Oleo International

Mar 1, 2015

World’s largest elevator buffer just the latest in innovations from British company

Oleo International, a company specialising in crash energy management systems, designs, manufactures and supplies products across multiple sectors worldwide, focusing on the elevator, railway and industrial markets. The firm employs 265 worldwide, with 220 based in Coventry, U.K. With other operations in China, Germany, the U.S. and an office in India, Oleo exports 95% of its products and supplies its buffer range to all leading elevator manufacturers.

Oleo credits its success to how well it knows its product and the markets around the world in which it participates, and its investment in people, processes and British engineering.

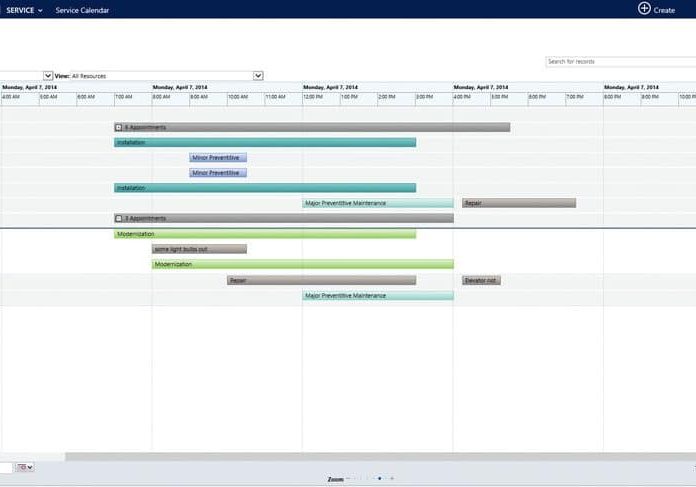

After two years of R&D and an investment in excess of GBP1.5 million (US$2.36 billion), the company has had its HSL 115 and HSL 72 high-speed elevator buffers certified to industry standards EN 81-1/2:1998 and GB 7588-2003. This means the products are now available worldwide. Oleo reported that, as of November 2014, it had already received orders in excess of GBP1 million (US$1.57 million) for these products. They are currently undergoing testing at the company’s 33-m-tall test tower in Coventry, U.K., which it calls “the largest such facility in the world” (ELEVATOR WORLD, May 2014).

Intended as an enabling technology for the installation of high-speed elevators in ultra-high-rise buildings, Oleo’s HSL range is available in multistage heights and is compatible with elevator speeds of up to 20 mps. The buffers (positioned at the bottom of elevator shafts) are designed to provide a vital safety mechanism for elevator systems. While Oleo had already designed, manufactured and installed buffers supporting elevator speeds of 11.62 mps, technology to cope with speeds in excess of 20 mps had not been available.

Oleo described the need for such products thusly:

“While China is the world elevator and new high-rise-building market leader, an increase in the construction of skyscrapers is taking place in many other countries. At the same time, building managers require faster elevators to enable efficient movement of larger numbers of people around these vast buildings. After identifying this global demand for these larger-scale safety-critical products, we developed a new telescopic elevator buffer designed to be used at such high speeds and still be capable of safe average deceleration of 1 G.”

Oleo’s latest elevator buffer range has been driven by market demand from developing countries. The certification comes at a time when other companies in the industry have also pushed the boundaries – notably, KONE with the introduction of its UltraRope (ELEVATOR WORLD, August 2013) and Hitachi, which is installing what is to be the world’s fastest elevator at the CTF Finance Centre in Guangzhou, China (EW, June 2014), to be completed in 2016. Though companies in Asia also produce elevator buffers, Oleo feels it has the advantage of more engineering experience and a uniquely performing product.

Oleo’s latest elevator buffer range has been driven by market demand from developing countries.

Internationally, Oleo has an office and manufacturing facility in China, an office and service center in Germany, a distribution center in the U.S. and a sales office in India. Servicing on its products is performed by local shops it certifies. In 2014, it announced that Lift Solutions Inc. will provide its sales and technical support in the U.S. and Canada (EW, December 2014). T.A. Savery & Co. Ltd., trading as Oleo International, is accredited in accordance with ISO/IEC 17025:2005 general requirements for the competence of testing and calibration laboratories. Oleo International is a U.K. Accreditation Service-accredited testing laboratory (number 7778). The schedule of accreditation, which bears the same accreditation number, is available at www.ukas.com. It can test its own products and those of other companies at this laboratory (EW, June 2014). Additionally, the company’s buffer certification and approvals include EN 81.1, ASME A17.1, GB 7588 and EK 1002.

History, Philosophy and Organization

Oleo International’s history begins in 1934, when cofounder Peter Thornhill developed an undercarriage strut using a free-floating piston. This breakthrough led to the Oleo rail buffer, a product the company still manufactures and exports today. After many years of R&D for a hydraulic railroad buffer, Thornhill lodged a patent in 1951 for the first practical design for a self-contained hydraulic buffer for railroad rolling stock. In 1952, he established Oleo Pneumatics Ltd. under the entrepreneurial influence of fellow cofounder Jack Onions.

By 1960, Oleo was supplying 1,000 hydraulic buffers to British Rail every week. In 1971, the company realized the potential for the product to be used in the industrial market. By 1976, it had developed its primary range of industrial buffers. Shortly after the opening of a new 10,000-m2 manufacturing facility that year, the company expanded its buffer range further when it introduced its lightweight range of elevator buffers.

Oleo credits its success to how well it knows its product and the markets around the world in which it participates, and its investment in people, processes and British engineering. Its thorough apprenticeship program promotes the company’s philosophy of developing staff for long-term careers at Oleo. It also heavily funds R&D to develop crash energy management solutions to make a significant safety difference in multiple global markets and industries.

TA Savery Group acquired Oleo in 2009. The group also includes Savery Hydraulics, a leading expert in the design and manufacture of hydraulic solutions, including large bespoke systems, electrohydraulic control systems and small individual units.

Get more of Elevator World. Sign up for our free e-newsletter.