While society worries that our use of cell phones and other handheld digital devices is dehumanizing and making us ever more remote from one another, this month’s issue finds that in the elevator industry, “remote” is bringing us closer to our customers and equipment. We got a HUGE (shades of Donald Trump) response to the Remote Monitoring and Maintenance focus topic for December. Both OEMs and independents wanted to brag about their mobile solutions, cloud computing, remote-monitoring and preemptive-maintenance solutions/tools. Even the 25-year-old Elevator Escalator Safety Foundation (EESF) is embracing digital technology.

On our cover is the Aurora office building in Taipei elevatored by Schindler. The article, Digital World by Kaija Wilkinson, examines how service is going from reactive to proactive via digital devices. She talked to all the major manufacturers who are partnering with either Apple or Microsoft for applications to save time and money. Independents, who are smaller and often more flexible, are also getting into the action. In A New Way of Recordkeeping, Adam Braman describes a partnership between his company, Helios, and GAL for storing records on the GALaxy IV controller in accordance with the maintenance control plan. Our historian, Dr. Lee Gray, contributes The Early History of Remote Monitoring, which was mostly a battle royale between Otis and Westinghouse in the mid 1960s to the early 1980s. Elevator faults were sent to the manufacturers by a double-track tape of recorded messages. Powered by the Cloud by Chad Apurav highlights how mobile apps are using the cloud to change data collection and give mechanics the tools they need to increase productivity. Richie Lobert of the Australian firm LML Lift Consultants looks at maintenance from the customer’s point of view in the article Effective Management of Elevator and Escalator Maintenance Contracts. Those who didn’t send in articles for our focus topic sent press releases on their latest remote-monitoring equipment. Look for these from Adams, MP Lifts and Qameleon in the Product Spotlight section.

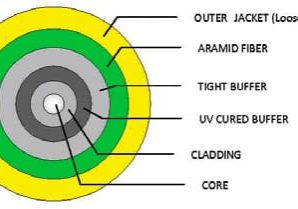

An excellent article by Richard Taylor of Draka concerned the use of fiber-optic cable and how the data is transferred within the elevator system.

Another feature of this issue is a product of the many events that come in the fall. In his coverage of the NAEC Convention and Exhibition, Lee Freeland writes about the more than 2,500 visitors and almost 200 exhibits in Boston. Excellent educational opportunities were available side by side with the exhibits, most of which are educational, too. In the midst of the National Association of Elevator Contractors’ (NAEC) event, the EESF presented its new superheroes for the Foundation’s elementary-school program and plans for future programs. (See the article EESF’s New Cast of Characters by Hanno Van der Bijl). NAEC provided a packed three days, including the honoring of one of my favorite women, Jackie Mortman. An Industry Profile on her by Wilkinson, Setting the Bar High, is also in this issue and is full of surprises, including that she is a “fearless cold caller.” Also, the VIEEW (Vertical Initiative for Elevator Escalator Women) met concurrently for a rousing presentation on safety for women, at home, at work and more.

More events in this issue include Liftronic Celebrates 30 Years in the industry. The company is one of the largest suppliers of equipment in Australia and actually has roots going back to 1921. The Fifth Symposium on Lift and Escalator Technologies by David Cooper and Dr. Richard Peters is also featured this month. A record 133 delegates attended and enjoyed a fine array of technical presentations. Last but not least, the Canadian Elevator Contractors Association (CECA) had its CECA Golf Classic.

To share some final thoughts on remote monitoring, every month we hear of our industry’s struggle with too many elevators and too few trained mechanics, leading to many maintenance routes being overloaded. Perhaps the increase of remote monitoring through small digital devices will help alleviate that situation. Equipment that is only rarely seen by a mechanic can be “seen” in his or her absence. In some cases, faults may be adjusted remotely. But, if not, it can’t hurt for a mechanic to know what’s wrong with the equipment before arriving at the building. That foreknowledge may save trips for supplies and shorten the time it takes to determine the problem. In this case, “Remote Is Good.”

Get more of Elevator World. Sign up for our free e-newsletter.