Moffatt Machinery Manufacturing Co.

Jun 1, 2015

Self-sufficient Charlotte, N.C., company possessed remarkable business model.

One of the most familiar sayings about curiosity reminds us that the last place we tend to look for something interesting is “in our own backyard.” A recent invitation to examine a hand-powered elevator located in Fairmont, North Carolina, prompted the investigation of an elevator manufacturer that operated in Charlotte, North Carolina, during the opening decades of the 20th century. Because your humble elevator historian is on the faculty of the University of North Carolina at Charlotte, this provided the impetus to (at last) begin to study the history of local elevator manufacturing. While this examination marks your author’s first foray into his own “backyard,” it will not be his last.

On May 2, 1905, the local Charlotte press reported that a charter had been issued for Moffatt Machinery Manufacturing Co. and that the new company had a starting capital of US$100,000. The company’s board of directors was announced on May 21 and included W. Erskine Moffatt (1855-1929), Zebulon V. Kendrick (1864-1953), John G. Baird, John H. McAden and E. Randolph Preston. Interestingly, only two on the board had a direct connection with manufacturing: Moffatt was described as “one of the most practical and progressive men today in the Southern mechanical world,” and Kendrick was characterized as being “known to the people of the county as a leading mechanic.” In 1895, Moffatt had been a cofounder of Park Manufacturing Co., which began to build elevators in 1902 (this company, still in existence, will be the subject of a future article), and Kendrick had been a manager at the Charlotte Pipe Foundry. The other directors were well-known local businessmen and investors.

The primary focus of the new company was described as the manufacture of “elevators and heating pumps.” This focus reflected Moffatt’s earlier career: he held two patents on improved pumps and had almost three years of experience building elevators at Park Manufacturing. The issue of Moffatt’s patents is of interest, because a November 17, 1905, article in the Charlotte Observer claimed he held “special patents” on both heating plants and elevators, which were characterized as “superior to any others on the market today.” However, thus far, no elevator patents produced by Moffatt or his company have been found. The reporter may have misunderstood the extent of Moffatt’s patent record, or he may have simply been engaged in hyperbole about a hometown enterprise.

On May 22, 1905, the local press reported that the company hoped to begin operations in early August. This was a bold statement, given that no factory existed to support the business. This concern was addressed on May 24th, when ground was broken for a new building. In June the national trade journal The Iron Age announced the following progress:

“Orders for machine shop, pattern shop and foundry equipment will be placed about June 25 by the Moffatt Machinery Co., Charlotte, for equipping its new plant. The company has thus far placed orders for a few of the tools and for the electric power plant. . . . The main building will be 60 X 240 ft., on either side of which will be erected the foundry and blacksmiths’ shops.”

On July 31, the Charlotte Observer provided an extensive account of the building’s construction:

“The foundation for this extensive plant is laid in concrete to the height of the windows. . . . The work has been done by the company under the supervision of Mr. W.E. Moffatt, president and general manager for the company. The walls from the windows up are being made of the celebrated Catawba brick, laid in red mortar. . . . Already, the machinery for equipment is beginning to arrive. The Catawba Power Co. has completed the wiring and a 25-hp motor has been installed, by means of which the company is planing, sawing and making window frames, cross beams, rafters, etc. to be used in the construction of the building. . . . Mr. J.G. Baird, secretary and treasurer, informs an Observer man that quite a number of large orders are now awaiting the completion of the plant. Unless hindered, the plant will begin operations by September 1st.”

The fact that Moffatt was overseeing the construction and that company employees were doing the work speaks to a business model and self-sufficiency that is remarkable by today’s standards. Although the reasons for the delay are unknown, Moffatt missed the projected September deadline, and the factory was not completed until mid November. Nonetheless, between May 24 and November 17 1905 — roughly six months — Moffatt built a 20,400-sq.-ft. factory comprised of a main building (60 X 240 ft.), which housed machine and wood shops, and an adjacent foundry (60 X 100 ft.).

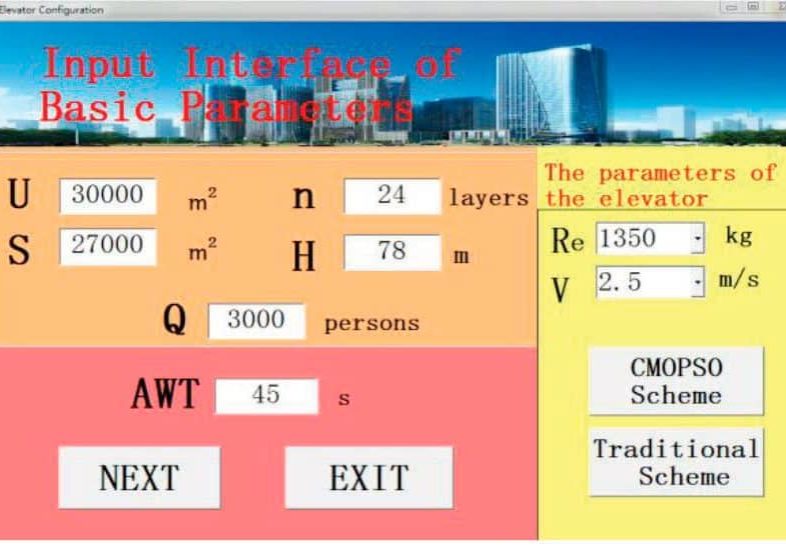

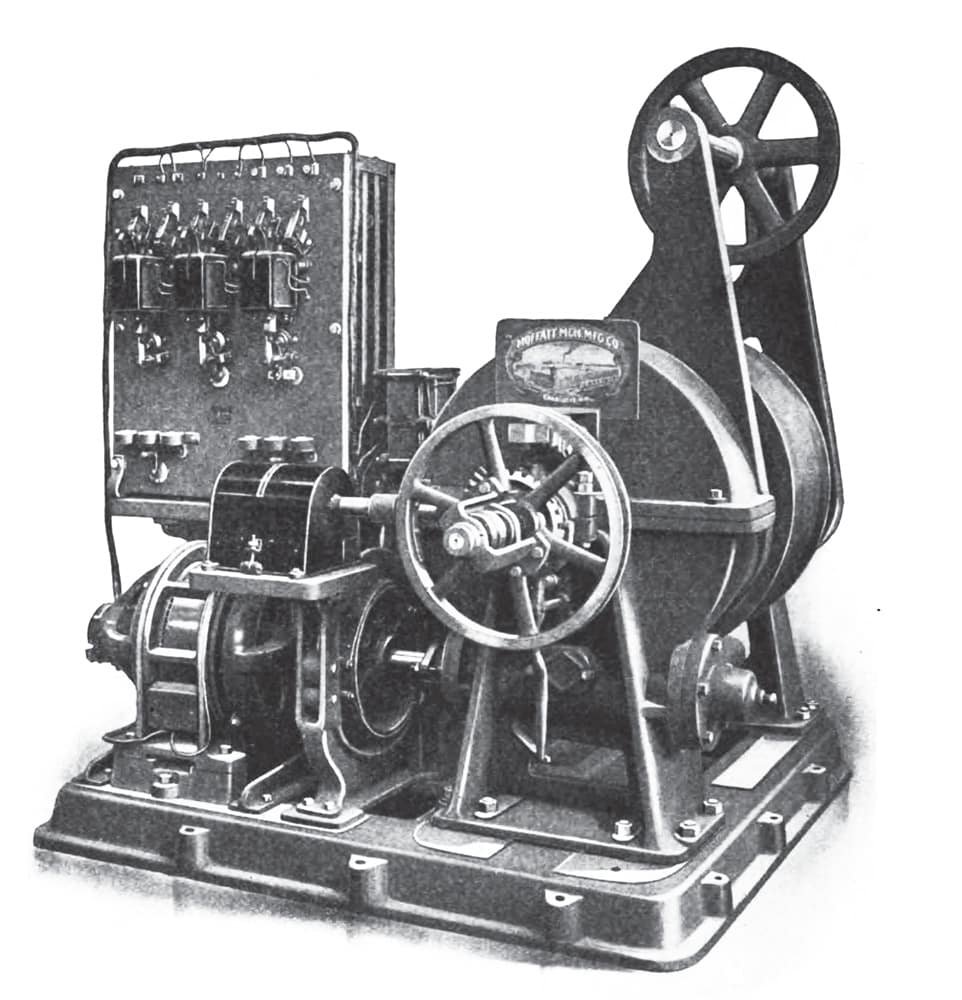

As had been reported in the past, the “specialties of the Moffatt Manufacturing Co.” were to be “heating plants and elevators, both hand and power driven.” This brief statement offered the first hint that the company intended to manufacture a range of elevator types. This was confirmed in a two-page illustrated advertisement that appeared in the 1911 edition of Sweet’s Catalog of Building Construction. The advertisement depicted and briefly described Moffatt’s direct-connected electric passenger and freight elevators, which were available as DC or AC drum machines. The winding drums featured “heavy double arms grooved for cable, machine cut,” an automatic stopping device that was “guaranteed never to slip” and “loose pulleys” that included Moffatt’s “centrifugal grease cups.” Their passenger machines were “equipped with either full mechanical, semi-mechanical or full magnet control, with speed governor and the best safety appliance that is known to make elevator travel safe.” The motors were described as “wound especially for hard elevator service” (Figure 1). In addition to electric elevators, Moffatt also built compound and direct-piston hydraulic elevators, sidewalk and ash hoists, hand-powered elevators, automatic doors and gates, cars and shaft enclosures. The company’s claim regarding the latter two items reflected a rather pragmatic attitude: “We furnish all classes of elevator cabs and enclosures, from the most elaborate to the plainest and cheapest to be had.”

The same attitude was also expressed by Moffatt in a lengthy article on the company that appeared in the February 1, 1914, issue of the Charlotte News. One focus of the article was the challenge faced by local businesses when they competed with national companies. Moffatt stated he had “received contracts from Southern buyers mainly because ours is a Southern enterprise, and they prefer to do business with Southern men, when the price and quality are the same” as products offered by Northern competitors. However, he also noted that a similar collegial commercial spirit was not consistently found in his hometown of Charlotte. The article reported that much of Moffatt’s success was due to his marketing efforts throughout the South: by 1914, he had built elevators for buildings located in Jacksonville; Atlanta; Columbia, South Carolina; Birmingham, Alabama; Norfolk, Virginia; and St. Louis.

A survey of Charlotte city directories from 1905 to 1914 reveals that Otis maintained an office in Charlotte. While this is, perhaps, not surprising, two other “Northern” companies also appeared in Charlotte directories during this period: Warsaw Elevator Co. (Warsaw, New York) and Cohoes Iron Foundry & Machine Co. (Cohoes, New York). These companies appeared in the directories under the heading “Elevators.” It is somewhat surprising that neither Park Manufacturing nor Moffatt Machinery Manufacturing was listed in this category during this period. Moffatt’s company did not make its directory debut until 1920, and Park Manufacturing did not appear until 1923. However, by 1916, Moffat was consistently advertising in the local newspapers.

The 1914 article also addressed some of Moffat’s products and his manufacturing processes. He was credited as being “among the first to install electric elevators” in the South. And, although his firm was capable of building high-speed electric elevators that transported “passengers to dizzying heights at the rate of 600 fpm,” the firm did not “specialize” in this type. In fact, according to the article’s author, “the Southern trade does not demand this style of car, and the Moffatt style has become the safe and sane construction [choice], which shall at once be thoroughly durable and very simple.”

Moffatt Machinery Manufacturing stated that simplicity was the key to its elevator design:

“To reduce the machinery product to its simplest form and yet retain its effectiveness is our consistent policy. We are always experimenting on new constructions which shall meet all the requirements of the highly finished machine. . . . It is our aim to make one wheel do the work that has been done by two and yet keep the whole machine as thoroughly safe as when numbers of wheels are used. This is the trend of modern manufacturing principles. Simplify the machine by making the use of the least possible raw material and the elimination of all unnecessary parts.”

Moffatt concluded his remarks with a statement claiming that it was these same ideas that had made a Henry Ford a successful businessman.

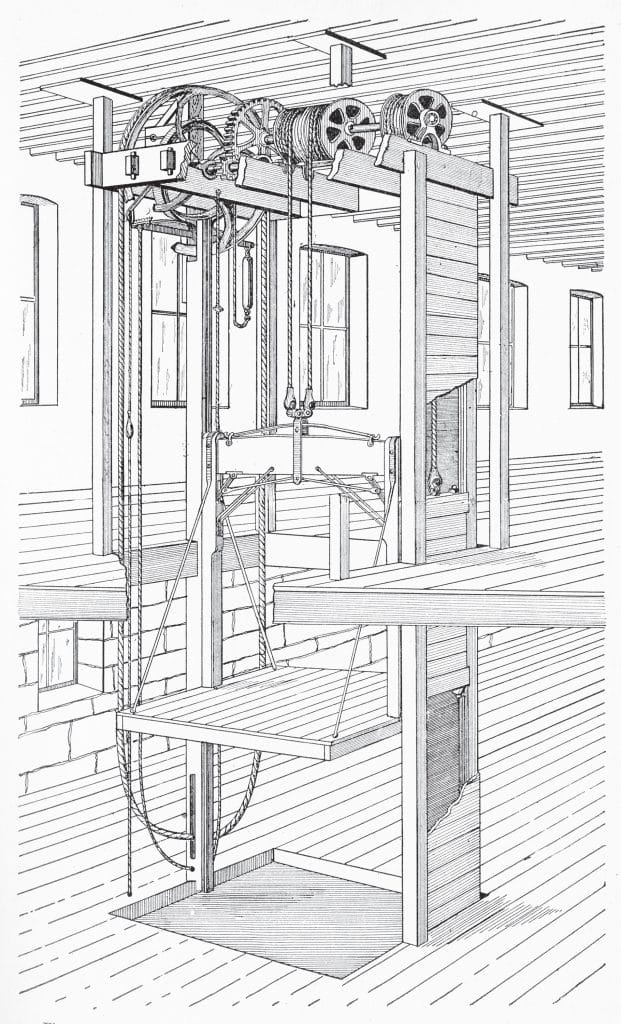

The elevator that prompted this investigation exemplifies Moffatt’s straightforward approach to elevator design and manufacturing. The elevator in question is a hand-powered machine located in a two-story commercial building, which was built in the early 1900s. The elevator is no longer operational and has been secured to the second floor such that the top of platform is not visible. Its hoisting mechanism has been reduced to four primary components: a large hoisting sheave, a driveshaft fitted with a pinion gear, a combination bevel gear friction sheave, and a small counterweight sheave (Figures 2 and 3). The drive shaft is connected to the hoisting sheave such that, as it turns, the pinion gear meshes with the bevel gear of the friction sheave, and the car rises or falls (depending on the direction of the hoisting sheave’s movement). The single hoisting cable is attached to top of the car, and the counterweight and passes around the V-shaped groove of the bevel gear friction sheave. The hoisting sheave is equipped with a typical friction brake, and the crossbeam contains (on both sides) a color image of the company logo that depicts the factory in Charlotte (Figures 4 and 5). The simplicity of Moffatt’s design is reinforced when compared to a typical hand-powered drum machine (Figure 6).

Moffatt Machinery Manufacturing remained in operation until 1932, closing three years after Moffatt’s death. Although it had a short-lived existence, its dynamic founder created a distinctly Southern company that made a substantial impact in the region and, however briefly, effectively challenged larger, more established firms. Your author would like to thank Eric Thompson of Fairmont, North Carolina, for his generosity in sharing his elevator with me. He helpfully provided the opportunity to examine some of the elevator history in your author’s “own backyard,” where he looks forward to pursuing future research.

(l-r) Figures 2 and 3: Hand-powered elevator, Moffatt Machinery Manufacturing

Top to bottom: Figure 4: Detail of hoisting sheave and brake mechanism, hand-powered elevator, Moffatt Machinery Manufacturing; Figure 5: Detail of logo

Figure 6: Typical hand-powered elevator, John S. Jallings, Elevators: A Practical Treatise on the Development and Design of Hand, Belt, Steam, Hydraulic and Electric Elevators (Chicago: American Technical Society, 1917)

Get more of Elevator World. Sign up for our free e-newsletter.