Once in a Lifetime

Aug 1, 2019

EW gets an inside look at the VT system that will serve a skyline-defining NYC supertall.

Photos by John Dimaio

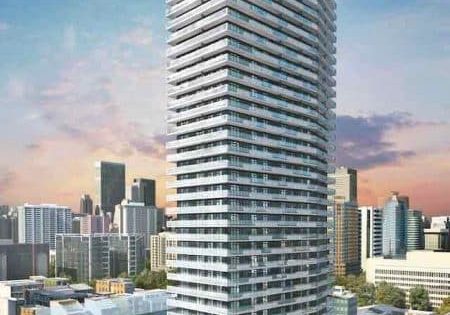

Like a maestro, Kohn Pedersen Fox (KPF) architect James von Klemperer animatedly draws in the air with his index finger to paint a picture of One Vanderbilt, a new supertall rising next to Grand Central Station in Midtown Manhattan. “You can sketch it with one, two, three, four, five, six lines, and then there are a lot of complexities within, a lot of refinements,” he said.[1]

One Vanderbilt’s outward simplicity belies an inner complexity of which its Schindler vertical-transportation (VT) system (ELEVATOR WORLD, June 2018) is a key part. The skyscraper, which will be the tallest office building in Midtown and a defining characteristic of the NYC skyline — on par with the Empire State and Chrysler buildings — involved engineering and design work that began roughly three years before ground was broken in 2016. It will be served by 43 elevators and five escalators. The equipment is by Schindler: 32 passenger and three service elevators, four hydraulic elevators, two trucklifts and three escalators.

Precise engineering and logistics planning are just as critical for the VT system as they are for any other vital building system. Candace Cooper, Schindler’s One Vanderbilt project manager, said “jumping right in and doing it” would be a disaster. “There is a lot of engineering and planning before it even gets to the installation phase,” she said. When your author visited in April, the Schindler team had been onsite for about nine months. Donning hardhats and bright yellow safety vests, she, photographer John Dimiao and Matt Jackson, whose company, Diversified Elevator Products, LLC, represents clients including Brugg Lifting, which is supplying hoist ropes for the project, were guided through the building by Cooper, Schindler Field Superintendent Pat Dineen and External Communications Manager Kim Hoskins.

As steel climbs up One Vanderbilt’s exterior, the Schindler team follows within at a slower (but very involved) pace.

Weeks before the team even arrived, crews were in the building doing what’s called spotting — laying out the templates for the elevator banks and machine rooms. At that point, there was only one machine room in which to work, and Dineen said he was anxious to get started on the others. He said:

“Right now, steel is going up on the building on floors in the 50s. The way the building goes, steel goes up first, followed by the concrete pour. Concrete is usually between five to 10 floors behind, so this is the most developed machine room we can get into (on the 12th floor). Week after next, I’m supposed to start setting my controls, doing all my wiring and getting the machines in here and up and running.”

There will be machine rooms on the 12th floor for the six elevators serving the first 11 floors, the 23rd (low rise), 34th (mid low), 45th (mid high) and 57th (high rise) floors.

Cooper and Dineen consider the machine rooms the brains and heart of any VT system and typically remember their locations long after a job is finished. In April, teams were spotting in the 23rd-floor machine room.

Each of these six elevators serving the first 11 floors will have a 3500-lb capacity and travel speed of up to 1,000 ft/m. Platforms for two of the units were just being finished, allowing us to step onto them and look down into the pits below where counterweight frames had been installed. The cars’ varying sizes and travel heights determine the kind of machines that will power them. “We start out with 560 machines,” he says. “We have 630 machines, and a couple of these are 710 machines — our biggest.”

One double-deck elevator that will be for special use will be mixed into the high-rise bank. It will operate in a double-deck capacity only when an event is being held in the public event space/observatory. With capacity of 3500 lb for each cab, the elevator will have distinct designs for its lower and upper levels, with the upper level matching the look of the event space. Opting for a double-deck elevator saved the developer from needing a dedicated event space/ observation deck elevator.

The 560 machines, which are the majority of the machines, weigh around 12,000 lb and power elevators that travel at 700-1,400 ft/m. The 710 machines are for three high-capacity freight cars, Another view of One Vanderbilt which travel at 1,200 ft/m and have capacities of 6000 lb (two cars) and 3500 lb.

As steel climbs up One Vanderbilt’s exterior, the Schindler team follows within at a slower (but very involved) pace. Other teams follow behind Schindler, which started in the lobby and elevator pits below. Before they were installed, components such as buffers, counterweights, car frames and rails, were stored in the lobby, serving as what’s called a laydown area. When your author was onsite, the laydown area had jumped from the seventh to the 13th floor. “We’ve got no materials left in the lobby, because other crews needed to come in and start doing the stonework,” Dineen said. “I’ve got rails stored up on the 13th floor now, ready to feed to the rest of the building. As the building goes up, we’ll jump those again.”

Apprentices feed the rails up to mechanics who use a capstan hoist to pull them up into place. It’s a precise, measured process that leaves no room for error.

Equations written on walls and beams attest to this.

“You can see it’s written just about everywhere,” Dineen said, continuing:

“We follow a rail-stacking chart based on engineering drawings that make sure we never have a fishplate — a metal bar bolted to the ends of the rails — and a bracket meet. What this does is eliminate problems, such as a wobbly or squeaky ride, caused by irregularly stacked rails. Besides troubleshooting problems before they start, it gets the apprentices involved in thinking a bit ahead instead of just blindly feeding the rails.”

Cooper observed that “you can have the best roller guides and other equipment in the world, but if you don’t install the rails correctly, you’re always going to feel it.”

Skyline Changers

One Vanderbilt is one of many remarkable tall-building tales unfolding in Midtown, including the upcoming largest voluntary demolition ever of the 52-story JPMorgan Chase headquarters at 270 Park Avenue to make way for a new, 70-story building (EW, May 2018) and Central Park Tower, which will be the tallest residential skyscraper in the Western Hemisphere at 131 stories and the skinniest building in the world, at 217 West 57th Street (EW, December 2018).

For One Vanderbilt, Hines is managing the whole project, which includes VT consultant VDA. While most New Yorkers are aware of the dramatic new addition to their skyline, many may be unaware of the “bold, urban initiatives and. . . tribute to the site’s influential past” it represents. In a piece titled “One Vanderbilt: 100 Years in the Making,” KPF states:

“One Vanderbilt continues a legacy of superior design, transit oriented development, and a relationship between the public and private sectors. The prequel to One Vanderbilt’s story began more than 100 years ago with one of the most ambitious undertakings in the history of NYC development. Upon opening in 1913, New York introduced Grand Central Terminal, a marvel of engineering and revolutionary approach to urban development and design.”[2]

Revolutionary though it was, the Grand Central Terminal we know today is the third structure to occupy the site — A Beaux-Arts-inspired design with multiple train lines stacked vertically underneath. Chief Engineer William Wilgus conceived the design, made possible by a transition from steam- and coal-powered locomotives and resulting in “less pollution, direct access to transit and more space and opportunities for development.” One Vanderbilt will be directly connected to Grand Central, which is undergoing a major overhaul itself — part of SL Green’s US$220-million commitment to infrastructure upgrades — that’s part of the project.[2] “Once the commuters come into Grand Central, they’re literally 60 seconds from their office,” Robert Alexander, chairman of the New York Tri-State Region for CBRE Group, Inc., which brokered the deal for SL Green, observed. “You could not ask for a better location.”[3]

Everything we’ve ever designed and practiced and done has influenced this design……………… It will be an unforgettable landmark for New York.” — James von Klemperer, president and design principal, KPF

Boasting an observation deck that may tie for the highest in NYC at 1,100 ft,[4] One Vanderbilt will rise to 58 stories and 1,401 ft, encompassing 1.7 million ft2. For a short time, it will be the city’s second-tallest building behind One World Trade Center. By early 2018, it was more than half leased, with TD Investment Securities, the investment arm of TD Bank; real estate investment trust MFA Financial; and law firm McDermott Will & Emery signing leases.[5] SL Green will occupy 11 floors.

NYC: A Small Elevator World

For Schindler One Vanderbilt Project Manager Candace Cooper, there are babies, and there are babies. First, there are her actual babies — the daughter who was born when she was working on 4 World Trade Center (WTC) and the son she had in May, taking maternity leave from her role at One Vanderbilt. The vertical-transportation projects at the WTC buildings and One Vanderbilt are the other “babies,” said Cooper, who came into the industry after studying mechanical engineering at University of Dayton right after 9/11. Due to a hiring freeze brought about by the economic chaos and uncertainty caused by the events, it would be several years before Cooper’s career would start, but after it did, it launched into full gear and hasn’t stopped since. She said:

“It’s been exciting. These jobs are really part of our lives. For 3 and 4 WTC, I worked with the same Tishman [Realty & Construction] team, so I’ve encountered the same people and formed relationships over time. I worked with Pat [Dineen] on 4 WTC, and I call him the ‘mayor’ of many of these projects.

“This is such a big city, but it’s really small for the elevator industry. For 13-14 years, I worked on projects in Lower Manhattan, and it’s been really neat to come to Midtown and see how we’ve had a hand in changing this skyline. I was pregnant with my daughter when we were doing 4 WTC, and after it was finished, we did a photoshoot with the skyscraper in the background. I’ll probably do the same thing here with my son.”

Cooper’s son will be walking by the time One Vanderbilt opens, which is anticipated in 2021. When your author toured the site, Cooper estimated the VT system was roughly 20% complete. That may not sound like much, but it represents a staggering amount of work the Schindler team had done since arriving in early August. “Just think, six months ago this wasn’t even here,” Dineen says.

The “this” he is referring to encompasses a lot. Involving six massive construction hoists and numerous cranes that carefully transport machines weighing multiple tons, construction was a hive of activity. Car frames were taking shape in what will be the lobby. Fourteen elevator entrances and all the pitwork had been completed. Dineen said the highest point at which his crews were working was the 30th floor, where they were setting up templates and feeding rails.

von Klemperer said:

“Like the Empire State Building and Chrysler Building, it’s one of those delicate moments that comes to one point in the skyline. Everything we’ve ever designed and practiced and done has influenced this design. It’s a great thing to be able to. . . move ahead and prove that New York can be home to the most advanced skyscraper in the world. It will be an unforgettable landmark for New York.” [1]

A Global Effort

The job involved players from all over the country and world. The majority of the equipment is from Schindler: machines from Switzerland, brackets from Vietnam and escalators from North Carolina. Rather than a rope-gripping device, the elevators are outfitted with Schindler’s auxiliary hydraulic brake. [1]

In addition to the Schindler lifts and related equipment, Mongrain Vertical Transport is providing an Americans with Disabilities Act-compliant elevator, a cantilevered hydraulic unit that travels about 4 ft with front and side openings. On the opposite end of the spectrum, size and capacity-wise, Mongrain is providing a pair of 60,000-lb capacity truck lifts, for which deep bore holes were pre drilled. Installation was set to begin in August. Once One Vanderbilt opens, they will be used for all building deliveries, with trucks entering the lifts from 43rd Street. “You can fit a full tractor-trailer on there,” Dineen observed.

At roughly 36ft x 10ft, the double-deck elevator is “huge — a lot bigger than I thought it would be,” Cooper says of a mockup onsite for planning purposes. The mockup elevator had quite a journey before it arrived in NYC. Cooper says:

“The week before Christmas [2018], Schindler Foreman George Kwasniak traveled with another mechanic to Schindler’s factory in Shanghai to oversee construction of a mockup for the double-deck elevator cab. After it was built, they had to get it boxed up and shipped before Chinese New Year [on February 16] so it could get back in time to get us out of the lobby on schedule. So, this only got installed about three weeks ago.”

Elevator Modernization Co. (EMCO) of Capitol Heights, Maryland, is providing cab interiors that will incorporate an impressive array of materials: Corning® Gorilla® Glass on the side walls manufactured by Fairfield, New Jersey-based Galaxy Glass, lightweight white Italian marble stone panels by Atlantic Exterior Wall Systems, light oxidized bronze car operating panels and other metal components and a white aluminum ceiling incorporating three types of LED lighting. Cooper said when she first handled the Gorilla Glass, she had a hard time believing it was glass, as it had the feel and lightness of plastic. Chris Thornhill, senior account executive at Galaxy, shared with EW:

“Developed with the design team at KPF, the glass is composed of Corning’s non-glare, 2-mm Gorilla Glass, which provides a great deal of strength and impact resistance, a bronze-toned, sheer fabric interlayer with a soft, organic quality and a high- quality, ultra-clear mirror. The glass composition was created with both style and utility in mind, as the cab interiors are warm and inviting, yet extremely lightweight and functional.”

The tower’s state-of-the-art elevator cabs are part of a complete package that includes wide, columnless spaces, high ceilings and natural light that reaches into the core of the building. It was designed to the highest Leadership in Energy and Environmental Design certifications and expected to be a “differentiator for recruitment of talent,” according to CBRE NY Tri-State Region CEO Mary Ann Tighe.

For the Schindler team, the ceremonial end of the project will be when the rails are completely installed. Prior to that is the topping-out ceremony, when the final structural beam — typically painted with a fanciful design such as stars and stripes — will be lifted into place after everybody signs it. Cooper says as per tradition, the team will get a half day off to enjoy drinks and food at a neighborhood restaurant. After going home for the day, it will be back to work, at least for a little while. Cooper said:

“We’re scheduled to have a mockup of the passenger elevator sometime in the fall. Once we get all that squared away, then we’ll start bringing those finishes here, and that’s when they will start to look like elevators. Then, we’ll do a punch list after that, and, before you know it, we’ll be turning it over to the client and on to the next job.”

“Our Greatest Achievement”

- “Everyone who has played a major role in this project believes that this is our greatest achievement; truly a once-in-a-lifetime experience.” — KPF President and Design Principal James von Klemperer

- “One Vanderbilt is going to change the energy of Grand Central. It’s going to change the image of Grand Central and reclaim the primacy of this location.” — Mary Ann Tighe, CBRE Group, Inc. New York Tri-State Region CEO

- “It will be the most modern, up-to-date, technologically advanced building in Manhattan when finished.” — Robert Alexander, CBRE chairman, New York Tri-State Region

- “One thing that no one can anticipate until they experience this is what it means to be in a building with no columns, high ceiling heights and glass that enables you not only to see everywhere, but it [also] enables light to enter and go all the way to the core of the building spaces, making you aware of the changing sky and the light of the day. This creates such a different feeling about the arc of the workday, and I think that’s the thing you can’t capture in a rendering. You will experience it profoundly when you’re in the space.” — Tighe

- “One Vanderbilt represents the latest iteration of Manhattan: state-of-the-art technologies, spectacular views and world-class architecture.” — Alexander

- “When you look at the design and the statement it makes on the skyline, you know for sure you’re going to be in one of the top NYC buildings.” — Alexander

- “It really will bring to the heart of a city a structure worthy of what NYC is.” — Tighe

Acknowledgements

Special thanks to Matt Jackson for bringing this project to our attention and arranging the hardhat tour.

References

[1] onevanderbilt.com/design#vid

[2] kpf.com/stories/one-vanderbilt-part-1

[3] onevanderbilt.com/location

[4] Dana Schulz, “One Vanderbilt’s Observation Deck May Tie for Highest in NYC,” 6sqft, November 1, 2017.

[5] Steve Cuozzo, “Four New Leases Planned for Superstructure One Vanderbilt Tower,” New York Post, December 3, 2018

Get more of Elevator World. Sign up for our free e-newsletter.