New Accident Potential in Elevators

May 1, 2025

Your author details several cases.

by Anthony Andon

In elevator safety standards, which are more commonly applied in ASME or EN formats, the strength and performance of certain components such as safety brakes, buffers, door locks, door panels, etc., are verified through type approval tests at nominal load and increased speed. However, due to the multitude of other mechanical components, these standards consider them as design assumptions that must be considered by the elevator constructor. In recent years, especially in developing countries where competition to lower final costs is very common, accidents have unfortunately occurred involving components that did not require inspection or documentation review. Some of these cases are detailed here.

Car Sling/Yoke

According to the standard, all main components such as safety brakes, wire ropes, guide shoes, etc., must apply their loads to the car sling/yoke. But is this main structure, which bears all the loads, sufficiently strong? It is obvious that if the car yoke cannot withstand the applied load during safety braking, buffer impact or sudden brake stop, it will twist or suffer serious damage, and the possibility of manual emergency rescue of trapped passengers will be lost.

Counterweight Frame

Due to the sudden stop of the cabin caused by safety brakes, buffer impact or sudden motor braking, the reaction force is transferred to the counterweight frame. Unfortunately, frequent cases of twisting and deformation of the counterweight and the exit of the weight from inside it or from the rail have been observed.

Wire Rope Fixing

In suspension systems such as 1:2, 1:4, etc., there is a need to provide a plate for fixing the wire ropes. It is obvious that if it cannot withstand the force caused by the impact, the wire rope may come out.

Motor Baseplate in Machine Room Elevators

Due to the lack of explicit requirements for the motor base, various accidents caused by the fall of the motor during cabin parachuting have been observed. This is due to the lack of profile strength or the creation of large holes for the motor base through air cutting.

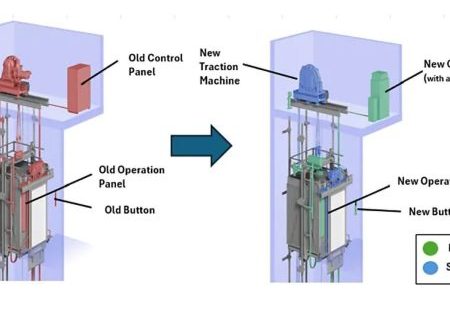

Motor Baseplate in MRL Elevators

In machine-room-less (MRL) elevator design, the lack of strength of the motor base or the use of inappropriate connections to the building structure can lead to a disaster due to the direct fall of the motor (which usually weighs more than 250 kg).

Recommendation

Regarding cases that require proof of structural strength against applied forces, it is recommended to add load simulation through finite element analysis to the standard requirements and include it in the documentation that the manufacturer (elevator constructor) must provide.

Regarding connections, since the components are secured through welding, bolts, rivets, etc., their strength must also be included in the calculations (for bolts and rivets) or a welding inspection report as mandatory documentation.

Get more of Elevator World. Sign up for our free e-newsletter.