bottom of the structure. In 2004, Maspero supplied a second inclined lift with the same specifications. In 2011, the temple was expanded, and two additional units were installed at the structure’s new bottom to transport pilgrims and visitors from the ground floor to one serviced by elevators.

The most recent installation includes the following specifications:

- Incline: 16°

- Travel: approximately 106 m

- Rated load: 3000 kg

- Speed: 1 mps

- Stops: two

- Car: panoramic

- Machine location: top of shaft

Hermitage Museum

Maspero supplied and installed a hydraulic platform with a telescopic car frame and guiding system for the Hermitage Museum. The platform was certified as a one-off piece due to its telescopic guiding system and drawbridge connecting the car and landing-door sills. Maspero was tasked with designing an installation that would allow passengers with impaired mobility access to the top floor via a bespoke lifting unit without a conventional enclosed shaft.

The platform was equipped with a two-stage telescoping car frame, hidden by round steel cladding and lifted by a conventional hydraulic unit. The platform features a half-height car balustrade and central opening doors.

The specifications include:

- Travel: 5.6 m

- Rated load: 3500 kg

- Speed: 0.2 mps

- Stops: two

Get more of Elevator World. Sign up for our free e-newsletter.