Building effective scorecards and integrating remote monitoring

by Sean Madden

If it had not been for key performance indicator (KPI) scorecards, Madden Elevator would have never made it through many of the business trials and tribulations that every business eventually encounters. Someone once told me, “Systemize the predictable so you can humanize the unexpected.” Life will always throw curveballs at our companies and our teams. When life and family unexpectedly throw you or your team a curveball and you can systemize how to solve the KPI scorecard challenges that present themselves, you can humanize the experience.

How do you measure the success of your elevator business? Is it enough to look solely at financial indicators? What about your consumers and workers? How do they figure into the equation? Tracking business performance is essential to the success of any organization. It allows businesses to measure their progress, identify areas that need improvement and make informed decisions to achieve their objectives. To capture these aspects, businesses turn to KPIs. These are a set of metrics that organizations use to track and evaluate their performance. By understanding and leveraging KPIs, organizations can build effective scorecards and integrate remote monitoring into their maintenance strategies.

What Are Maintenance KPIs?

Maintenance KPIs are values that can be measured to assess how well maintenance activities are being performed in an elevator operation. This provides insights into the effectiveness, efficiency and reliability of maintenance operations. Common KPIs may include:

- Mean Time Between Failures (MTBF): Average time elapsed between equipment failures. A higher MTBF can indicate greater reliability.

- Mean Time To Repair (MTTR): Average time required to repair a failed component. Having a lower MTTR may reflect quicker recovery and less downtime.

- Overall Equipment Effectiveness: A comprehensive measure of operation performance, asset availability and quality.

- Maintenance Cost as a Percentage of Replacement Asset Value: A ratio that helps evaluate maintenance spending compared to the value of the assets being maintained.

- Percentage of Planned Versus Unplanned Maintenance: The ratio of scheduled maintenance versus unscheduled. A higher percentage of planned maintenance may indicate solid planning and fewer unexpected breakdowns.

Building a Maintenance Scorecard

A maintenance scorecard is a tool that consolidates multiple KPIs into one, comprehensive view of maintenance performance. Building a maintenance scorecard can be as straightforward or as complex as you make it. This depends on several factors, including the scope of maintenance activities, complexity of the managed assets and the level of detail accounted for. Here’s a breakdown of the process and some challenges you might encounter:

- Identify Relevant KPIs: Select KPIs that align with the maintenance goals and operational priorities in your elevator business. You should consider factors like equipment criticality, operational objectives and industry standards.

- Set Targets and Benchmarks: Establish realistic, achievable targets for each KPI. Benchmark these targets against industry standards and your own business aspirations. Get your managers involved in developing these KPIs so they can be a part of the solution.

- Collect and Analyze Data: Implement systems to gather data for each KPI. This may involve manual tracking, automated data collection or a combination of both. Analyze the data to identify trends, areas for improvement and successes. My recommendation is, at minimum, a weekly review with management.

- Visualize Performance: Use charts, graphs and dashboards to present KPI data in a clear and actionable format. This visualization can help stakeholders quickly grasp maintenance performance and areas that may need more attention.

- Review and Adjust: Regularly review the scorecard and adjust your KPIs, targets or processes as needed based on your performance trends, business changes or technological advancements. This is crucial to improving maintenance operations.

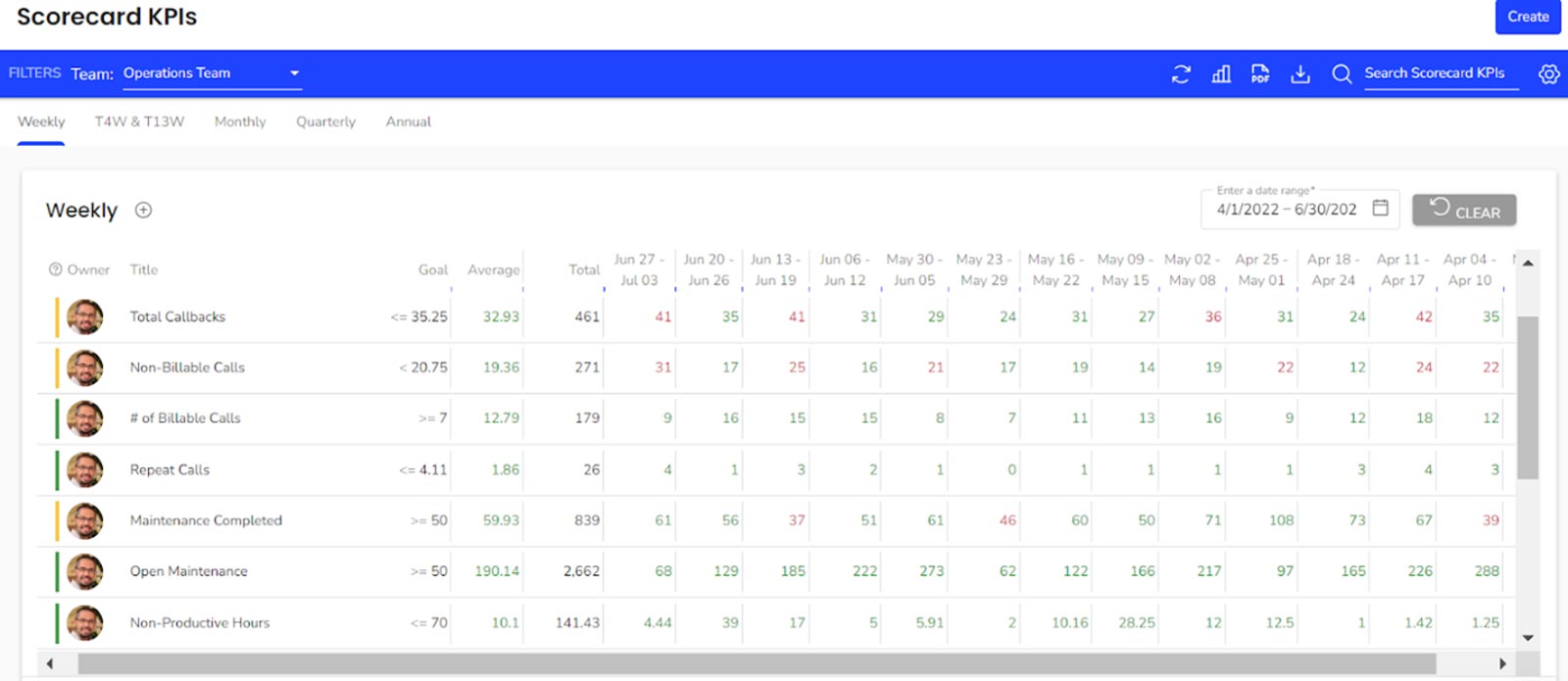

Here are some examples of maintenance scorecard KPIs used at Madden Elevator to track open and completed maintenance, callbacks (total callbacks + separated billable versus non-billable callbacks), repeat callbacks and non-productive hours of field techs. These scorecard KPIs were reviewed, strategized and proactively managed each week in our operations meeting. This systemized process developed by the operations team helped them keep a pulse on what was going on in their services departments. Things happen. This proactive approach gives the operations team a chance to dive into and solve problems early before they become a client issue.

Tying KPIs Into Remote Monitoring and Maintenance

Remote monitoring is transforming maintenance practices by enabling real-time tracking of equipment performance and condition. Integrating your maintenance KPIs with remote monitoring systems may enhance the effectiveness of those strategies, which provide:

- Real-Time Data Access: Remote monitoring provides continuous data on equipment status, enabling real-time tracking of KPIs like those listed above. This allows for a quick determination of issues and swift intervention. Real-time data access can promote more efficiency and effectiveness in your KPIs.

- Predictive Maintenance: By analyzing data trends from remote-monitoring systems, elevator businesses can shift from reactive to predictive maintenance. This approach leverages KPIs to predict potential failures before they occur. This optimizes maintenance schedules and reduces unexpected downtime.

- Enhanced Decision-Making: Remote-monitoring systems typically come with advanced analytics tools that can process large amounts of data. Integrating these insights with KPIs enables more informed decision-making to prioritize maintenance tasks and effectively allocate resources.

- Continuous Improvement: The combination of remote monitoring and KPIs facilitates ongoing performance assessment. Elevator businesses can continuously refine maintenance strategies based on real-time feedback. This can improve your overall efficiency and reduce costs.

- Increased Accountability: By linking KPIs to remote monitoring, elevator businesses can enhance accountability within their maintenance teams. Having clear performance metrics will ensure that your teams are aware of their impact and can be held accountable for achieving their maintenance goals.

Maintenance KPIs are vital for measuring and improving maintenance performance. Building a maintenance scorecard allows an elevator business to consolidate and track KPIs effectively. This provides a comprehensive view of maintenance activities. Integrating these KPIs with remote-monitoring systems can further enhance maintenance practices by enabling real-time data access, predictive maintenance and continuous improvement. By leveraging KPIs and remote monitoring, elevator businesses can achieve greater operational efficiency, reduce their downtime and optimize maintenance strategies to guarantee long-term success.

Yes, I know the term “remote monitoring” has become a bit infuriating in our industry over the last decade. However, there are ways to use the data to augment the services provided by supplying elevator technicians with focused information that allows them to see issues before they cause shutdowns or entrapments. This approach does not reduce or remove the elevator services tech. Rather, it augments their ability to do their jobs more efficiently and effectively for the most important end result: safer, more reliable elevators for our clients and the riding public.

Empowering Elevator Entrepreneurs, Summary

Elevator entrepreneurs, leaders and/or managers should never create scorecard KPIs in a bubble on their own. Utilize your teams! Work closely with them to create KPIs that will promote success in the departments.

KISS, or Keep It Simple and Smart. Start with three to five scorecard KPIs per objective, ensuring you have some leading indicators, some lagging indicators and some macro indicators.

Do not automate these KPIs. It is common for people to want to automate pulling in KPIs. However, this is a mistake. The process of managers pulling data, vetting the data, understanding the data and manually entering the data has a profound physiological effect — making them want to see their KPIs on track. If they are off track, they will want to determine why, then formulate a plan to solve the problem. This process gives them an opportunity to explain a plan of attack to make improvements before the weekly online meeting.

Get more of Elevator World. Sign up for our free e-newsletter.