Peelle’s Heavy-Duty HSD System

Jan 1, 2011

The Peelle Co. displays its new Horizontal Sliding Door (HSD) system at the National Association of Elevator Contractors expo.

The Peelle Co. displayed its new Horizontal Sliding Door (HSD) system at the National Association of Elevator Contractors expo in Cincinnati on September 29-30, 2010. During the two-day show, elevator contractors, consultants and professionals stopped by the Peelle booth to inspect the door system and share comments on its applications in the elevator market.

It wasn’t uncommon to hear, “I wish I knew this were available; I just finished a job where it would have been perfect.” This is not surprising, considering the unique niche the product can fill:

- Passenger/service friendly

- A door-panel design for any width of opening that is robust in its steel thickness, welds and stiffening pans

- A source for oversized door panels; the ability to provide panels for excessively wide or high openings

- A simple design: belt driven, no cables and one operator with encoder

- A modern design streamlined to reduce parts, and make installation and maintenance easy

- Suitable for large freight elevators that can carry both passengers and their large items

- Combining what would otherwise be costly separate installations of both a freight and passenger elevator.

- A solution to cases in which the passenger elevator doors often get knocked off

- An alternative to vertical bi-parting doors

- Simple enough that multi-speed doors can be a snap to install and adjust

- A rugged door with solid sills, heavy-duty retainers and a solid support for multi-speed door tracks.

- Driven by a variable-voltage, variable-frequency (VVVF) drive system with an encoder, meaning no open or close limits to adjust

- No fascia or restrictor required

The Peelle HSD is a multi-panel, automatic door system designed to accommodate demanding applications in which robust design and reliable operation are essential. The system is provided with horizontally sliding hoistway doors, car doors with the same quantity and panel style, power operators and control equipment. The Peelle HSD advantage is in its ability to provide a full range of door size and configuration solutions for freight or service elevators that can also carry passengers (a challenge with today’s vertically bi-parting door and code). Peelle HSD doors are available up to 24 ft. wide by 13 ft., 11 in. high, as well as applications where multi-panel doors would provide savings in the hoistway width, maximizing the platform area.

Design and Features

The R&D process included a demanding in-house test that exceeded one million cycles. HSD doors and components are tested and certified in accordance with ASME A17.1 Safety Code for Elevators and Escalators and CSA B44, and fire rated to UL10 B. While the product is designed to take abuse, at the same time, it is flexible enough for freight/passenger applications. Peelle fire-tested a four-panel, side-opening (90 in. wide by 102 in. high) and six-panel, center-opening (120 in. wide by 102 in. high) configuration at Intertek and received a fire rating of 90 min. to UL10 B. The HSD also received a fire rating of 90 min. to UL10 B for two- and four-panel center-opening options, as well as two- and three-side opening options.

HSD design features are based on feedback from elevator contractors, end users and consultants. They also include:

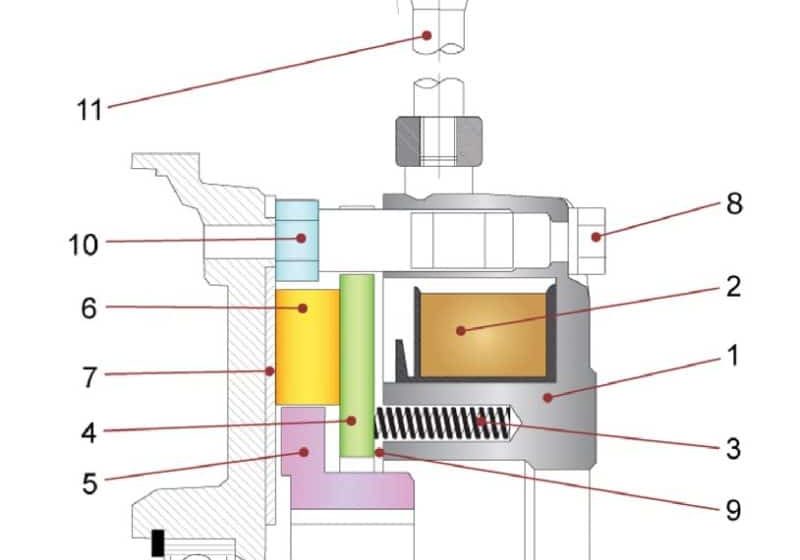

- A patented linkage system with no pulleys or cables. This linkage offers minimal adjustment and maintenance, smooth and even panel movement regardless of panel size, and quantity to accommodate a full range of HSD configurations. The linkage system has the ability to accommodate very tall panels without canting or binding.

- Reinforced panel construction with 14-gauge sheet steel reinforced with vertical stiffeners and rigid members at the top and bottom, and the ability to withstand a 1,100 lbs. of static loading on a panel 13 ft. long.

- A Track Jack mounting base that simplifies installation of the header assembly to the shaft wall; centers and levels the mounting base and uses any of the multiple slots to secure to the hoistway wall.

- A patented car door lock is a standard feature on all configurations. Tested and certified to meet North American safety requirements through CSA B44-07 and ASME A17.1-2007, it also offers a cost savings by eliminating the need for floor-to-floor fascias.

- A landing-door lock is a standard feature with all configurations, and tested and certified to meet North American safety requirements through CSA B44-07 and ASME A17.1-2007.

- Self-cleaning sills prevent door binding, canting or sticking due to build-up of debris and/or low maintenance. Damaged bars can be removed or replaced without removing the complete assembly. Capacities up to 30,800 lbs. are available in extruded aluminum, solid steel construction or stainless steel.

- Heavy-duty door-panel retainers that are built for strength and to function under extreme conditions: Peelle’s retainers capture the bottom and top tracks to ensure that the panels do not dislodge when impacted. (The top retainer surrounds the top guide, and the lower retainer sits inside the track.)

- The HSD door operator has a VVVF closed loop that is self-adjusting and has reliable operation designed for heavy-duty use (large and multiple panels). The operator is a brushless 30 VAC motor with a built-in optical encoder. The encoder provides a self-learning system that generates open and close limits electronically with limitless adjustment. Peelle includes a microprocessor inverter drive with obstacle-detection parameters and light-curtain protection, eliminating any potential material or personnel contact. The necessary power supply is 120, 208 or 240 VAC, single phase.

- Door finishes: All door panels and mechanical components are shipped with Peelle’s standard baked-on powder-coat finish. Stainless-steel cladding of up to 16-guage thickness is also available. The landing-door frames are provided with a finish to match the door panels.

Panel Configurations

- The HSD two-panel, center-opening configuration is available with Intertek Label to UL10 B for 90 min. in a maximum size of 48 in. wide by 102 in. high. Larger sizes (up to 72 in. wide by 168 in. high) are available in oversized certificate.

- The HSD four-panel, center-opening configuration is available with Intertek Label to UL10 B for 90 min. in a maximum size of 96 in. wide by 102 in. high. Larger sizes (up to 144 in. wide by 168 in. high) are available in oversized certificate.

- The HSD six-panel, center-opening configuration is available with Intertek Label to UL10 B for 90 min. in a maximum size of 120 in. wide by 102 in. high. Larger sizes (up to 216 in. wide by 168 in. high) are available in oversized certificate.

- The HSD eight-panel, center-opening configuration is available with Intertek oversized certificate in a maximum size of 288 in. wide by 168 in. high.

- HSD two-, three- and four-panel, side-opening configurations are available with fire certification in various sizes. Larger sizes are also available to suit specific project needs.

The 10-panel configuration is also available based on job requirements and an engineering review.

Job Applications

The Peelle HSD is applicable for applications in which there is no obvious or easy solution:

- Different opening heights on the same line of doors can be dealt with by a special Peelle clutch design.

- Capacities greater than 30,800 lbs. can be achieved by installing the HSD within the hoistway wall resting on a building sill in lieu of attachment to the hoistway wall.

- A combination header and sill assembly has been designed for limited floor-to-floor heights.

- An excessively wide opening with key switch control to change from normal passenger use of the four-panel center open section to a full eight-panel center open arrangement for full loading use

- Facilities with limited room for an elevator that must transport passengers and where a robust panel design is required due to the movement of freight

The Learning Curve

Peelle has always offered on-site support, supervision and/or installation. We discuss these options with all HSD customers in advance of shipment to ensure a proper installation. The Peelle HSD installation, maintenance and packing materials use color and visual tools to communicate these processes. The visual instructions list the sequence of installation, including maintenance instructions. The material list offers on-site identification of all components.

Possible Uses

Some challenging applications for which HSD is appropriate include:

- Airport terminals for passenger and luggage-cart use

- Retail stores to carry multiple shopping carts and passengers

- Museums to move its patrons and wide pieces of art

- Parking garages to transport vehicles and their operators

- Train stations to carry riders and freight

- Most applications that require heavy-duty, wide, horizontally sliding doors and the flexibility of moving both freight and passengers.

The Peelle HSD door spent several years in the R&D process and was released to the international market more than five years ago. It received its North American approval more recently and was released for the U.S. and Canadian markets. For more information, contact Mike Ryan of Peelle at [email protected] or website: www.peelledoor.com.

Get more of Elevator World. Sign up for our free e-newsletter.