Rope Research and Products for Elevator Applications

Jul 1, 2012

Steel-wire ropes and sheaves are examined.

by Dr.-Ing. Wolfram Vogel and Lothar Sieber

Steel-wire ropes have an important interface in traction elevators. The ropes influence the dimensioning of the rope drive, as well as costs, energy efficiency, used shaft space, production, installation, diameters and maintenance. Smaller rope diameters decrease the diameters of the traction and diverter pulleys. The use of steel-wire ropes with a diameter (d) below 8 mm and a ratio of pulley diameter to rope (D/d) below 40 will allow for new possibilities in elevator construction. Steel-wire ropes covered by materials with higher friction coefficients reduce traction-pulley wrapping angle and help prevent sharp traction grooves. Flat and slim terminations for steel-wire ropes have the advantage of an increased lifetime, avoiding incline angles on the pulleys. Additionally, the method for calculation of the expected number of trips has to be improved, especially for complex rope courses in the elevator system. Certificates issued by Notified Bodies are necessary to show the suitability of new products in elevators.

Small Ropes, Small Sheaves

One of the first steps in the development of smaller rope drives in traction lifts was the decrease of rope diameter to less than 8 mm, as required by EN 81-1. With a constant D/d, the sheave diameter decreased significantly. With a D/d below 40 (e.g., in the examination certificate KP067-1),[4] a ratio of D/d = 25 and sheave diameter of D = 150 mm with the 6-mm Drako 250T is possible. An allowed D/d = 24.6 reduces the sheave diameter to D = 160 mm for the 6.5-mm rope in the same construction.

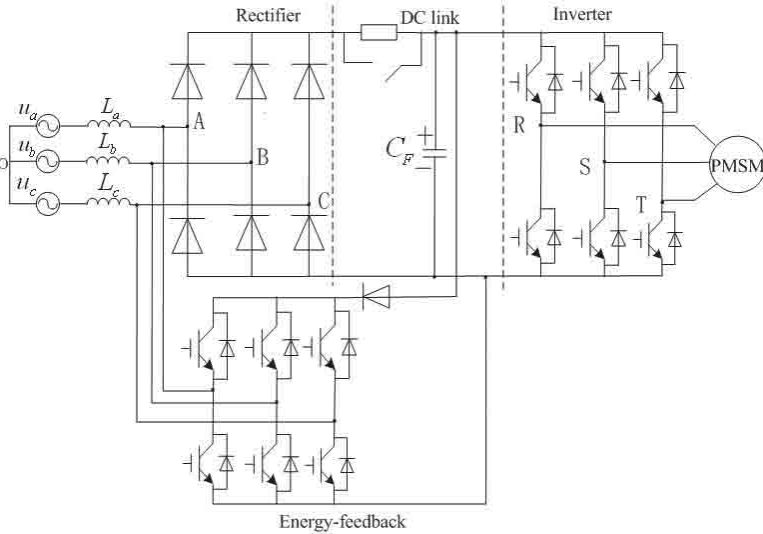

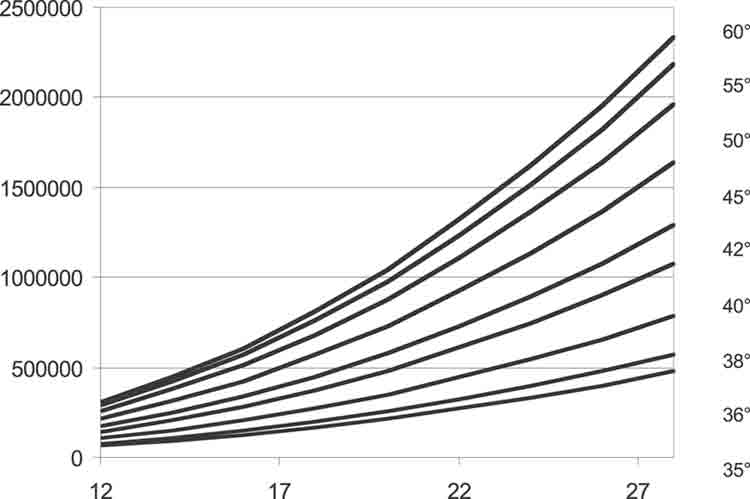

The KP067-1 certificate[4] is based on lifetime bending tests, statistics and an approved lifetime calculation[1] covered by the traditional calculation of traction capacity for V-grooves and semicircular grooves with undercut. The results are decision graphs (Figure 1) for the calculated and expected number of trips. The bending sequence is one bending over the traction pulley and two bendings over the deflection pulleys. After the traction capacity calculation, a lift manufacturer would need to decide on the parameters D/d of the traction and deflection pulleys, and the safety factor. The calculated number of trips by the KP067-1,[4] mirrored with the expected travel frequency, will lead to the rope life length. The decision graphs are valid for steel and plastic deflection pulleys in traction and hydraulic lifts.

Lifetime Calculation

Influenced by Reverse Bendings

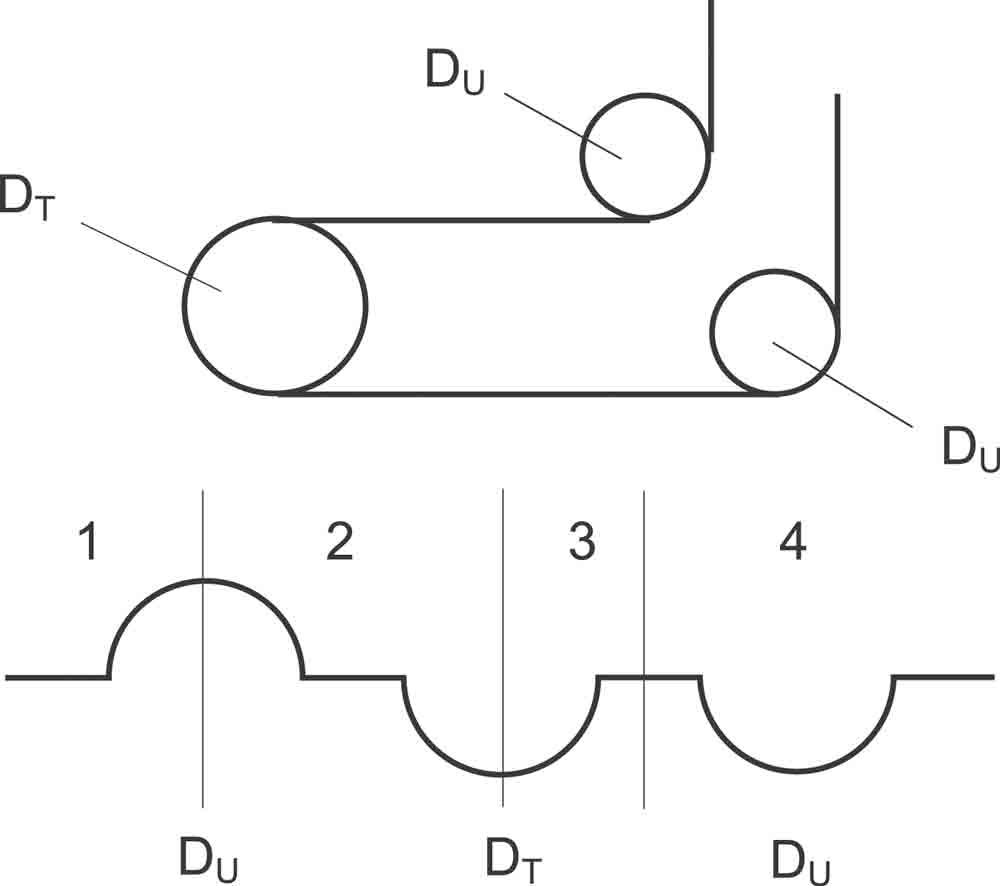

Rope lifetime calculations used for the Drako KP067-1 certificate [4] respected only bendings in the same direction. When reverse bendings (Figure 2) are used, their influence on rope lifetime is often underestimated. A calculation of the service life must take into account the bending sequence in the rope section, which is subjected to the greatest level of stress. Once the bending sequence and elements are known, it is possible to attribute the influences of reverse bending and the shaped groove. A number of bending cycles must be calculated for each bending element and collated to the number of trips using the damage accumulation hypothesis put forward by the Palmgren-Miner Rule. Attention must be paid when using this bending element model not to under or over represent the influence of either reverse bending or shaped groove, both of which exert an extreme impact on rope life. Further certification will also cover this type of bending.

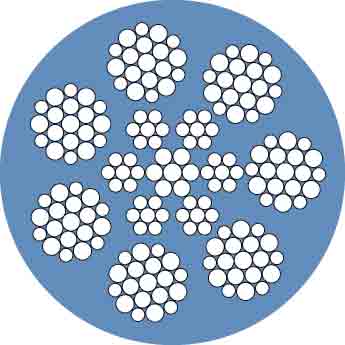

Plastic-Covered Rope

KP067-1[4] covers the steel wire rope D250T in 6 mm, 6.5 mm and 8 mm for D/d ≥ 24.6 and, in principal, open safety factors. But, the product’s influence on rope lifetime will be affected. Use the figures provided here to get an idea of what to expect. KP067-1[4] covers steel-wire ropes with limited steel/steel friction coefficients. To increase the friction, using a plastic cover is helpful. The advantages of this include a long lifetime caused by reduced pressure, round grooves, silent run and reduced wrapping angle. The PTX300 plastic-covered rope is certificated in KP195[5] with detailed instructions and discard criteria.

Rope Termination: T-Socket

The T-socket shown in Figure 4 illustrates a patented termination, which allows an installation of the ropes. This is especially important for small ropes without incline angles,[3] as the lifetime is not disturbed by additional stresses and rope movements. Additional measures such as screws and springs help equalize rope forces.

Conclusion

The steel wire rope is an interesting construction element of traction lifts and covers installation, maintenance, safety requirements, traction capacity and comfort aspects. It is important and requires a thorough understanding of what occurs after varying even only one parameter. Certificates based on scientific research will help to use the ropes, even in heavy-duty treatment, in a safe way.

Figure 2: Reverse bending[2]

Figure 3: Plastic-covered steel rope (PTX300)

Figure 4: T-socket[3]

References

[1] Feyrer, K. (2002). Drahtseile. Springer Verlag Berlin.

[2] Vogel, W. “The Impact of Reverse Bendings in the Rope Drives of Traction Lifts.” Lift Report 36(2010) 2, p. 14-16.

[3] Vogel, W. & Scheunemann, W. “Safety and Reliability of Rope Terminations in Traction Lifts Geplant.” Lift Report 37 (2011) 6.

[4] “Certificate Concerning the Examination of Conformity KP067-1 – Rope Drive for Use as Part of the Machine for Traction Drive Lifts Resp. Indirect Acting Hydraulic Lifts with and Without Reduced Number of Travels.” Pfeifer Drako/TÜV SÜD 2011.

[5] “Certificate Concerning the Examination of Conformity KP195 – Rope Drives with a Rope with Plastic Coat-ing for Use as Part of the Drive for Traction Lifts Type Drako PTX300.” TÜV SÜD 2012.

Get more of Elevator World. Sign up for our free e-newsletter.