Mechanical Ramp of Gran Via Vigo

Feb 1, 2021

Top-of-the-line moving walks installed in often-wet urban conditions.

submitted by Helena Calado, thyssenkrupp Elevadores S.L.U.

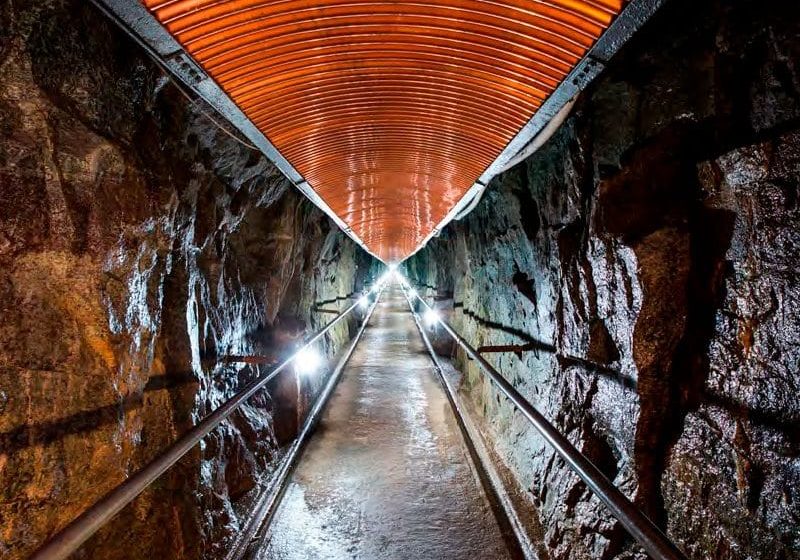

The project “Accessibility Vigo — Rampas Mecanicas Gran Via de Vigo” is a cog within a machine that is “Vertical Vigo,” an ambitious project that aims to improve pedestrian mobility between the lower part of the city and the O Castro Mountain, turning Vigo into a reference in accessibility, and economic and environmental growth. The installation of six moving walks in Gran Via de Vigo, a street emblematic of the city, brought us a little closer to this achievement. With a capacity to transport 6,000-7,300 people/h, it moves passengers under a colorful roof that evokes the area’s characteristic rainbow tones.

Rainfall is prevalent in the city. For the moving walks, stainless-steel exterior coating, drainage solutions and weather-resistant paint were some of the applications to help ensure high quality and durability. To satisfy the demand of the city’s inhabitants, they have an inclination angle of 4.98-5.16º, a length of 9.6-48 m and a pallet width of 1.2 m. In addition, to improve their availability, these units incorporate an INSIGHT remote control and monitoring system with which both the client and company may monitor the moving walks’ condition and provide a quick and efficient response to any equipment incident.

Safety

The units are compliant with EN 115-1, which includes protection:

- Against elongation or breakage of step chains

- Against the reversal of the direction of travel

- Between steps and combs

- Against breakage or deformation of steps and their rollers

- Entrapment at the handrail entrance

- Against an open pit

There are also rollers to eliminate static electricity, handrail synchronization and monitoring, sensors for lack of a step(s)/pallet(s), floor cover locking and brake system monitoring via safety blocking/unblocking.

Technology

The units are equipped with frequency converters, which allows a unit to operate at a speed of 0.2 m/s when it does not have passengers. This saves energy, as do the white LEDs used as under-balustrade illumination. thyssenkrupp Elevator’s predictive-maintenance system, MAX, will also be implemented, and diagnostic display indicates the reason for a stop. A series of pairs of transmitter-receiver photocells on each side of the tread/pallet band form a photoelectric barrier that detects the presence of people along the staircase. This system is mainly used for remote operation, allowing stopping and starting without the need to verify the presence of people in situ.

Extra features to cope with the outdoor conditions include:

- A drain placed in the lower head

- An oil separator in both heads

- An epoxy-type paint for the structure

- IP65 motor protection

- Stainless-steel exterior screws and handrail guide

- Pallets with waterproof bearings

- Electrical conductions and microswitches with IP54 protection

- Automatic lubrication

- Chain protection

Two-color traffic lights on both heads of the skirting board are used to indicate the direction of the unit’s movement, and microswitches stop the escalator as soon as an object enters the space between the steps and socket. Other technology includes:

- Covers for access to the intermediate support (where applicable)

- Anti-static rollers

- Thermostat control during operation

- One stop key and one local/remote key

- 2RS rollers

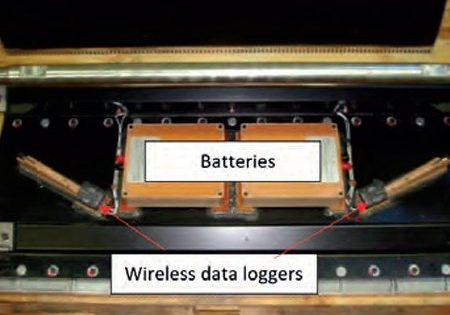

- Tramex moisture meters in upper pit

- Plastic protection for the stop

- Reinforced handrail drives with openwork rollers (instead of Poly V® belt drives)

- Automatic restart after voltage drop

Installation

An elaborate installation plan was made involving meticulous coordination with our client. The client’s objective was to confront the challenges of work in the middle of the city center, where road traffic, passersby and structure accesses were disturbed as little as possible. Once it was determined that the work would be performed during the daytime, the sections of the truss were lowered using a 60-80-mT crane. This crane was also used to assemble and connect the sections in the pit. The whole of this operation was carried out on the same day for each corridor. It was necessary to move the crane, depending on the sections to be assembled.

Despite the challenges of working amid the pandemic, we completed the installation quicker than planned, in September 2020.

Get more of Elevator World. Sign up for our free e-newsletter.