In February, Mitsubishi Electric Corp. announced a new line of technologies that enables ultra-high-speed elevators to travel faster than 1,000 mpm with enhanced efficiency, comfort and safety. The technologies will be incorporated into some of the world’s fastest elevators, including those developed by Mitsubishi for the 632-m Shanghai Tower under construction in Shanghai. Mitsubishi Electric’s advanced solutions incorporate technologies and equipment for enhanced drive and controllability, safety, super-high-rise cable mechanics and passenger comfort.

Drive and Controllability:

- The traction motor incorporates a permanent magnetic motor for energy-efficient, low-noise, low-vibration operation.

- A single motor has two grouped three-phase winding coils and parallel drive systems controlled by separate control panels. Each motor has a built-in converter to regenerate electricity, lowering power consumption by more than 30%.

Safety:

- Safety gears, which activate the brakes by grasping the guide rails in emergencies if cables become transected, comprise two stages to manage increased kinetic energy due to ultra-high speeds.

- Fine ceramic is used for the safety-gear shoe to realize high resistance to heat, abrasion and shock. Braking is extra stable, even if high frictional heat is generated when the safety gear is activated.

- The hydraulic oil buffer (shock absorber) at the bottom of the elevator shaft has an advanced plunger comprising three stages for exceptional shock absorption within a shortened frame.

- Newly developed governor monitors elevator speed stability, even with heavy loads placed by ropes traveling at high speeds over long distances.

Super high-rise cable mechanics:

- A steel core with a wider diameter provides high intensity, allowing traveling cables to be lightened by using lightweight sheath material and operated by a highly efficient electric carrier system.

- Mitsubishi Electric’s sfleX-rope comprising bundles of high-intensity steel wire strands, each covered with plastic, offers higher intensity and density, and wider cross-sectional area than conventional rope, which helps reduce rope stretching caused when passengers step into the elevator.

Ride comfort:

A new active roller guide, which reduces vibration from the guide rails and wind, enhances passenger comfort, even at ultra-high speeds.

- The inside of the car is extra quiet thanks to a streamlined aerodynamic car cover and an insulated cage.

- Air-pressure control helps minimize rapid changes in atmospheric pressure for reduced ear discomfort.

For more information, contact Mitsubishi Electric’s Overseas Marketing Division, Building Systems Group at e-mail: [email protected] or website: www.mitsubishi-elevator.com.

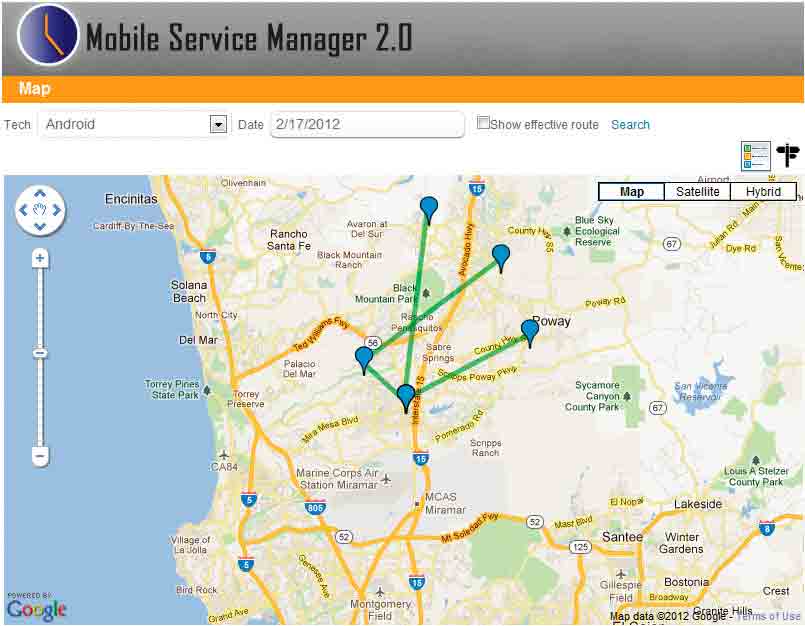

Mobile Service 2.0

Expert Service Solutions, Inc. recently released its Mobile Service 2.0 multi-platform application for iPhone, iPad (iOS) and Android devices. Designed to support field operations, Mobile Service provides instant access to pending service calls and route information (ELEVATOR WORLD, November 2008). It allows workers to log time spent, materials used, equipment worked on, complete work description and capture customer signatures. Once the information is captured, it is sent to the company’s Mobile Service Manager, which displays the status of each job at any time. Mobile Service provides a paperless solution allowing customers to access timely, accurate information and eliminate redundancies. Companies can access real-time information on the status of any job and location of field members with a GPS mapping solution.

For more information, contact Expert Service Solutions at phone: (888) 596-9481, fax: (415) 532-1859, e-mail: [email protected] or website: www.expertservicesolutions.com.

Sound View Electronics’ Escalator Speakers

Sound View Electronics, manufacturer of automated messaging systems for escalators and moving walks, has announced a new addition to its product line. The new low-profile seamless stainless-steel speakers are only 1.3 in. high, 64% shorter than the company’s existing center-mount speakers, making them among the lowest in the industry, while still capable of providing quality audio. The design of the low-profile model allows the speakers to be installed entirely from the top.

In addition to these speakers, Sound View continues to offer its center-, side- and flush-mount speakers. Once installed, they are connected to a solid-state amplification system housed in a National Electrical Manufacturers Association-approved enclosure typically mounted in the escalator pit or motor room. Speakers are designed to withstand shock, impact and vibration. All messages are professionally recorded, can be changed and reloaded when necessary and can play continuously or be triggered by motion sensors detecting the presence of passengers.

For more information, contact Sound View at One Hollywood Avenue, Suite 6, Ho-Ho-Kus, New Jersey 07423; phone: (201) 444-4782; fax: (201) 701-0442; e-mail: [email protected]; or website: www.soundviewelectronics.com.

Oil Smart Elevator Alarm System

SEE Water, Inc. is an Underwriters Laboratories/Industrial Control Panels 508-approved designer and manufacturer of water pump controls, high-liquid alarms, and pump control panels, with a primary focus on the design of Oil Smart® technology. This technology can differentiate between oil and water, will automatically pump water without the risk of pumping oil into the environment and give an alert in the event of an oil spill.

The company’s new Oil Smart Elevator Alarm is a plug-and-play alarm that includes visible mounted indicators and dry contacts for remote monitoring. A combination optic and capacitive unit, the alarm activates in the presence of liquid and identifies if oil or water is present, making the system suitable for high-liquid alarm or leak detection system. Units are available as a standalone alarm or in a complete Oil Smart Pump and Alarm System. Standalone models include the OSA-05 alarm for plug-and-play capabilities and the OSA-06 for hardwiring.

For more information, contact SEE Water at 121 North Dillon Street, San Jacinto, California 92583; toll free: (888) 733-9283; phone: (951) 487-8073; fax: (951) 487-0557; e-mail: [email protected]; or website: www.seewaterinc.com.

Maxton Coil Cover Design

Maxton Manufacturing Co. has released its new control-valve coil cover design for the UC1/UC1A/UC2/UC2A hydraulic elevator control-valve series. The product is a complete retrofit, using the old base plate from an approved fire-resistant, high-impact material with improved labeling and pressed-in metal insert, which replaces the washer used in fastening the cover to the valve. A new bracket completes the coil enclosure and provides electrical-wiring access and connection replacing the previous control-valve base plate.

The normal function of the coil cover is to protect coils and encase electrical activity, preventing shock. The new design provides a better form, fit, function and noise- level reduction, and larger labeling area.

For more information, contact Maxton at 1728 Orbit Way, Minden, Nevada 89423; phone: (775) 782-1700; or website: www.maxtonvalve.com.

Get more of Elevator World. Sign up for our free e-newsletter.