U.A.E. Ministry of Culture tags area elevator firm for reimagined makeover.

submitted by MASSAED

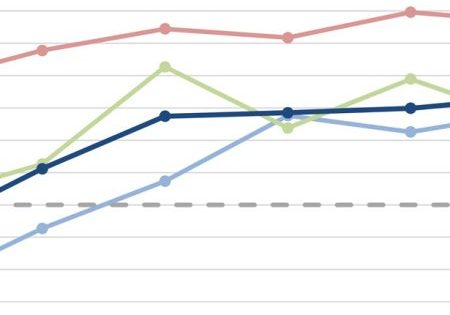

MASSAED Installation of Elevators and Escalators has seen notable growth since its founding in 2008. The company has been engaged in major elevator-installation projects and has achieved significant market share.

One of the company’s more challenging projects was elevator for the Ministry of Culture in Abu Dhabi. Working with its partner, Metron S.A., the company took charge of the governmental site. The Ministry of Culture is seen as the driving force for sustainable growth of U.A.E. culture, fueling economic progress and helping achieve the Emirate’s wider global ambitions.

Aspiring to connect Abu Dhabi to the world on a journey of creativity, the Ministry of Culture is a landmark of authenticity, innovative solutions and creative thought. However, a public sector project means strict adherence to cost estimates, budget controls, quality standards and on-time delivery. One of the most vital issues is people’s interaction with the building, as visitors and employees demand quick, proper operation and reliable elevator service with minimal waiting times, especially during significant spikes in usage.

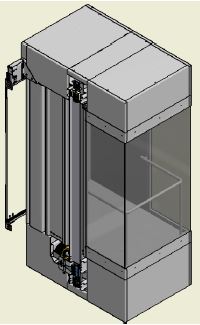

Moving forward with this project, the Ministry sought to change from its old hydraulic panoramic lift to a completely new, cutting-edge elevator. Specifications were set to the highest standards of modern elevators and were pushed by MASSAED knew this project would be a real challenge. The main reasons were the size and shape of the shaft, which had to be kept intact, as it already existed to host the old elevator. That said, it was clear that the shaft was inappropriate for a new traction elevator without a machine-room-less (MRL) motor.

Thus, it was imperative that the design be suitable for a cabin hanging out of the concrete shaft, providing a full panoramic and unobstructed view of the interior space of the Ministry of Culture building. Additionally, the aesthetic view of the elevator should harmonize with the building character; this made it critical that all mechanical equipment be kept hidden. The real challenge was to make it so visitors would see only the panoramic cabin moving up and down, while unattractive wire ropes, car sling and counterweights would be invisible.

End Goal

The concrete shaft width was 2,000 mm, and the shaft depth was limited to 1,200 mm. Based on the available space, a cabin size suitable for 13 persons and a 900-mm center-opening glass door was the ideal solution. Cabin depth was set to 1,850 mm. The cabin is hanging more than 700 mm out of the concrete shaft. It should be noted that this part of the cabin is made only of glass — no steel parts block the panoramic view offered to the passengers.

Engineering

The project’s first challenge was to find the perfect place and correct position for the car guide rails and fix them onto the shaft. After an expert team surveyed the site, it was determined that the car guide rails could not be fixed on the wall returns due to the poor concrete quality. The guide brackets implement a very special design. The car rails are in the correct place to balance the cabin weight, but the fixing points are inside the shaft recesses. This special design combines car and counterweight guide rail brackets. The same brackets are applied on both shaft sides.

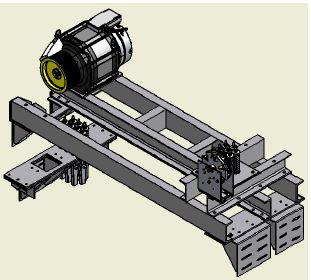

The car sling is suitable for 2:1 roping, and two pulleys are placed under the cabin. This design was chosen so that the car sling could be hidden in the panoramic cabin hoods and the steel ropes would be almost invisible, traveling around the cabin at the back side of the main guide rails. These choices result in outstanding elevator aesthetics. The car sling frame was engineered from a blank page, especially for this project, to match completely the cabin design and look like one piece. The cabin hoods provided small openings for the sling pulleys, guide shoes, sensors and lubricators, making all these fit tightly with the cabin exterior walls, to the point that they are almost invisible. Stainless steel cabin hoods fully cover all equipment. A 3D computer aided design was fully used.

Based on MASSAED’s previous decisions during the design process, an innovative steel frame for supporting the elevator machine, the rope suspension sockets and the overspeed governor had been designed to fit in a very limited space. A compact gearless machine and compact speed governor were chosen. The result was a two-level, complicated frame where everything was hidden inside the concrete shaft headroom. A special assembly and installation process was implemented, accompanied by detailed documentation to correctly guide the installation team.

Safety

The elevator was designed according to the European Elevator Directive 2014/33/EU. All safety components are fully certified according to the latest European Norm EN 81-20 and EN 81-50 to meet the highest standards of the Ministry of Culture had set.

To develop this elevator, only famous and trustworthy brands were chosen and neither exception nor compromise was made. MASSAED suppliers include:

- Metron elevator doors and locks

- Dynatech safety gear and overspeed governor

- ETN buffers

- Lafert machine

- Gustav Wolf ropes

- Metron Controller

- UCM monitoring

Technology

Exceptional ride quality combined with low energy consumption was achieved with a gearless machine from Italian brand Lafert along with the Yaskawa L1000A inverter. The Stage Micro controller main board is recognized as one of the best in floor management technology and elevator positioning. Metron variable voltage, variable frequency (VVVF) door drives are well known for their excellent operating features and optimum durability. These devices were fully programmed and parameterized by the experienced team of lift engineers to meet project specifications. In this way, accurate floor leveling, comfortable acceleration and deceleration, low level of vibrations and jerks during riding and automatic rescue operation are guaranteed.

Installation

MASSAED’s experienced installation team successfully realized the challenge of this project. The utmost modern installation methods were applied in combination with Metron guidelines. All appropriate dynamic tests had been done according to the European Norms and Directive for final inspection of the elevators. Every detail of the design and the engineering process was checked and tested to safeguard the company’s vision to design and create a masterpiece of elegance and unparalleled engineering for the U.A.E. Ministry of Culture.

Specifications

System type: Gearless, traction machine-room-less (MRL) Panoramic elevator

Capacity: 1,000 kg, 13 passengers

Speed: 1 m/s

Travel: 9,260 mm

Pit depth: 1,600 mm

Headroom: 4,140 mm

Machine: Gearless permanent magnet synchronous motor

Drive: Closed loop variable voltage, variable frequency (VVVF) control

Get more of Elevator World. Sign up for our free e-newsletter.