Proposal to revise EN 81-20:2022, Table 6

by Dr. Gina Barney

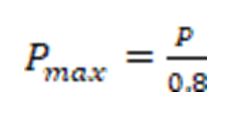

When we size a lift installation to meet passenger demand at a defined performance level, the lift traffic designer specifies the number of lifts, their rated speed, door times, etc., plus the average number of passengers (P) to be transported in each trip. The designer accommodates the statistical variation in passenger numbers by estimating the maximum number of passengers (Pmax) to be transported using:

(1)

(1)

You might then look at the in-car rating plate in the car and see 17 passengers — and believe it. But we all know, because we have noticed, that lift cars do not fill to the number of passengers indicated on the in-car rating plate.

Q1: Why?

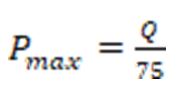

The rating plate in a lift car states the rated load (Q) and determines the maximum number of passengers (Pmax) that can be safely transported according to the formula from BS EN 81-20:2020 (BS ISO 8100-1:2019):

(2)

(2)

and the result rounded down to the nearest whole number.

Q2: Where did the 75 Come From?

It originates from the assumption a person weighed, on average, 150 lb (68 kg) and stood, on average, within an area of 2 ft2 (0.186 m2). This assumption was recommended in July 1935[A] by the U.K. Building Industries National Council, who published a Code of Practice for Electric Passenger & Goods Lifts and Escalators (COP), in which they stated:

c) A plate shall be affixed to each lift car in a conspicuous position and shall bear at least the following particulars:

(i) The contract load of (goods) lift in cwts.[B] and/or lbs.

(ii) The maximum capacity of (passenger) lift in passengers, calculated at 150 lbs. per passenger.

CEN updated and increased this estimate to 75 kg, when the new approach BSI/EN 81 to writing standards[C] was developed in 1985.[D] We don’t know why 75 kg was selected, but having worked on standards committees, they might have said, “The U.K. uses 150 pounds, so let’s do some simple arithmetic and convert the imperial measurements to metric by dividing by two.” This would add a 10% increase, as the actual divider should have been 2.205. This might offer some adjustment for human body sizes increasing over the intervening 50 years.

This Is the Answer to Question 2

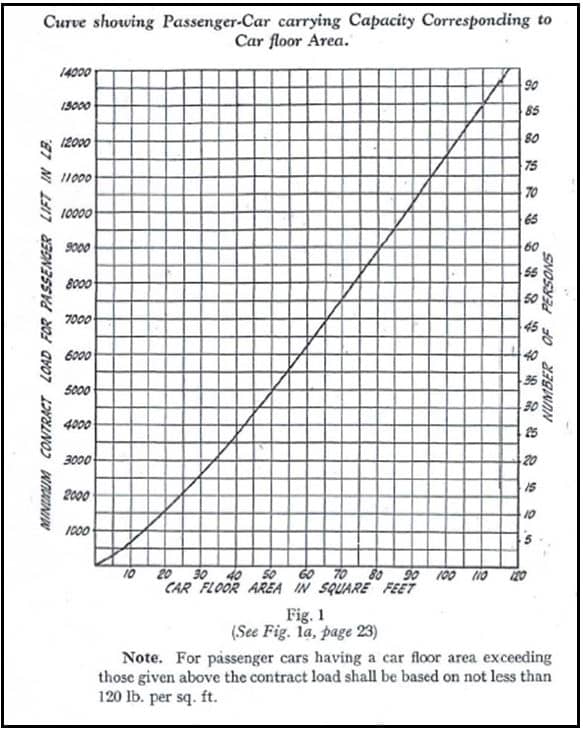

In May 1943,[E] the U.K. Building Industries National Council revised their 1935 COP to include a graph, as shown in Figure 1. This graph shows a dependent variable on its right vertical axis, number of passengers, and, on its left vertical axis, their weight in pounds (lb). The independent variable is the horizontal axis, car floor area. The assumed passenger weight continues as 150 lb per passenger. The line indicates a relationship between “Contract Load” (now called rated load) and the “Car floor area.”

The graph is nonlinear and starts with a car floor loading at 75 lb/ft2[F] and finishes at 120 lb/ft2 (see footnote to Figure 1). The Council introduced this nonlinearity in 1943, as there was a fear too many people would board the larger lifts and overload them. The passengers’ fear of crushing caused car loading to be self-regulating. Remember, accurate load weighing was not available. Versions of this graph were included in BS2655, Part 1:1958.

The 1985 standards writers took Figure 1 and selected a Renard number sequence and, with some smoothing, produced a table, Table 1.1. Table 6 in both EN 81-20:2020 and ISO 8100-1:2019 is identical to the 1985 Table 1.1 and is shown above as Table 1.

| Rated load, mass (kg) | Maximum available car area (m2) | Rated passengers | Space per passenger (m2) | Rated load, mass (kg) | Maximum available car area (m2) | Rated passengers | Space per passenger (m2) |

| 100 (a) | 0.37 | 1 | 0.37 | 900 | 2.20 | 12 | 0.18 |

| 180 (b) | 0.58 | 2 | 0.29 | 975 | 2.35 | 13 | 0.18 |

| 225 | 0.70 | 3 | 0.23 | 1000 | 2.40 | 13 | 0.18 |

| 300 | 0.90 | 4 | 0.23 | 1050 | 2.50 | 14 | 0.18 |

| 375 | 1.10 | 5 | 0.22 | 1125 | 2.65 | 15 | 0.18 |

| 400 | 1.17 | 5 | 0.23 | 1200 | 2.80 | 16 | 0.18 |

| 450 | 1.30 | 6 | 0.22 | 1250 | 2.90 | 16 | 0.18 |

| 525 | 1.45 | 7 | 0.21 | 1275 | 2.95 | 17 | 0.17 |

| 600 | 1.60 | 8 | 0.20 | 1350 | 3.10 | 18 | 0.17 |

| 630 | 1.66 | 8 | 0.21 | 1425 | 3.25 | 19 | 0.17 |

| 675 | 1.75 | 9 | 0.19 | 1500 | 3.40 | 20 | 0.17 |

| 750 | 1.90 | 10 | 0.19 | 1600 | 3.56 | 21 | 0.17 |

| 800 | 2.00 | 10 | 0.20 | 2000 | 4.20 | 26 | 0.16 |

| 825 | 2.05 | 11 | 0.19 | 2500 (c) | 5.00 | 33 | 0.15 |

a Minimum for 1 person lift. b Minimum for 2 persons lift. c 3) Beyond 2500 kg add 0.16 m2 for each extra 100 kg. |

|||||||

Table 1: {extract} Table 6 from EN 81-20:2020

I have added the rated number of passengers (rounded down), weighing 75 kg each, that can be accommodated as columns 3/7 (in grey). In columns 4/8, you will see the space each passenger is allocated (in grey).

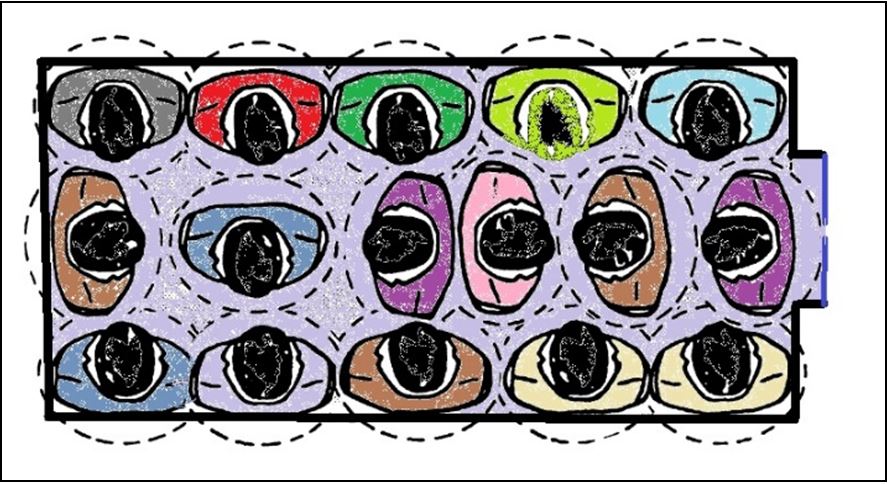

The passengers in a 450-kg car have a personal space of 0.22 m2 (1.30/6), but the passengers in a 2500-kg car have a personal space of 0.15 m2 (5.00/33). Passengers do not shrink as cars get larger. Passengers begin to intrude into others personal space (shown dashed in Figure 2). Eventually, there is no space left and intimate body-to-body contact occurs (shown solid line in Figure 2). Passengers do not tolerate this and are uncomfortable.

This is the Answer to Question 1: There is not Enough Space for Comfort.

The well-meaning legacy of the post-war years is no longer relevant, as accurate, reliable and effective load weighing is available. It is time to go linear.

What Do We Do?

Using work by Fruin and others, I suggested in Chartered Institution of Building Services Engineers (CIBSE) Guide D:1993, that the “standing area” for a person weighing 75 kg should be 0.21m2. This is now quoted extensively and accepted.

Applying this space requirement, the car area for a 33-person car would be 6.93 m2 (33×0.21).

What I am suggesting here is that the maximum area available for a specific rated load should be increased to accommodate the size of passengers, not what they weigh.

Proposal

Table 6 in EN 81-20/ISO 8100 shall be revised to reflect a linear reality.

For a range of rated loads, Table 2 shows the maximum number of passengers permitted based on 75 kg per passenger, and the maximum available car area required based on 0.21 m2 per passenger.

Rated load mass (kg) |

Maximum available car area (m2) |

Maximum number of passengers |

Rated load mass (kg) |

Maximum available car area (m2) |

Maximum number of passengers |

100 (a) |

0.37 |

1.8 |

1350 |

3.78 |

18.0 |

180 (b) |

0.58 |

2.8 |

1425 |

3.99 |

19.0 |

225 |

0.63 |

3.0 |

1500 |

4.20 |

20.0 |

300 |

0.84 |

4.0 |

1600 |

4.48 |

21.3 |

375 |

1.05 |

5.0 |

2000 |

5.60 |

26.7 |

400 |

1.12 |

5.3 |

2500 |

7.00 |

33.3 |

450 |

1.26 |

6.0 |

3000 |

8.40 |

40.0 |

525 |

1.47 |

7.0 |

3500 |

9.80 |

46.7 |

600 |

1.68 |

8.0 |

4000 |

11.20 |

53.3 |

630 |

1.76 |

8.4 |

4500 |

12.60 |

60.0 |

675 |

1.89 |

9.0 |

5000 |

14.00 |

66.7 |

750 |

2.10 |

10.0 |

5500 |

15.40 |

73.3 |

800 |

2.24 |

10.7 |

6000 |

16.80 |

80.0 |

825 |

2.31 |

11.0 |

7000 |

19.60 |

93.3 |

900 |

2.52 |

12.0 |

8000 |

22.40 |

106.7 |

975 |

2.73 |

13.0 |

9000 |

25.20 |

120.0 |

1000 |

2.80 |

13.3 |

10000 |

28.00 |

133.3 |

1050 |

2.94 |

14.0 |

15000 |

42.00 |

200.0 |

1125 |

3.15 |

15.0 |

20000 |

56.00 |

266.7 |

1275 |

3.57 |

17.0 |

30000 (c) |

84.00 |

400.0 |

a Minimum for 1 person lift (unchanged). b Minimum for 2 persons lift (unchanged). |

|||||

Table 2: Proposed revision of EN 81-20, Table 6, for traction and hydraulic lifts

The rating plate in the lift car should not show the number of passengers. The reason for this is that the average weight of a passenger varies depending on country and region of the world. See CIBSE Guide D:2020, Table A2.2 for the Body Area Index (BAI). EN 81-20:2020, Table 8, which indicates the number of passengers and the minimum car available area, is now redundant and can be deleted.

What About Hydraulic Lifts?

Table 7 in EN 81-20:2020 increases the space for each rated load, but little is gained by using it, as the example that follows Table 7 shows. The example attempts to relate two variables: rated load and available area. As a result, a 6000-kg loading on the area provided requires the sling, buffers, safety gear, etc., to be rated at 11,300 kg.

The example should ask two questions:

- “What space is required to accommodate a 6000-kg load?”

- “What rated load can be accommodated in a lift with an available car area of 19.04 m2?”

Answers, by using Table 2:

- 16.8 m2

- 6,800 kg

Q3: Is There a Safety Concern?

No. The rated load is always the primary safety variable. Taking the rated load and dividing by 75 and multiplying by 0.21 gives the necessary available car area. Alternatively, if the car area is known, the rated load is obtained by dividing the car area by 0.21 and multiplying by 75 kg.

Today, modern load weighing devices prevent any overloading, for example, if heavy goods were to be brought into a lift car.

GREEN Benefit: Lower CO2 and Embodied Carbon

As a consequence of this proposal to increase the available car area, we can either:

- Transport more people in the lift cars and can save energy for the same rated load; or,

- Transport the same number of people in lifts with a lower-rated load.

Examples

- A traffic design determines the average number of passengers to be carried as 13.6 persons. The maximum number of passengers according to (1) is 17.0 passengers. From Table 2, a lift with a rated load of 1275 kg would be selected.

- A lift with an available car area of 3.47 m2 is to be modernized. What will the new rated load be and how many passengers can be transported?

Interpolating Table 2, the lift should have a rated load of 1240 kg. It can transport 16.5 passengers on average. In practice, the lift would be rated 1275 kg.

References

[A] Building Industries National Council Advisory Committee on Building Acts and Byelaws. Code of Practice for Electric Passenger & Goods Lifts and Escalators. July 1935

[B] “cwt” is “one hundredweight” and is 112 lb.

[C] Standards were written as requirements/recommendation, not as specifications.

[D] BS 5655: Part 1:1986/EN 81: Part 1: 1985, Lifts and service lifts. Part 1 Safety rules for the construction and installation of electric lifts.

[E] Building Industries National Council Advisory Committee on Building Acts and Byelaws. Code of Practice for Electric Passenger & Goods Lifts and Escalators. May 1943

[F] The design floor loading in buildings just after World War II was 50 lb/ft2. A lift car is a small space, and so a factor of safety of 50% seems to have been used.

Get more of Elevator World. Sign up for our free e-newsletter.