Safety Has Been a Driving Force for Columbia Elevator from the Beginning

Nov 1, 2013

As our country wound down from World War II, the recently immigrated Blaiotta family suffered its own tragedy when its patriarch died in a 10-story fall while repairing a construction hoist in New York City (NYC). And so, when the patriarch’s orphaned son went on to forge a multigenerational involvement with the elevator industry, it was with a continuing sensitivity to, and focus on, safety, that persists today. This safety-mindedness is evident in the products developed over the years by the Blaiottas’ company, Columbia Elevator Products Co., Inc., and the principals’ activities in the industry.

Louis Blaiotta, Sr., Columbia’s founder and current board chairman, served on the advisory board of NAESA International and has, for decades, been an active participant in the American National Standards Institute (ANSI)/American Society of Mechanical Engineers (ASME) A17.1 Elevator & Escalator Safety Code Writing Authority. He served on the Main, Hoistway and Code Coordinating committees until 1995, when he was elected to a lifetime honorary membership on the ANSI Main Committee. Blaiotta is a charter member of the ASME Qualified Elevator Inspectors Committee, and, for over two decades served as chairman of Codes and Standards for the National Association of Elevator Contractors. He is a former member of the National Fire Protection Association. Blaiotta’s son, Louis “LJ” Blaiotta Jr., Columbia’s president, is a member of the ASME Hoistway Committee and the NYC Department of Buildings Elevator Advisory Committee.

Since Columbia was founded in the mid 1960s, a deep concern for safety has driven its many innovations. Early on, Columbia developed a “knocked-down,” bolted elevator entrance as an alternative to the then-common, fully welded units. Although a side advantage was that it was easier and boasted cost-efficient shipping, its primary objective was to provide a much safer installation environment. By avoiding the precarious handling required by unwieldy pre-welded entrances, this type of entrance was much easier and less dangerous for mechanics to install on site. During these early years, Columbia also developed a fascia hooking system that holds components in place for mechanics for safer adjustment and installation.

In the cab, Columbia was the first to develop a car top made of multiple parts, rather than being a single unit, circumventing the possibly dangerous process of hoisting a large, heavy, one-piece ceiling overhead, then attaching walls. With this innovation, mechanics could first put the walls in place, then easily and safely install a sectional ceiling. As an additional safety measure, Columbia’s Emergency Exit Power Cut-Off Switch is placed inside the strike/catch pocket to ensure the elevator would run only with its emergency exit closed and locked. This unique design allows for the quickest removal and elimination of the emergency exit.

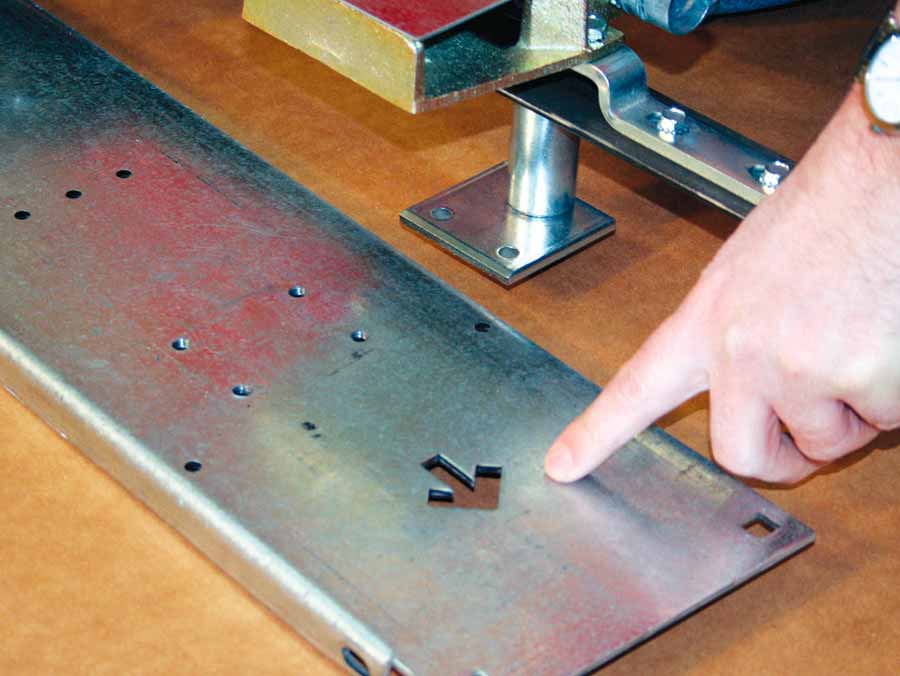

Along those same lines, Columbia developed technology for installing multi-piece, rather than single-piece, cab walls. The use of steel shell

panels was widely adopted, but Columbia developed a safer fastening system. This new “bolt-less” system allowed for safer installation of walls from inside the cab, rather than requiring the mechanic to squeeze between cab and shaft walls to fasten wall panels together. This innovation led to a patent for Columbia under the name of InstaFast®.

Blaiotta, Jr. stated:

“InstaFast is Columbia’s technology for instantly fastening elevator cab components without the need for bolts. This is accomplished by bending a male joint into the end of one elevator wall (or ceiling) panel and female joint into the adjacent panel, instantly engaging them without additional fasteners. The joints themselves secure the panels together — much faster than the traditional, century-old process — with just a few screws securing the wall panels to the floor below and some bolts to attach the canopy above. All screws are accessible from the inside of the cab, while the panels are sized and sufficiently light to easily fit through an existing opening without the need to open existing corridor walls.”

Another Columbia innovation, QuikCab®, embodies an adjustable, “floating” base that enables field adjustment upon installation. It allows for the subsequent installation of wall panels and is safer, because it is much easier to square and secure all components, then install the ceiling in pieces.

A more recent Columbia development is the QuikEnt®II (QEII) entrance system. While providing many labor- and time-saving advantages, the system was engineered with installation safety in mind. Conventional entrances required handling many long and cumbersome pieces in the shaft. More recent “stackable” entrances called for putting together the bulky/heavy subassembly (struts, header and sill assembly, also known as “roughs”), plus leveling and plumbing it, in the shaft. QEII, however, features an adjustable, grout-retaining and sill support system that can be easily set, plumbed and trued in the shaft, by one mechanic, after which the rough can simply be dropped into place. The rough can be precisely positioned, providing for a safer, less-cumbersome installation. An additional safety feature is QEII’s two-piece header, which, in addition to being unhanded, does not require mechanics to lift and manipulate the heavy track unit. Instead, with QEII, the mechanic can, on the floor, mount the track directly to the header, then lift the assembly onto the proprietary “shelf” in the strut. This notched shelf holds the assembly in place, while the mechanic bolts together the two-piece header.

While most elevator safety issues are mandated by code, Columbia has, in several cases, gone beyond code requirements. Blaiotta, Jr. explained:

“For example, our proprietary sill designs feature our bottom-of-door-upthrust retainers. As opposed to conventional sills made with simple, rectangular door-tracking grooves, our sills are engineered with a mushroom-shaped groove that uses a bushing to capture the nylon shoe guides in the track, anchoring the bottoms of the doors. If the doors are vandalized or accidentally struck with force, this system helps prevent the doors from swinging freely and separating at the top, averting a highly dangerous opening to the elevator shaft. While developed first and foremost for its safety aspects, this system has some nice side benefits: more wriggle room for less friction [and] wear and tear and longer life of the door gibs, plus, because of the expansive space in the groove, less door jamming due to accumulation in the track of cigarette butts and other refuse.“Safety considerations enter into every aspect of our products. From knock-down entrances to multi-piece car tops, to floating cab bases to door-anchoring cab sills, our safety protocols address the entire elevator, from top to bottom!”

Get more of Elevator World. Sign up for our free e-newsletter.