Pre-Engineered Opportunities

Jun 1, 2018

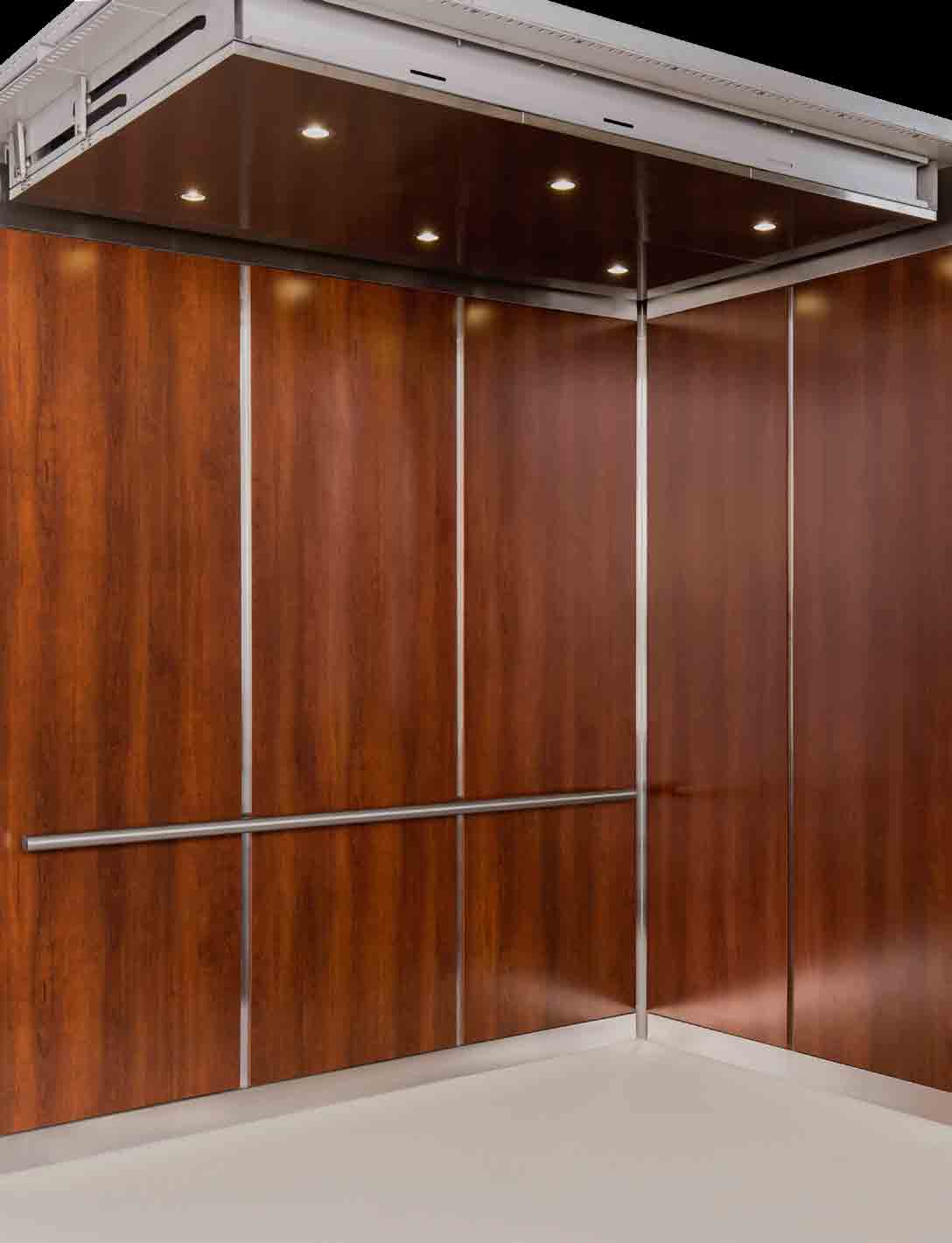

Sometimes, the perfect opportunity is right in front of us, and we look past it. Such an opportunity for elevator contractors is the potential sales and income to be gained from upgrading elevator cab interiors. Most building owners and managers regard the elevator’s visual aspect as being just as important as its functioning. It is the first impression they make on tenants and visitors once they leave the lobby. Older, outdated finishes can create an impression of poor maintenance, and reflect on the value of the tenant space.

Contractors are always looking for ways to improve elevator performance and service, as they should. Upgrading cabs’ appearance is often lower on the list of priorities, as the aesthetic considerations are competing with functional concerns for funding. Through planning, the aesthetic improvements can be included in the modernization budget, and the use of pre-engineered interiors simplifies the budgeting process. By making only a few measurements, the contractor can quickly develop budget quotes for interior upgrades.

When it comes to aesthetics, many elevator contractors will bring in outside companies to perform the work for them. This is mainly because of the complexities involving finish upgrades, scheduling and coordination. Pre-engineered cab solutions simplify the estimating, ordering and installation of new, modern finishes, giving elevator contractors control over this aspect of their projects. Concept Elevator’s Eleclip is a patented pre-engineered solution that eliminates the complexity and risks associated with cab upgrades and, thus, presents contractors with opportunities to increase revenue.

By using standard configurations, the proposal process is much easier and less time consuming. Customers need only select a panel arrangement, basic panel finishes (including laminates and metals) and ceiling types to create a budget proposal. The final finish selections can be made later.

Eleclip takes all critical design items into consideration and provides a simple solution. The estimating process only requires three measurements and basic finish selections. The ordering process is a single-page form that can be completed onsite. The installation process is simple and typically takes less than one day.

The Eleclip system is designed with a fastening clip as part of the installed reveals. By placing the reveals in predetermined locations, the installer needs to only clip on the panels and lock them into place with concealed attachments, all from inside the cab. This system also makes it easy to replace panels in the future, if needed. Short and simple installation videos and survey forms are available at eleclip.com.

Cab ceilings and lighting have always made cab renovations difficult. While many have existing lay-in ceilings with florescent light fixtures, some may have light coves or island ceilings. The Eleclip pre-engineered downlight ceiling uses a sliding tray ceiling, the frame for which two people can easily install in minutes. The metal or wood panels are then clipped to the frame, and the sliding escape panel is clipped into place. LED lighting can be used as direct or perimeter lighting.

The most common finish found in elevators is typically a code-compliant wood panel faced in plastic laminate. There are varying arrangements and laminates to use to create different designs. With Eleclip pre-engineered interiors, different materials can be used to meet the needs of the application. Metals can be cleanly applied to lightweight substrates or wood. Using V-groove technology, these panels have clean edges and sharp lines. Composite materials can also be utilized, as can stone and glass. Different combinations of panel arrangements, finishes and reveals can create a multitude of designs.

Eleclip is a simple, lightweight package that is easy to order and installs quickly. Simplifying cab renovations allows elevator contractors to expand product offerings and scope of work, which presents opportunities for more revenue.

Get more of Elevator World. Sign up for our free e-newsletter.