Your author believes they are infeasible at this point.

Key words: ChatGPT, MMLS (Multi-Mobile Lift System), Ropeless Lift, Counterweight-less Lift, Maglev, Linear Motor

1. Introduction

In order to test ChatGPT, I asked it a question on April 4, 2023: Is a ropeless/counterweight-less elevator possible or not? The answer was:

“Yes, ropeless or counterweight-less elevators are possible, and they are already being developed and tested by companies such as ThyssenKrupp AG, Hitachi and others. These elevators use magnetic levitation [maglev] technology, similar to that used in high-speed trains, to lift and lower the elevator car. The elevator car is propelled by linear motors installed in the shaft walls, and the car moves horizontally to reach the desired floor. These elevators offer numerous advantages such as faster travel times, reduced energy consumption, and the ability to have multiple elevator cars moving in the same shaft at the same time. However, they are not yet widespread and will require significant infrastructure changes to existing buildings to install.”

1.1 Introducing TRIZ

TRIZ (from the Russian теория решения изобретательских задач) was developed by Soviet inventor and science-fiction author Genrich Altshuller (1926-1998) and his colleagues in 1946. In English, the name is typically rendered as “the theory of inventive problem solving,” and occasionally goes by the English acronym TIPS.

The basic principle of TRIZ is that a technical problem is defined by its contradictions. That is, if there are no contradictions, there are no problems.[1]

1.2 Introducing Quality Function Deployment

Quality function deployment (QFD) is a method developed in Japan beginning in 1966 to help transform the voice of the customer into engineering characteristics for a product. Yoji Akao, the original developer, described QFD as a “method to transform qualitative user demands into quantitative parameters, to deploy the functions forming quality, and to deploy methods for achieving the design quality into subsystems and component parts, and ultimately to specific elements of the manufacturing process.”[2]

As function or quality will spend engineering resources, the designer should consider which functions are essential and which functions are negligible. The quality should be determined by reliability; it should be good enough to maintain a high reliability over a certain period.

For an example regarding quality: The shutter of a Japanese film camera had a 40K lifecycle, while the shutter of a German film camera had a 100K lifecycle. A roll of 35-mm film can be made into 40 shootings, so a 40K lifecycle would cost 1,000 rolls of film; if an ordinary photographer took 100 rolls a year, the shutter of the camera would be able to last 10 years. So a 40K lifecycle is a reasonable specification, while 100K would be too long for ordinary photographers.

Another example regarding function: I bought a 28-in. color TV in 1997; the function Picture in Picture (PIP) was popular then. The 28-in. color TV with PIP had a price equal to one 28-in. color TV without PIP plus one 9-in. color TV. Actually, the PIP function is almost useless, but it was very expensive at that time. This meant, “The 9-in. icing on a 28-in. cake is more expensive than a 9-in. cake.” These kinds of costly functions should never be taken into account when we design and develop the products.

2. Background

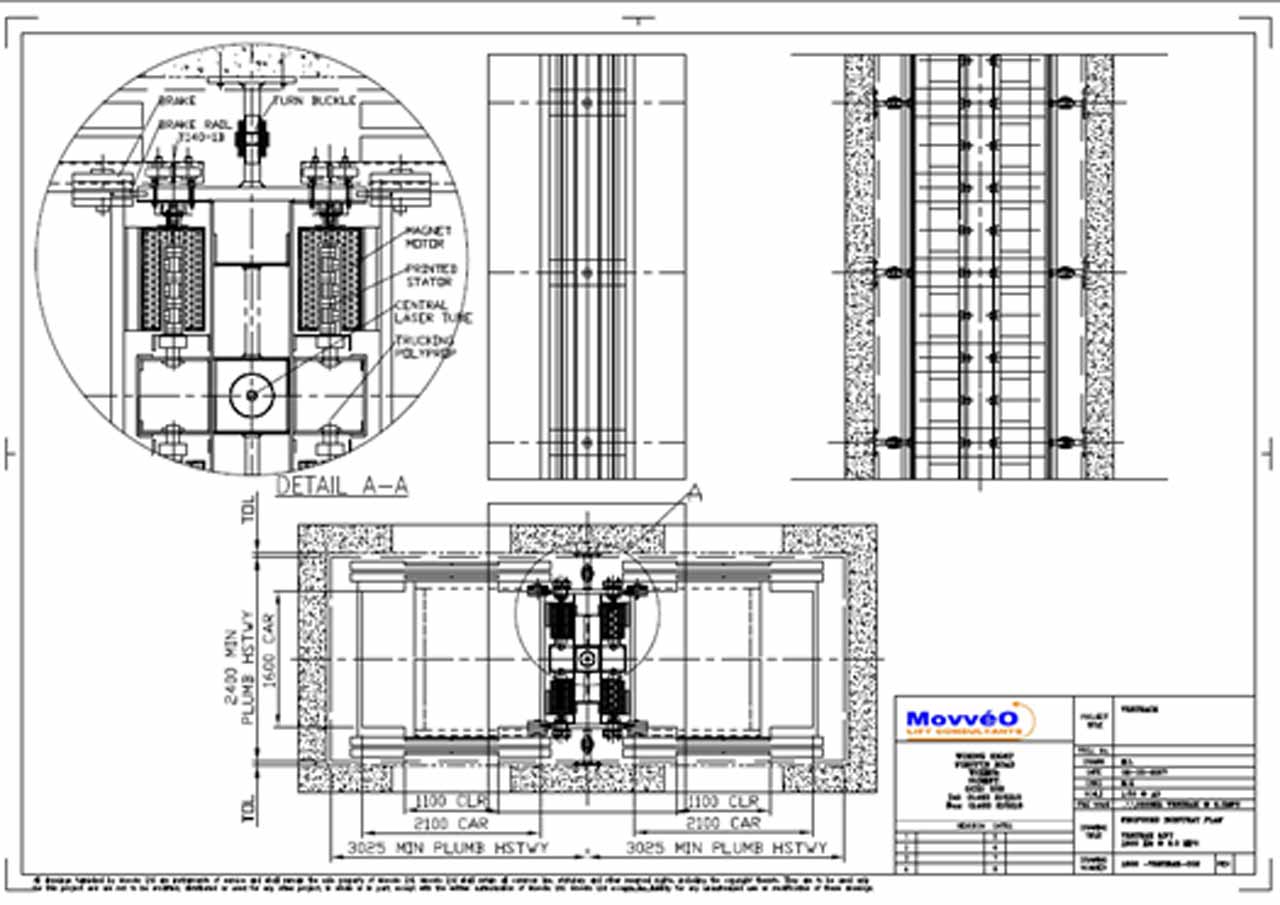

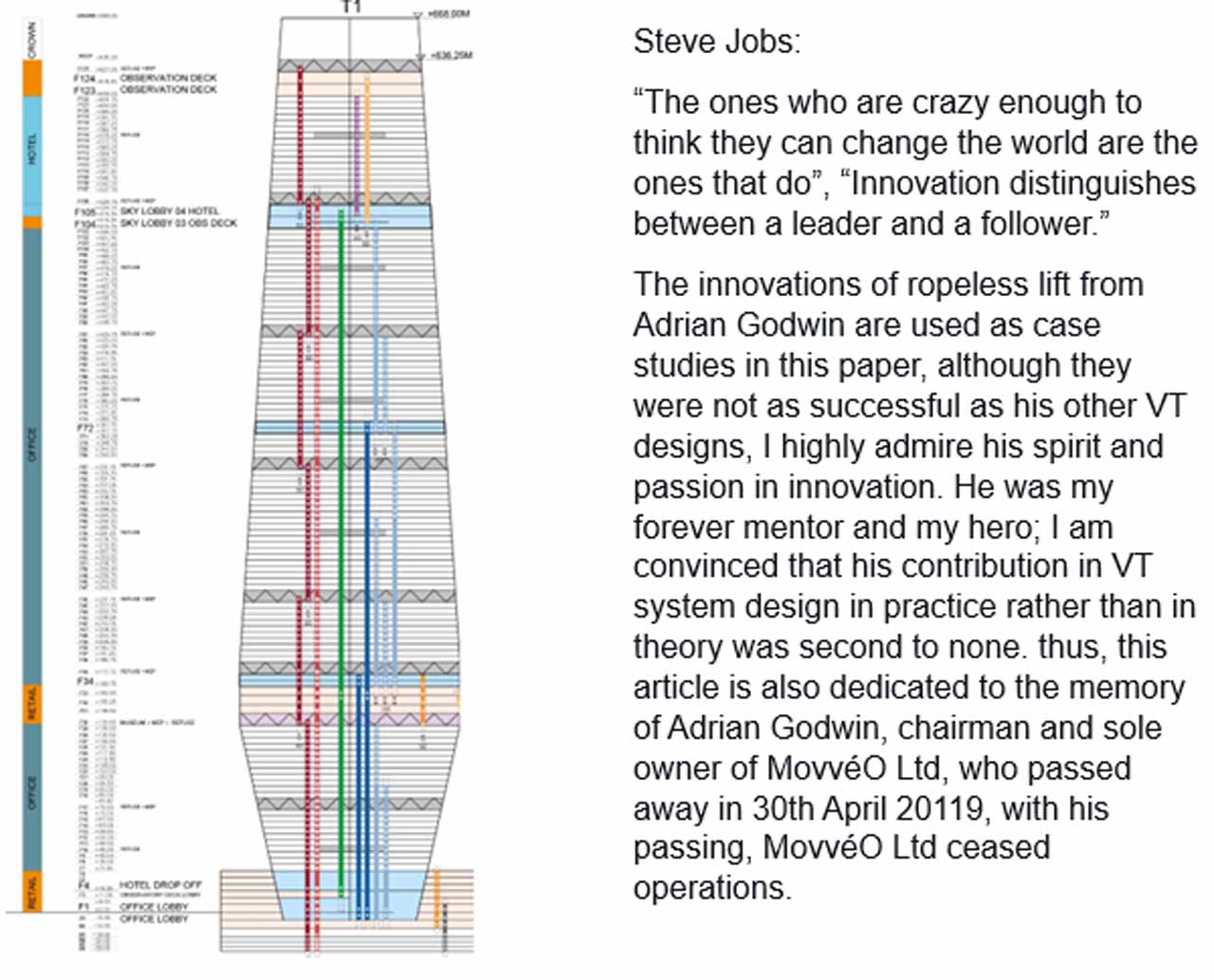

I joined MovvéO Ltd. in June 2014 — the company was called Lerch Bates Europe at that time — and I was the design manager until May 2019. During that time, I was responsible for all detailed vertical-transportation (VT) designs by MovvéO.

My former boss Adrian Godwin had an electrical background. His conceptual VT designs had always been brilliant: His designs for lift control systems — traffic analysis application Adsimulo and mobile phone app AdInspect are still at the leading edge in the VT consultancy industry. Godwin created many innovative ideas in VT system design. His mechanical designs included “Skytrak” (multiple cars in one curved hoistway), a concept that won the IAEE (International Association of Elevator Engineers) inaugural prize for “High-Tech” Innovation in 2010. This and other ideas, especially the ropeless “Vertrak” with multiple cars in one vertical hoistway (similar to ThyssenKrupp Elevator’s MULTI but with a different mechanism) were very difficult (or impossible) to realize, as he underestimated the technical complexity and overestimated the market demand.

Godwin was not able to use computer-aided design, while I am a professional mechanical engineer with an MSc degree in engineering design and engineering design management; I am also a good electrical engineer: The result of self-learning in China. It is possible for a mechanical engineer to gain electrical knowledge at home or at work, as such knowledge is based on logical thinking in mathematics and physics, as well as the understanding of advanced theories, but not vice-versa, as mechanical design skills and knowledge would be mainly based on special training in the college/university setting and practical experiences. I don’t believe self-learning from home could train a good mechanical engineer or designer.

There are some differences between Godwin and me, as I believe the key to engineering design is to well-deploy the function and qualities following QFD, so I always use well-established technology to modify existing standard products, instead of creating a new product. I also focus on mid-range products rather than top-range, because the mid-range products are always in the greatest demand and have the biggest margin in the market. As consultants, we should use our experience and well-known/well-established technology to help our clients achieve success.

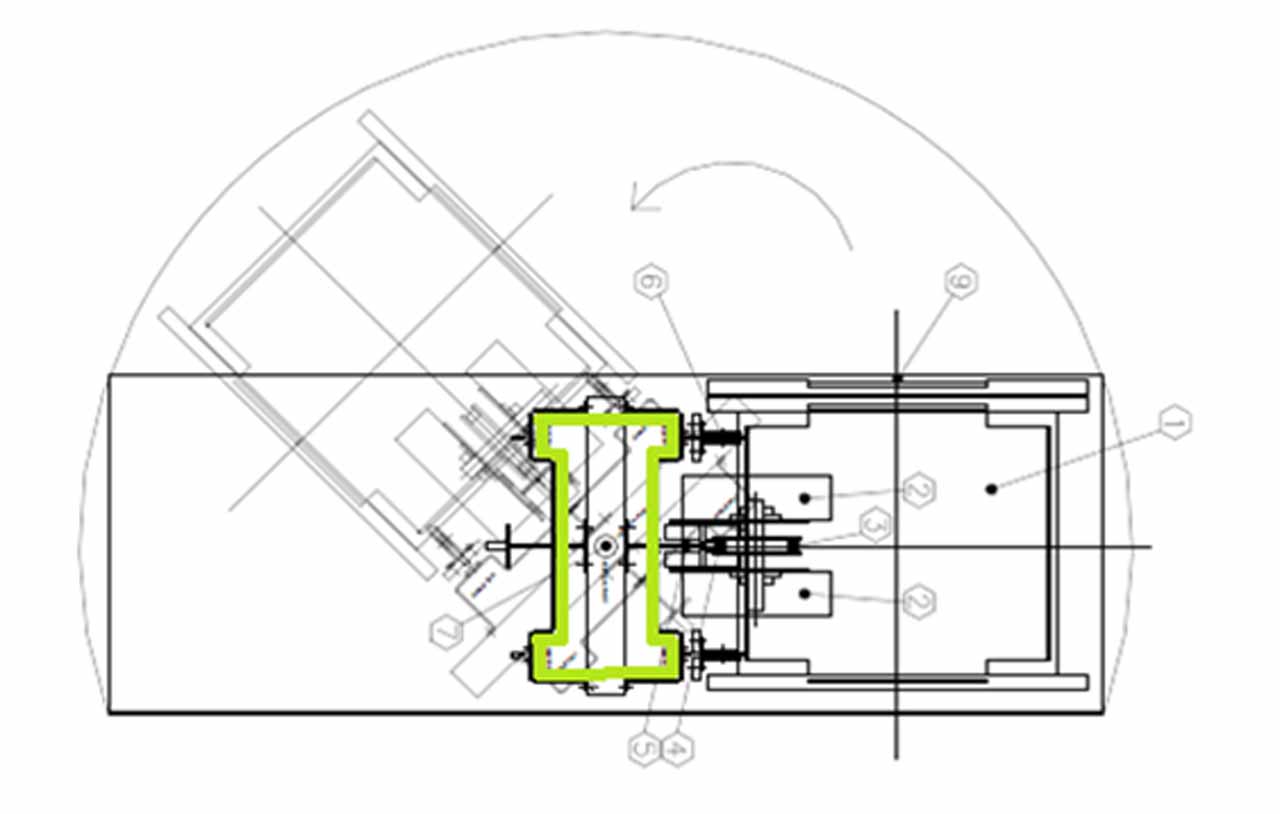

Although I have never done any research or design in ropeless lifts, Adrian and his father, Michael Godwin, often requested (not required) me to create drawings for their research of ropeless lifts. I always agreed to the request and did the drawings without saying anything or showing any reluctance. To be honest, I hate those designs so much: Firstly, I didn’t think the mechanism would work; and secondly, they had never taken any advice from me.

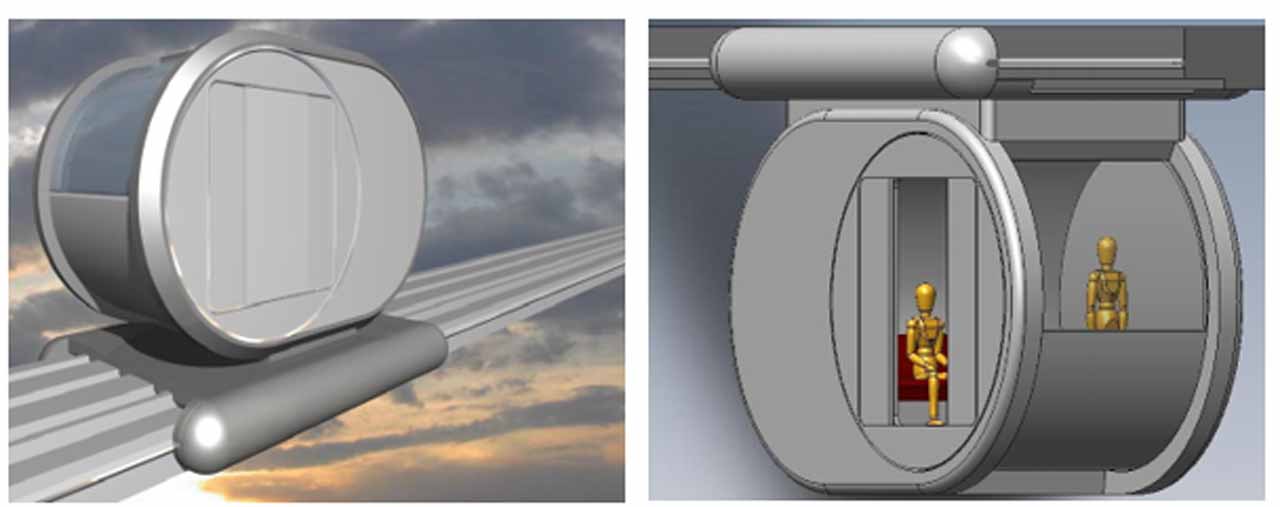

But Adrian had to rely on me to create the drawings. I just followed his instruction to work as draftsman without saying anything. He had always been very satisfied with my drawings. I even made a 3D animation demo of the Vertrack ropeless lift for him (Figure 4).

3. Adrian Godwin’s Ropeless Lift Design

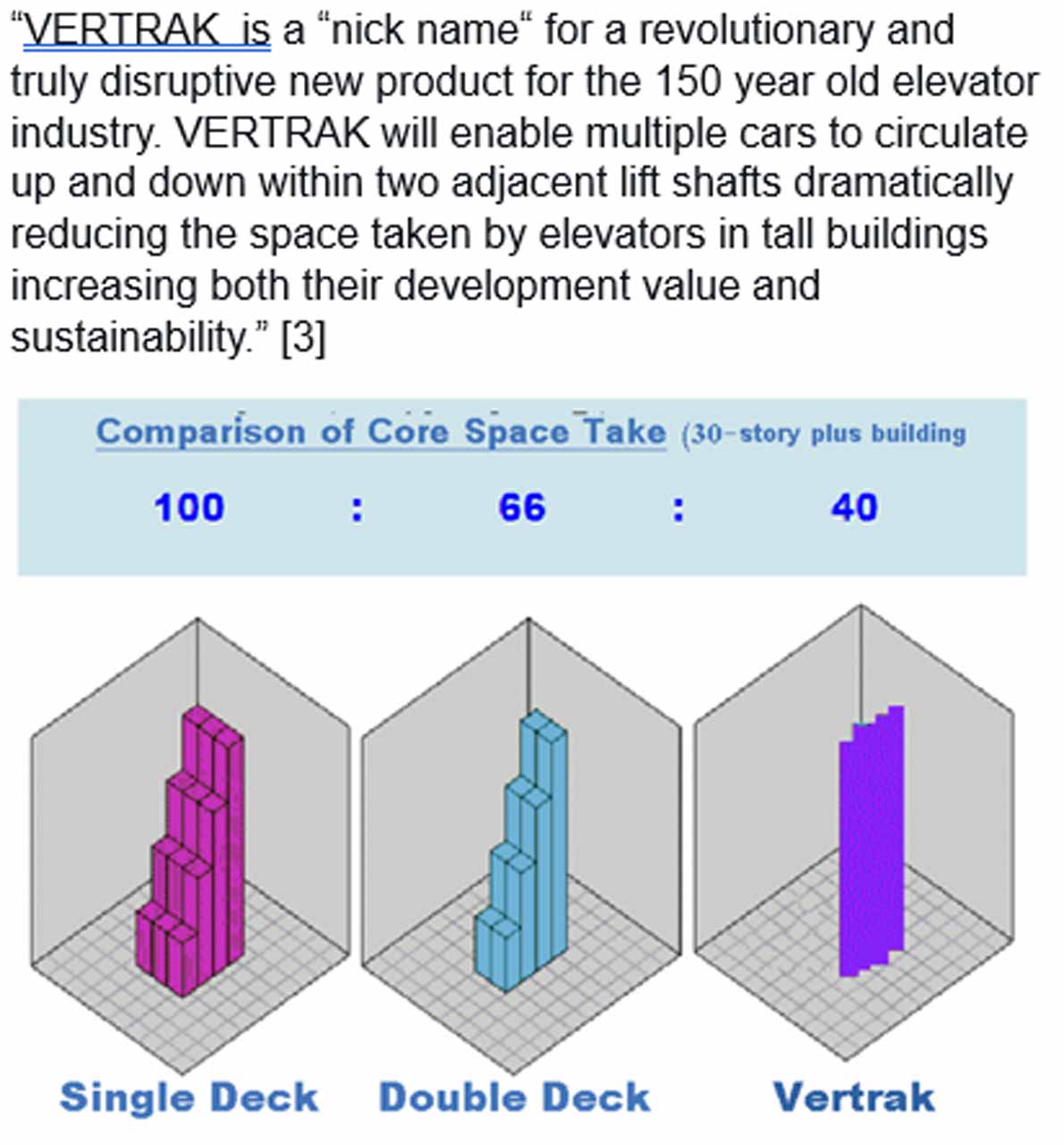

3.1 Value Generation

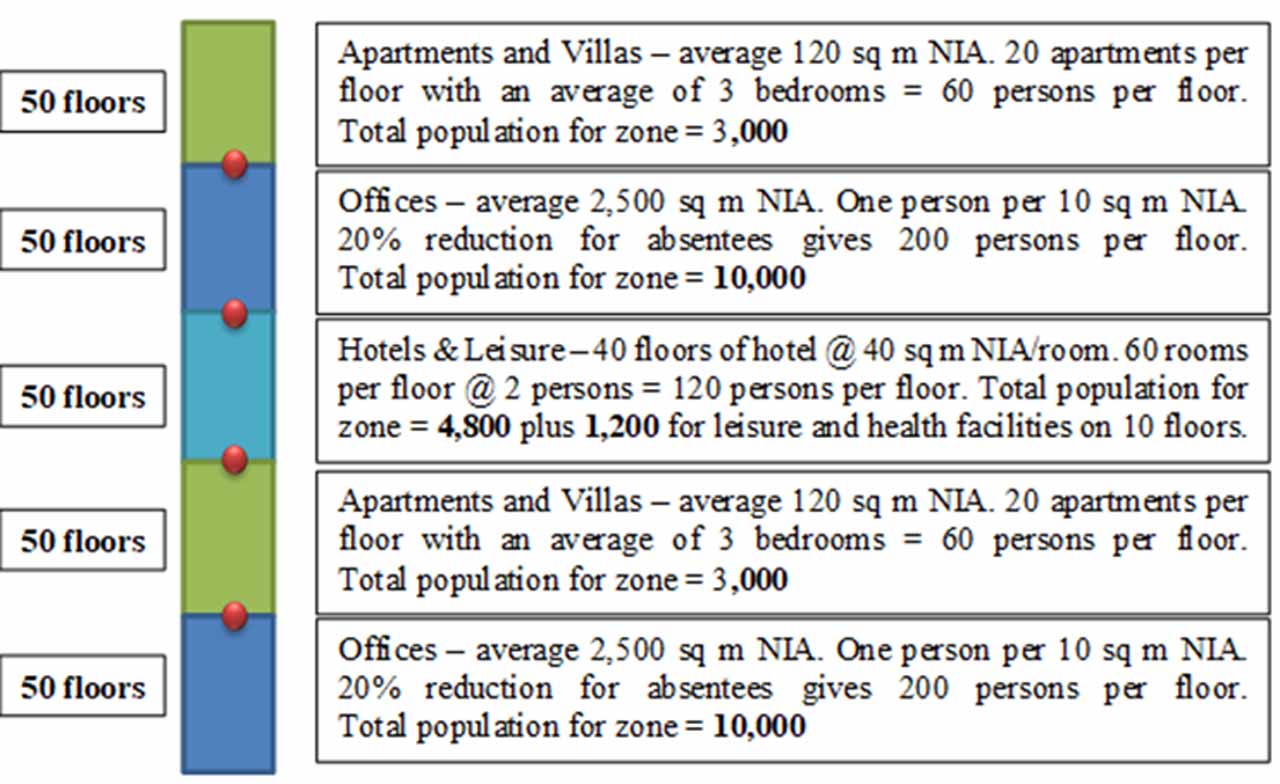

3.2 Advantages of Multi Mobile Lift System (MMLS)[4]

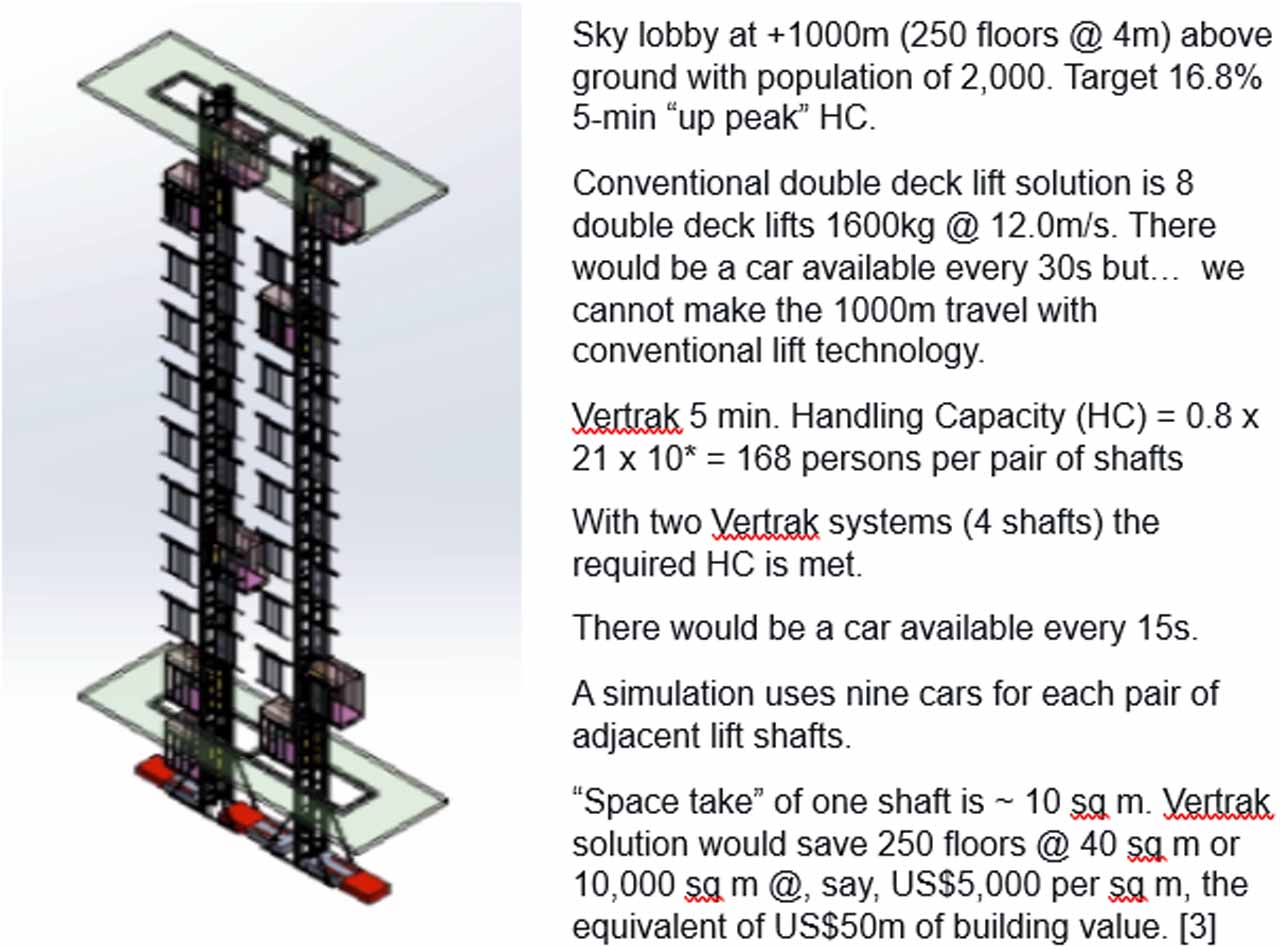

- MMLS provides 80% increase in 5-min HC to a destination 600 m above ground.

- Just one MMLS can give us an adequate “quality” of service of around 25 s.

- MMLS can give us the same handling capacity for destinations 60, 600 or 1,200 m above ground.

- MMLS has no requirement for high speed and, in fact, speed will only influence journey time.

- For hotels and/or residential facilities, the conventional solution loses handling capacity.

- MMLS has equally high handling capacity in both directions with no degradation in 5-min HC.

- MMLS also offers the prospect of being able to interconnect between multiple sky lobbies.

3.3 Adrian Godwin’s Conclusions[3]

- MMLS makes a 1,000-m tall building viable.

- MMLS offers building efficiencies of 75%-plus.

- MMLS enables sustainable megatall buildings.

- Traffic simulation capabilities for MMLS are required.

- Strategies for fire, goods and waste are required.

Godwin assumed the maximum speed of his ropeless lift is 4.0 m/s and the building height is minimum 1,000 m. So, the waiting time can meet the criteria. Adrian intentionally or unintentionally ignored the travel time to the destinations, even if the speed of the car could be 4 m/s and the travel time from the bottom floor to the top floor of the 1,000-m building would be longer than 250 s (4 min and 10 s).

When the speed is 2.5 m/s, the travel time from the bottom floor to the top floor of the 1,000-m building would be longer than 400 s (6 min and 40 s).

The situation is similar to a customer inquiry in the past: “The conventional control has shorter waiting time than destination control. Why did you recommend destination control to us?” My answer was:

“Because the conventional control moves the queue from the lift main lobby into the lift cars so the waiting time will be shorter, but the travel time to destination will become unbearably long as the car may stop at every floor. Destination control needs longer time to group the passengers, so as to minimize the number of stops, as a result, the waiting time would be longer, but the travel time will be much shorter.”

ChatGPT’s answer:

“The MULTI system was designed to operate without ropes, using linear motors and magnetic levitation technology to move elevator cars vertically and horizontally. This innovative design allowed for multiple elevator cars to operate in a single shaft, increasing the capacity and efficiency of the system. According to Thyssenkrupp, the MULTI system had a maximum capacity of 1000 kg (or approximately 13 people) per elevator car, and a maximum speed of 5 m/s. However, it’s worth noting that the actual capacity and speed of the system could vary depending on factors such as the number of elevator cars in operation and the specific installation environment.”

I think a 1000-kg capacity is possible, because the MULTI system has a wider car than Vertrack’s deep car, but a maximum speed of 5 m/s would be impossible.

4. Five Principles To Evaluate Invention or Design

Your author believes experienced people know what cannot be done rather than what can be done. Meanwhile, technical measures are always the last resort to solve a technical problem. Before that, QFD should be taken into account. Therefore, following the principles of TRIZ and QFD, the author has summarized five principles to evaluate design or invention:

4.1. The Design/Invention Must Not Have Unsolved Fundamental Contradictions Left.

E.g., low speed versus high-rise in the invention of ropeless lift. Linear motor self-weight versus high-rise 1,000-m-plus.

For the speed of the office lifts, a rule of thumb is that speed=travel m/20 s so that the passenger lifts should be able to travel from the bottom floor to the top floor with a few intermediate stops within 60 s.

For any lift, the minimum travel time from the bottom floor to the top floor should be within 60 s. If so, for the passenger lifts in a 1,000-m building (residential tower or hotel at the top stack), the speed shall be at least 1,000 m/60 s = 16.67 m/s.

4.2. The Design/Invention Must Not Disobey Any TRIZ Principles of Invention.

Following Altshuller’s insight, the theory of TRIZ developed on a foundation of extensive research covering hundreds of thousands of inventions across many different fields to produce a theory that defines generalizable patterns in the nature of inventive solutions and the distinguishing characteristics of the problems that these inventions have overcome.[1]

If any design is not following the TRIZ principle, it is very likely infeasible.

E.g., a high-rise elevator has no counterweight, but using a counterweight is one of the 40 TRIZ principles for hoisting equipment (Table 2).

| 1. Segmentation | 2. Extraction | 3. Local Quality | 4. Asymmetry |

| 5. Consolidation | 6. Universality | 7. Nesting | 8. Counterweight |

| 9. Prior Counteraction | 10. Prior Action | 11. Cushion in Advance | 12. Equipotentiality |

| 13. Do It in Reverse | 14. Spheroidicity | 15. Dynamicity | 16. Partial or Excessive Action |

| 17. Transition into a New Dimension | 18. Mechanical Vibration | 19. Periodic Action | 20. Continuity of Useful Action |

| 21. Rushing Through | 22. Convert Harm into Benefit | 23. Feedback | 24. Mediator |

| 25. Self-Service | 26. Copying | 27. Dispose | 28. Replacement of Mechanical System |

| 29. Pneumatic or Hydraulic Constructions | 30. Flexible Membranes or Thin Films | 31. Porous Material | 32. Changing the Color |

| 33. Homogeneity | 34. Rejecting and Regenerating Parts | 35. Transformation of Properties | 36. Phase Transition |

| 37. Thermal Expansion | 38. Accelerated Oxidation | 39. Inert Environment | 40. Composite Materials |

Table 2: The 40 TRIZ principles of invention

A counterweight has the following functions:

- Compensates for the weight of an object by combining it with another object that provides a lifting force.

- Compensates for the weight of an object with aerodynamic or hydrodynamic forces influenced by the outside environment.

ChatGPT:

“The maximum acceleration of the Shanghai maglev train is about 1.5 m/s² (4.9 ft/s²) and it can reach a top speed of 430 km/h (267 mph) in 4 min.”

A=F/M, for ropeless lift a=[F-g*(P+Q)]/M, as M=P+Q, so without CTW, F=a*(P+Q)+g*(P+Q)=(g+a)*(P+Q)=(9.8+1)*(P+Q),

Where F=driving force, A=acceleration, P=passenger weight in kg, Q=car weight in kg, g=gravitation acceleration.

Acceleration should be at least 1 m/s2 for a high-rise lift, so the driving force per kilograms mass of a ropeless lift will be 10.8/1.5=7.2 times that of a maglev train. This is why, for lifting equipment, a counterweight will be needed. For a maglev train, this is F=a*(P+Q)+ Fr (Fr=resistance force). From here, it can be seen, a maglev train is able to work horizontally, but it is not so easy for it to work vertically.

In addition to the above mentioned, the maglev train will only have two stations and one stop per journey (the Shanghai Airport maglev train) or a few stops (the maglev train project between Tokyo and Osaka in Japan has nine stations and eight stops per journey), while the lifts in a 1,000-m building will serve 250 floors, which means 249 potential stops. Frequent acceleration and deceleration will cause other, even bigger, issues. As a result, the idea of the maglev train will not work with a ropeless lift. So, using the concept of a maglev train to build a ropeless lift is inappropriate.

4.3. “The Icing Shall Never Be More Expensive Than the Cake.”

E.g., a ropeless lift will be more expensive than the low-rise building where the lift may be installed. A maglev train is a part of the infrastructure of a city or a country, so it may be possible for a mega city or a country to build a maglev train, but for a low-rise building to install a ropeless lift is unrealistic.

ChatGPT:

“The cost of building a maglev train system varies depending on various factors such as the distance to be covered, terrain, design, materials used and other factors. The construction of the first commercial maglev train in China, the Shanghai maglev train, cost approximately US$1.2 billion for 30 km (US$40,000 per meter one way). The proposed maglev train project between Tokyo and Osaka in Japan is expected to cost around US$100 billion for 285.6 km. The cost of building a maglev train system is usually higher than that of a traditional high-speed rail due to the technology involved. However, the increased speed and efficiency of maglev trains may result in a significant reduction of operating costs over time. But the maglev train is for public transportation as the infrastructure in a city or in a country. The investment would be able to be paid back in the future.”

4.4. A Single Breakdown in a Subsystem Shall Never Cause a Systematic Failure.

E.g., one of the ropeless lift’s multi cars breaks down in a one-way single shaft. An additional issue relevant to rescue must be taken into account, which is inaccessible to the lift car when the lift is broken down in the sky.

4.5. Never Challenging the Limitation; Any Mechanical Product Has a Physical Limitation.

When a device is approaching the limitation, the outcome is not proportionate to the input. If so, the concept will need to be changed. For example, if 1,000-m is the limitation of the building height, I would rather accept 800 m as the maximum, as the cost of two 800-m buildings with double the usable area may be less than a single 1,000-m building.

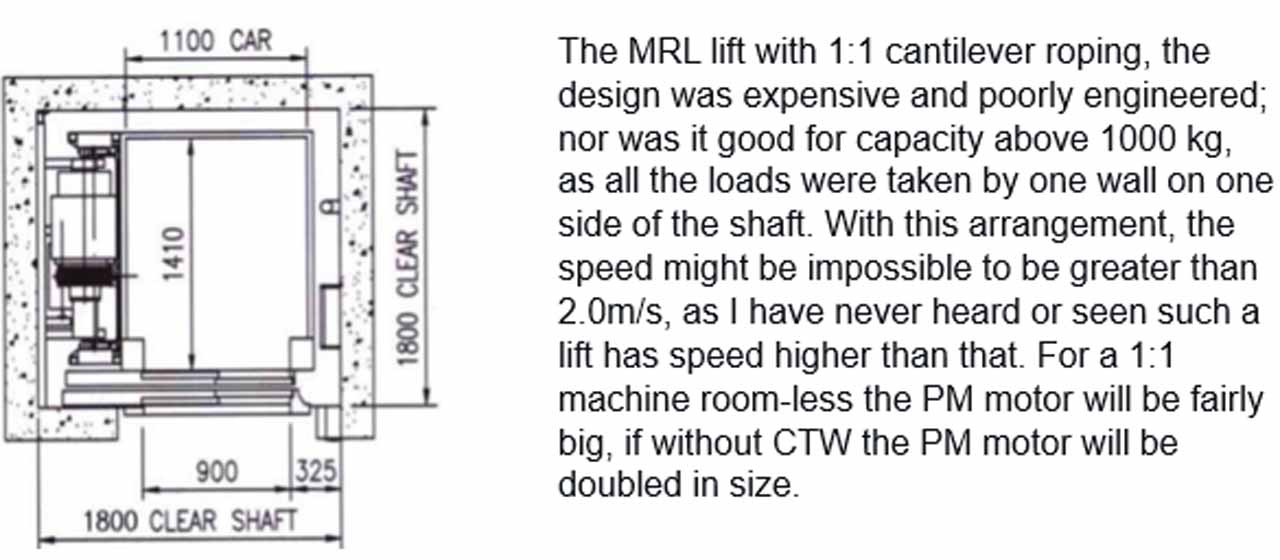

The ropeless lift car will be similar, with a 1:1 (roping) cantilever machine-room-less (MRL) lift car without counterweight.

ChatGPT:

“In general, the maximum speed of a 1000 kg cantilever-style elevator is typically around 2.5 to 3 m/s. However, this can vary depending on several factors, including the height of the elevator shaft, the capacity of the motor and the safety features incorporated into the elevator system. It is always important to follow the manufacturer’s guidelines and local safety regulations when operating an elevator to ensure safe and reliable performance.”

Thyssenkrupp Aufzugswerke Gmbh, which no longer exists, used to have a slogan: “We accept no limit.”

But Steve Jobs said:

“My model for business is The Beatles. They were four guys who kept each other’s kind of negative tendencies in check. They balanced each other, and the total was greater than the sum of the parts. That’s how I see business: Great things in business are never done by one person. They’re done by a team of people.”

Similarly, my model for product development is Japanese QFD: Any part or component has average or above-average quality, but they balance each other, and the total performance is greater than the sum of the parts or the components.

5. Possibility of Ropeless lifts

As mentioned early, never challenge the limitation. When it is approaching the limitation, a new concept needs to be invented.

5.1 PM Motor Characteristics

T=BLR2πRA=2BA(πR²L)=2BAV

where T=torque (total), B=magnetic field strength, L=conductor length in the magnetic field, R=equivalent radius of the motor, and V=motor volume (motor equivalent section of X length).

Due to magnetic saturation, magnetic field strength cannot be increased infinitely. To increase torque, only two ways are available: increasing the motor’s diameter and/or increasing the motor’s length. That is why PM motors are usually made flat (skinny but with large diameter) to obtain the highest possible torque. Another purpose of a large-diameter rotator is to obtain a larger ratio between the rotator and driving sheave, as the torque is proportional to the square of the radius.[5]

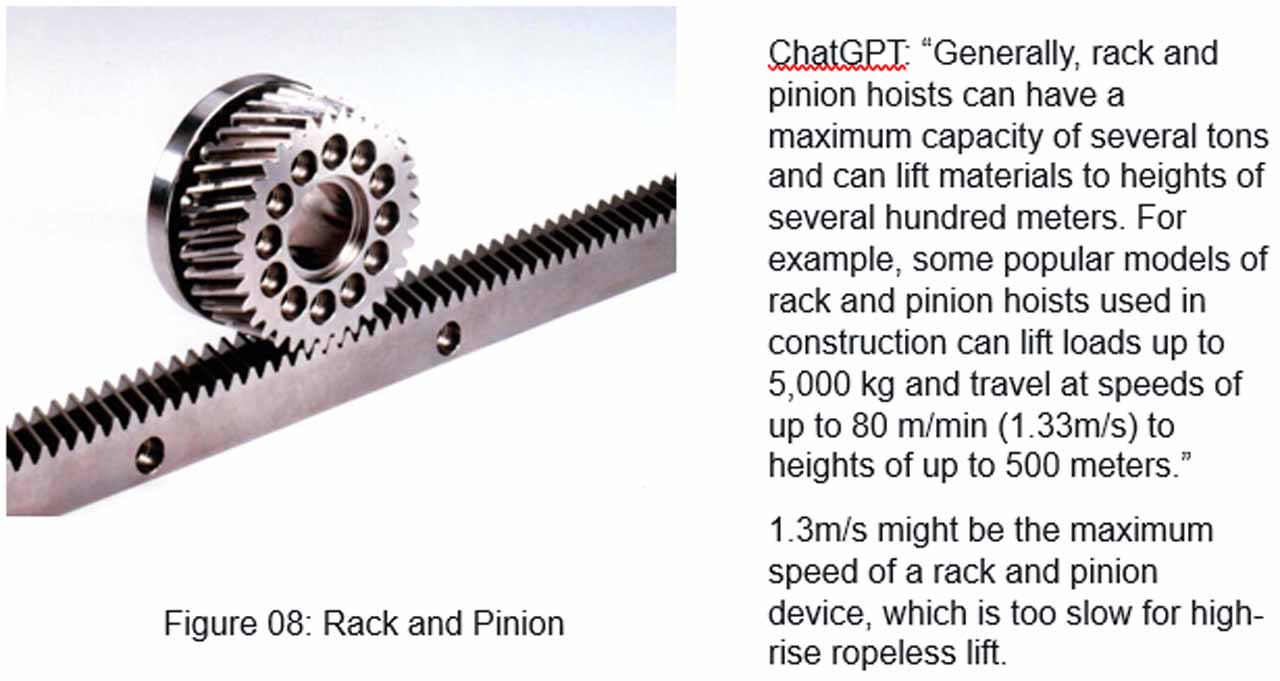

I believe the ropeless lift will have to have the PM motor in the car rather than driven by linear motors. As a result, the ropeless lift may only be in two styles:

5.2. Rack and Pinion

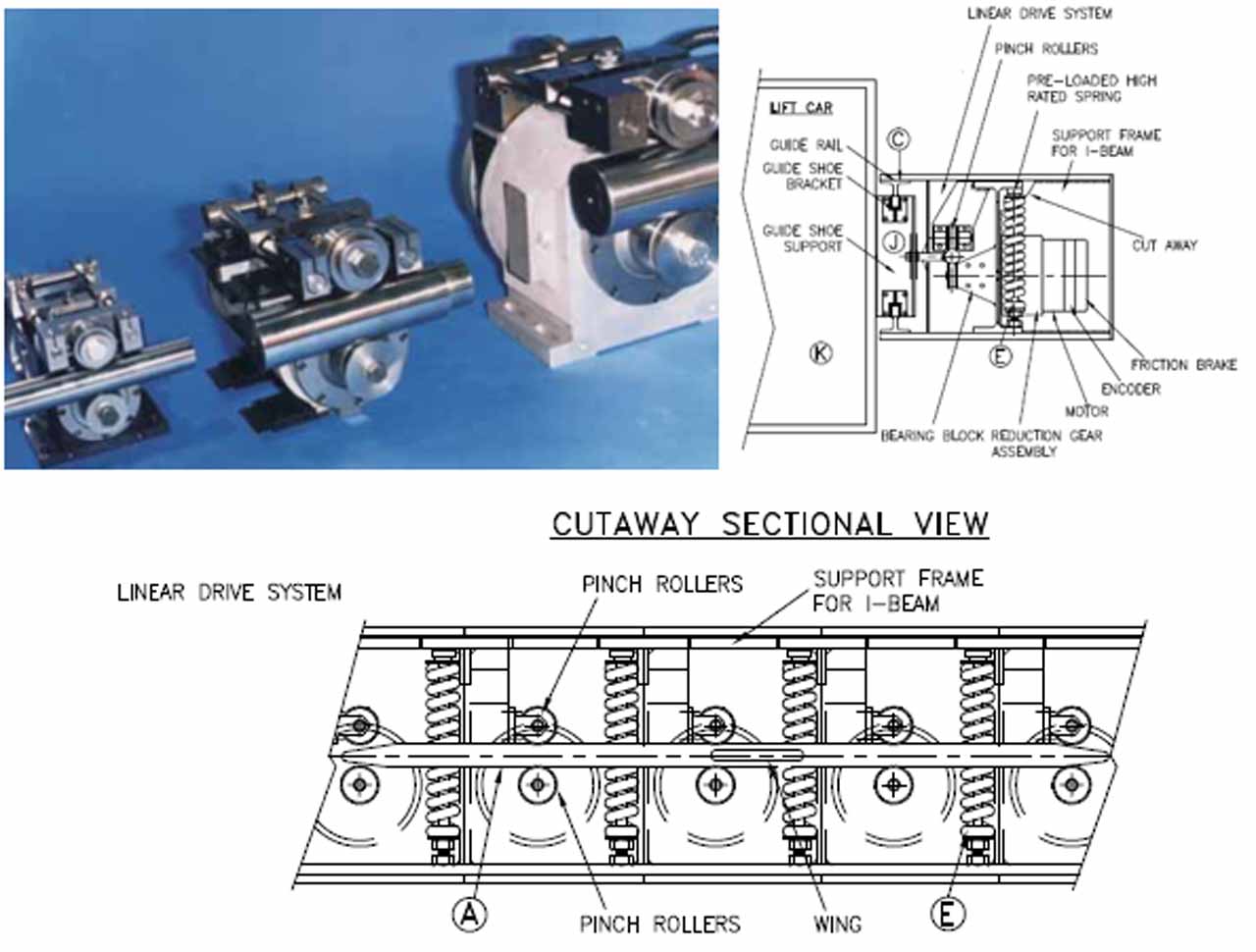

5.3 Friction Wheels on the Car

This Univator Drive Concept has two fundamental contradictions:

- Any point on the rod has the same velocity, but when the car is in acceleration or deceleration, every motor has a deferent rotary speed with each other.

- If the car travels on a curve, the curve shall have the same radius of curvature, as well as the rod.

In addition to the above two points, why is travel on a curve needed by the passengers? In which kind of buildings will it be required?

Univator is similar, with a curved friction wheel lift, but for the ropeless lift, the friction wheel should be mounted on the two sides of each lift car instead of the linear motors all the way up/down the one-way lift shafts.

7. Conclusions

- I personally believe, under current circumstances, ropeless lifts are infeasible. Only if and when new materials occur, such as super magnetic, superconductor, super battery or super capacitor, the ropeless lift may be possible. If a very small — but very powerful — motor is invented in the future and can be directly mounted on the cabin, then it would be possible to realize the ropeless lift. Just like the MRL lift, a way to locate a gearless PM motor directly in the shaft to eliminate the machine room as the result of the invention of the PM motor.

- The power transmission will be via electricity. An electrical counterweight should be used on the device when the cabin is moving down or braking. The motor will generate electricity to be saved in the super battery or capacitor.

- A wheel-less car is not the vehicle. It will be a hovercraft or aircraft, so the ropeless lift or counterweight-less lift may be just a kind of aircraft but has a name such as “airlift,” which is similar to airbus, where airbus is not a bus.

- Any mechanical product has its own physical limitation, such as “Trees don’t grow to the sky,” which is a German proverb that is translated from “Bäume wachsen nicht in den Himmel.” Current building technology may not be able to build skyscrapers higher than 1,000 m because the self-weight may collapse the building itself.

- Never challenge the limitation because the outcome is not in proportion with the input when approaching the limitation.

8. Author’s Note

Customer need is the biggest driver of innovation, but customer need is also driven by PPR (price-performance ratio) or ROI (return on investment). I oppose the idea of “for innovation to innovate.” Without a customer need, any innovation will be science fiction. This is why Elon Musk’s SpaceX is successful, while British billionaire Sir Richard Branson’s rocket company Virgin Orbit has filed for bankruptcy in the U.S. after failing to secure new investment.

Finally, I would like to share a quote of Steve Jobs with my colleagues who are still involved with the ropeless lift development: “Sometimes when you innovate, you make mistakes. It is best to admit them quickly and get on with improving your other innovations.”

References

[1] TRIZ – Wikipedia

[2] Quality function deployment – Wikipedia

[3] Adrian Godwin. MMLS: The Future of Vertical Transportation for Tall Buildings. Adrian Godwin, 7th Symposium on Lift & Escalator Technologies

[4] Adrian Godwin. Latest Trends in Vertical Transportation Design and Bim (Adrian Godwin Lunch time CPD)

[5] Hongliang Liang. China Elevator, October 2018 in Chinese; Elevator World, August 2020 in English, and Elevator World Middle East, Q4 2020 in Arabic and English.

[6] Friction wheel – Coasterpedia – The Roller Coaster and Flat Ride Wiki

Get more of Elevator World. Sign up for our free e-newsletter.