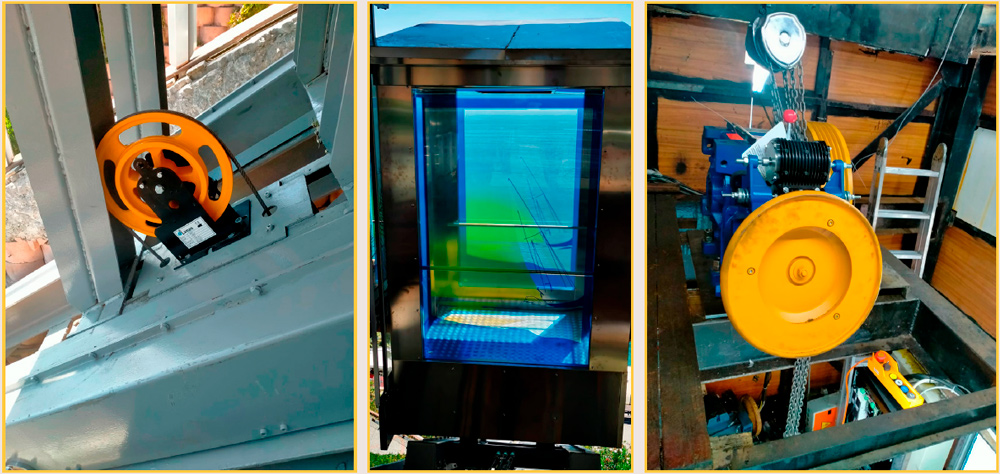

A 13-year-old inclined lift that improves access to the sea for the residents of Rose Marine — a magnificent seafront location in the Büyükçekmece district of Istanbul — is now safer and more comfortable.

Undoubtedly, the Büyükçekmece district is one of the places where you may enjoy the sea and holiday ambiance after the hectic pace of daily business life in Istanbul. The Rose Marine Project, which consists of 434 residences on an area of 29 thousand m2 and constructed by Gül İnşaat in 2008, is a truly unique project with its own seafront. But, after 13 years of use, the location’s inclined lift, which was built to maintain access to the shore due to the elevation difference of the project, could no longer satisfy visitors’ needs.

The management of the building complex met with Vadi Asansör, which already undertakes the annual maintenance of the elevators within the building complex, and asked for a revision of its elevators. Murat Kargı, general manager of Vadi Asansör, made preliminary estimates to complete this comprehensive revision project, and decided to work with Volkan Emir from Elixiva Asansör, experienced in inclined elevators in Turkey. After examining the design and physical features of the whole project, they set a roadmap for modernization.

Modernization

Corrosion was one of the main problems with this outdoor elevator, which has been serving at the seaside where it has been exposed to wind, humidity and sea salt. As it was not built with weather-resistant equipment, the unit requires a complete revision after 13 years. When removing the old equipment, Valley Asansör team had to face many challenges, such as cutting rusted screws. Murat Kargı made the following statement about the difficulties they experienced:

“We put a great effort for correcting the engineering mistakes of the construction. Finally, we reached an acceptable stage, thanks to our perfectionist approach. The cabin was very important, as it had to resist all natural and seasonal conditions, such as extreme hot and cold weather, rain and wind. First, we wanted to keep all parts we could, but when we disassembled the unit, we saw many parts were completely corroded inside. As the elevator is at the seashore, salt and water carried by the sea and wind caused corrosion and made the unit unusable. At the end, there was nothing left except the main carrier rail construction and the counterweight frame.”

Although the team wanted to replace the main rail construction and the counterweight frame, the budget allocated by the management of the building complex did not allow it.

Production and Components

Top-quality domestic manufacturers were favored for components such as rails, ropes and safety gear. Italian Alberto Sassi’s drive motor, which is frequently used in inclined lifts, was used. Components, like the cabin, frame, door and control panel, were developed and manufactured by Vadi Asansör and Eliksiva Asansör.

Cabin

As the panoramic cabin will be exposed to sunlight during the whole day, an innovative design was needed in order to eliminate the “aquarium effect.” Therefore, in addition to the required ventilation openings, the cabin is completely made of stainless material and glass. The team got in touch with Kağıttan İşler for the cabin glass and, thanks to the technology developed by the company, the light coming into the cabin has been reduced by 50%. As a result, harmful UV rays of the sun have been filtered and the inner temperature has been kept under control. The glass, which was produced for higher safety, also passed the pendulum tests. Landing and car doors, including their mechanism, have also been specially developed by the team for this project.

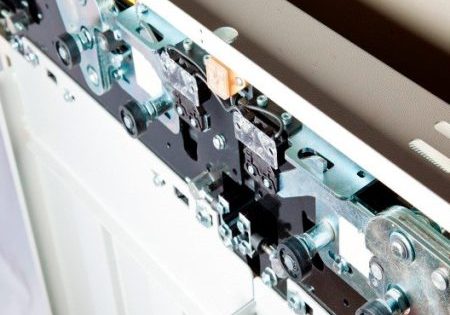

Framework and moving parts

The cabin frame was designed modularly. In inclined lifts, as the cabin is only fixed from the bottom, there is no outer frame that surrounds and supports the cabin. Therefore, the team made a special engineering study and equipped the unit with an overload system with the highest precision. This extraordinary engineering study has been developed by Vadi Asansör and Eliksiva Asansör.

Control Panel

Just as the other components, the control panel was also developed for this project. A special high-technology panel was designed unconventionally, with STO and SIL2 remote access certificates and without any contactors, moving parts or fuses, developed by Elisiva Asansör. Through this means, any problem or emergency that may occur with the inclined elevator, which is monitored by remote access, will be observed simultaneously.

This tough but enjoyable project was completed and delivered in three months.

Get more of Elevator World. Sign up for our free e-newsletter.