Preventing the Fall Hazard

Oct 1, 2019

Lessons learned as an aircraft carrier pilot and how a simple idea can be applied to the high-risk/ high-performance world of elevators

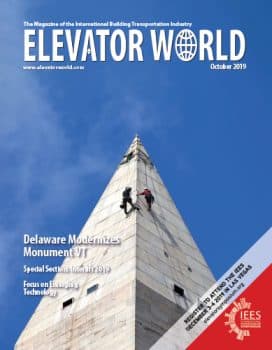

Romar Elevators and Vertical Solutions offer the Save-a-Life Barricade System intended for use in elevator hoistway construction. It quickly attaches to each side of the hoistway opening via anchors to provide a secure barricade using 2-X-4 or 2-X-6 boards. Attached pins to hold the 2-X-4s on location are included, but the anchors and boards are not. It is designed to be reused, thus reducing construction-site debris.

The idea for the product came after I witnessed high-performance, high-risk operations during 20 years in military aviation. This experience forced me to identify risk hazards: weather, sea state, terrain, fatigue, personal issues, type of equipment, night flying, military threats, enemy capabilities, etc. When I entered the elevator industry, I quickly realized our teams also work in a very high-risk environment. They encounter many of the same hazards and challenges a carrier aviator confronts. The goal is always the same: to identify hazards and mitigate them so we can complete the mission and come home safely.

The fall hazard is one of the most dangerous in our industry. It often amazes me how some hoistway entrances are either poorly secured or left completely unguarded. Ironically, it is clearly stated in the OSHA guidelines and Elevator Industry Field Employees’ Safety Handbook how to guard elevator entrances/openings. Usually, however, the most common barricade system I see is a piece of unsecured plywood leaning over the entrance, creating a false sense of security. It was obvious there must be a better way.

One day, I saw an operational guard-rail system neatly lag-bolted to the entrance walls and securely protecting the entrances at the required OSHA heights: 3, 24 and 42 in., which our co-owner and Service Manager Patrick Sheldon had made. Sheldon has been in construction for 46 years and is extremely humble, yet always seems to know the answer or the most efficient way to solve a problem. I immediately called him, asked about his barricade system and told him these were perfect for the field. After I asked why he hadn’t told anyone about it, he chuckled and said, “I told the guys who need them.” It was characteristic of him; he simply identified a need and provided a solution.

I realized the entire industry would benefit from this product. I approached Tom Palazzolo and Robin Monette of Vertical Solutions at the 2018 National Association of Elevator Contractors Exposition and told them we had a simple but “field-operational” idea. Vertical Solutions shared our passion and vision and decided to team up with us to bring it to market. We believe the final product will change the safety culture in the construction industry. It can be reused on every job, becoming part of the prestart safety checklist or job checklist.

Hazard identification is one of the most important challenges we face. Like flying around an aircraft carrier, if you make a big enough mistake in the elevator industry, you can hurt or kill yourself or another.

Get more of Elevator World. Sign up for our free e-newsletter.