New Options for Door Equipment in North America

Apr 1, 2024

Columbia Elevator and USDE join forces to serve VT industry.

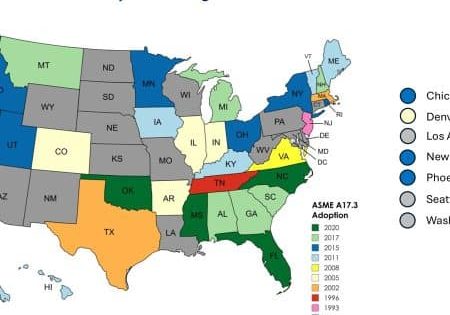

Headquartered in Bridgeport, Connecticut, with manufacturing facilities both there and in Kansas, Columbia Elevator has been a well-known and respected provider of elevator cabs, entrances and doors for nearly 60 years. Now, partnering with US Door Equipment Corp. (USDE), a greenfield investment and autonomous entity of Fermator solely dedicated to serving the North American (NA) market, Columbia is offering complete door systems and more to the open market. USDE opened its 140,000-ft2 factory in Oxford, Connecticut (approximately 22 mi north of Bridgeport), in 2021. The facility has an annual capacity of 55,000 complete door systems. It is here where Columbia and USDE co-design and manufacture several elevator door products via its combined platform for the NA market. “We aim to be a technology provider and one-stop-shop for door systems and cabs,” says Columbia President and CEO Louis “L.J.” Blaiotta. Blaiotta and Eduard Gomis, managing partner of USDE, observe the partnership’s core values encompass being technology-, solution-, and value-added-driven; being NA-focused; being privately owned and operated; and, most importantly, 100% customer-oriented. “The hallmark of Columbia is being customer- and service-oriented, which will continue under the joint venture platform,” Blaiotta states. Blaiotta (LB) and Gomis (EG), who had an impressive career with his family’s business, Spain-based Fermator, sat down with your author (TBM) recently for a company presentation and factory tour in Oxford. These responses have been edited for clarity and come, in part, from the presentation.

TBM: What are the advantages of this new alliance?

LB and EG: NA customers can now get a complete door system powered by the latest state-of-the-art door-equipment technology for the commercial, limited use/limited application (LU/LA) and home elevator segments, as well as doors with narrow and slim footprints. Born and raised in Spain with an extensive global presence, Gomis’ 20-plus years of knowhow and R&D capability in the elevator door industry pairs USDE door equipment technology, i.e., landing mechanisms and door operators, with Columbia’s field-proven entrances and UL-certified cabs.

The alliance also results in a common platform for independents and highly efficient and modern manufacturing supported by global sourcing. From three manufacturing facilities across NA, Columbia and USDE can accommodate everything from highly customized jobs in Columbia’s Northeast or Midwest facilities to large-scale, high-volume orders in USDE’s Connecticut production facility.

TBM: Describe Columbia’s and USDE’s broad physical presence.

LB and EG: In addition to USDE’s Oxford facility where we are now, Columbia has a 35,000-ft2 cab and cab interior manufacturing facility in Bridgeport, Connecticut; a 100,000-ft2 facility in Winfield, Kansas, for manufacturing standard and custom entrances; and an engineering and sales office in Miramar, Florida. USDE’s Oxford factory has 120,000-ft2 of production area where a full range of door solutions are designed, engineered and manufactured to meet domestic standards for both new construction and modernization. The plant has full mechanical testing capabilities including the 5,000 N test and sill-loading test. There is a full assembly line for car door operators and landing mechanisms, an automatic painting line and a fully automated punch-laser cell tied directly into a Night Train warehouse system capable of through-the-night, “lights-out” manufacturing.

TBM: Remind readers a little about Columbia’s background and capabilities.

LB: My father, Lou Blaiotta Sr., founded Columbia in 1965 to service the custom architectural product needs of the U.S. elevator market. We offer a full range of UL-certified cabs and UL-labeled openings up to 14 ft tall and 14 ft wide. We’re a proven provider of customized, engineered projects where our years of design experience can be applied.

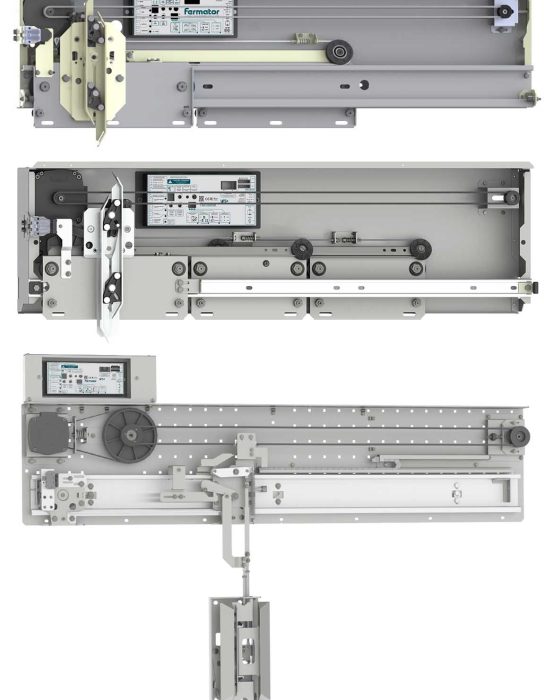

TBM: Describe the new USDE door equipment products that can now be bundled with Columbia’s architectural products, and this partnership.

LB: New to the U.S. market are the three products we build here at USDE’s Oxford facility. We have Robusta, a complete line of door equipment tailored to fit traditional NA sizing, making it suitable for heavy-duty, new installations and ideal for modernizations. For the new-installation market, our slimline Premium NA door systems optimize shaft space for commercial and LU/LA installations, while our 4010 product line delivers a fully automatic door solution to the home elevator market. By partnering with USDE, we’re bringing their global supply chain expertise to the NA market and working together to adapt these products for the NA market and local manufacturing. During COVID, we went through every one of these products and said, “This won’t work or this will, specific to the needs and preferences of the NA market, or we have to tweak this and make it American.”

You’ve known us for 60 years for our cabs, doors and entrances. But now, for the first time ever, we can support the independents with a complete door system. Together with USDE, we’re becoming a solution provider, and a one-stop shop of complete door systems. In addition, we are expanding our product range. We can now offer narrow and slim doors, which provide a desired option that was never available to independent customers in NA. Under the common platform of Columbia and USDE, independent customers now have more options, ranging from everything they used to get from Columbia to doors and entrances with small footprints to complete door systems with proven door equipment. It is a one-stop shop, both logistically and technologically.

Before USDE, I was effectively a distributor for Eduard’s product in NA. What’s completely different now is that we are partners with a combined platform, starting from design and engineering. This enables us to introduce new options — with U.S. roots and proudly manufactured in the U.S. — to the NA market. The combined platform also makes us more competitive by taking out extra layers. Instead, we let our customers enjoy the most cost benefits. We like to be known for the high quality and performance of our products, as well as being the best value. For Columbia, the partnership with USDE is organic, with us being privately owned and sharing the same mindset of providing our customers the best value and service. I believe that our customer base will see and enjoy the benefits of this partnership.

Under the common platform of Columbia and USDE, independent customers now have more options, ranging from everything they used to get from Columbia to doors and entrances with small footprints to complete door systems with proven door equipment.

— Columbia Elevator President and CEO L.J. Blaiotta

TBM: Does USDE have any plans to do complete elevator systems?

EG: No. An elevator is a complex system, and it’s challenging to be good at every part of it. Our core competence and focus are elevator door systems.

TBM: Through major acquisitions and production facilities and partnerships around the world, Fermator enjoyed tremendous growth, most of which happened under your leadership. What is the relationship between Fermator and USDE?

EG: USDE is completely autonomous. When Fermator starting thinking about becoming present in the U.S., we decided to build an independent platform with resources, technology and products solely dedicated to the NA market. All Fermator products for the NA market have been reengineered for USDE in conjunction with Columbia, and will be exclusively served by USDE moving forward.

TBM: Does USDE have trouble finding good skilled employees?

EG: Since we started in 2019, it’s been tough. The pandemic made it especially tough. However, we were fortunate to develop a core team who have been with us from the beginning. We truly believe that investing in and building our own team is the best way to acquire and retain talent. The team has come together slowly but surely. And we will always be actively looking for and welcome new talent to upgrade and expand.

TBM: What are your plans for the perpetuity of USDE in the future?

EG: Our audacious goal is to become the leading and preferred manufacturer of elevator doors systems and cabs in the NA market. Beyond the obvious synergy of the partnership with Columbia, it’s all about technology, people and the ability to execute. Technology, because the NA market is both conservative and demanding. I see USDE as a technology company at its core. We focus on the things that provide our customers with added value and more options from which they can freely choose, whether it’s an installation method, integration, lighter equipment, etc. USDE, together with Columbia, is a platform that will bring in more core and new technology in door systems and beyond. Together, we look forward to growing our customer base and seeing what the future will bring.

Get more of Elevator World. Sign up for our free e-newsletter.