Sematic Elevator Door Equipment: Energy Conservation in the Elevator Industry

Feb 1, 2012

An in-depth look at Sematic’s energy-efficient door-drive controllers

Energy conservation is a current hot topic and one of the main challenges for the 21st century. Lowering and optimizing power consumption is a must in each sector and should be a primary objective when designing new products and systems. The objective of 20% power reduction by 2020 is a concern of the European Commission and can secure 50% of the necessary reductions of CO2 emissions. Energy consumption in buildings represents 40% of the overall global power consumption, most of which is due to inefficient heating and lighting systems. Therefore, it is easy to imagine how large the impact can be, even from small energy-efficiency improvements.

Energy regulations have been developed, particularly the 2002/91/EC Directive on the Energy Performance of Buildings.

Elevator power consumption is estimated to account for 3-8% of overall building power consumption, making it crucial for the elevator sector to respond. An international standard is in development (ISO 25745), while local regulations appear, such as the German VDI 4707 standard, which is a pioneer in that it laid the foundations for the ISO standard and working-group activities.

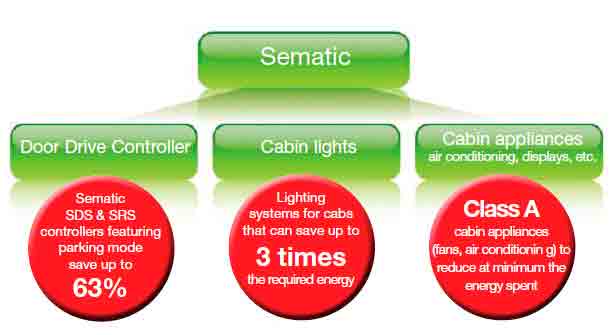

Sematic’s Approach to Energy Savings

Improvements in this field can reduce costs, increase competitiveness and improve customer welfare. During Sematic’s 50-year history, it has designed and developed a set of technological devices and recommendations that allow its elevator components to use minimal energy to help reduce a building’s power consumption. Among Sematic’s energy-efficient elevator components are its door drive controllers.

Door Drive Controllers

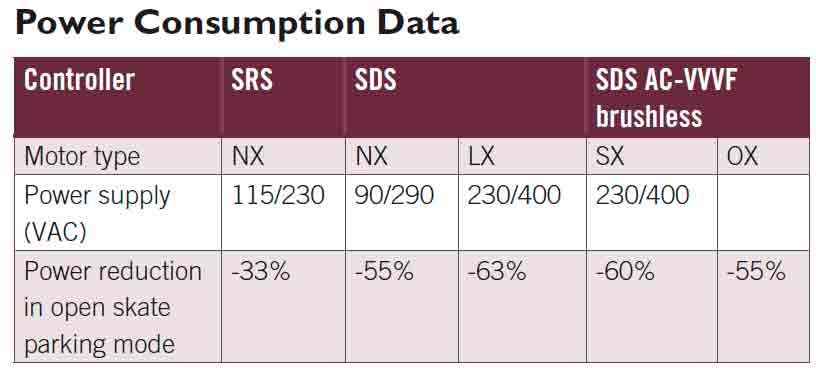

Sematic’s SDS and SRS door drive controllers feature a series of options contributing to reduced energy consumption of the entire elevator system. Parking mode, switching power-supply units, soft degradation and quick restart functions can all contribute to an elevator’s energy efficiency.

Parking Mode

“Parking mode” is an integrated function of Sematic SDS and SRS controllers that can save up to 63% of the energy consumed in standby mode. To reduce energy spent when the car is parked, it is necessary to leave the skates in the pen position. Once set, this function activates after a certain idle interval (300 s by default yet adjustable).

Switching Transformer

Sematic’s door controllers host integrated switching power-supply units featuring energy savings of more than 95%, a significant improvement compared to traditional technologies that reach only 80%.

Soft Degradation

If the system operates under critical conditions such as excessive friction of components or deformation, the door controller automatically lowers the speed profile. This performance optimization results in efficient use of energy and remains active until the proper conditions are restored (soft degradation at overload). The same occurs when the doors are completely open/closed: the controller searches for the minimum current to maintain them in the open/closed position, ultimately reducing the energy spent to the minimum required (soft degradation in stationary conditions).

Controller Quick Restart

Energy savings can also be obtained from the elevator’s main controller; for example, when shutting down all the systems after a certain idle period (particularly useful at night). In such situations, power consumption is minimal. However, the next startup of the system will require an amount of time typically unacceptable under normal operation. Sematic door controllers are capable of restarting within a matter of seconds, allowing the doors to operate instantaneously when the main controller is ready.

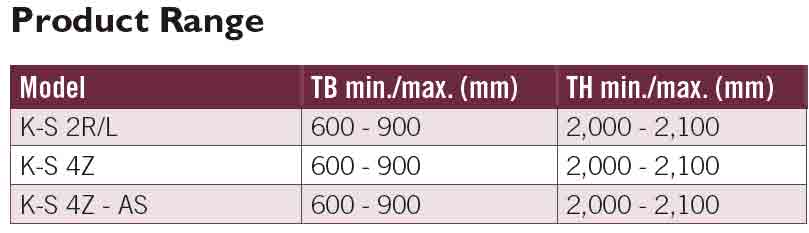

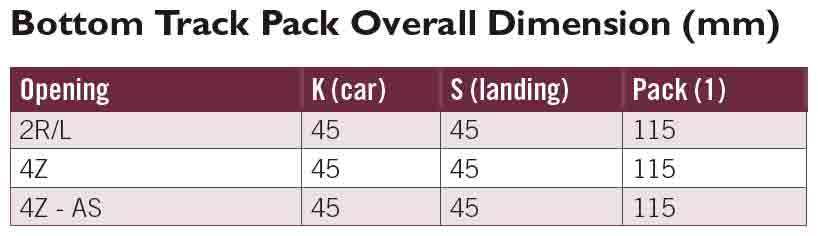

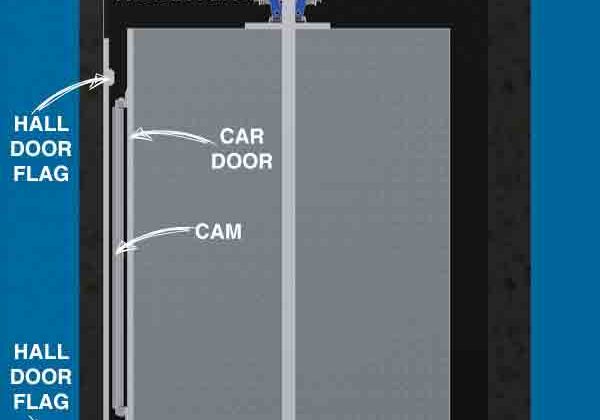

Sematic 2000 T for Modernizations with Reduced Dimensions

Sematic’s 2000 T is designed for modernizations of residential lifts installed in shafts with reduced length and depth. The 115-mm sill package (landing- and car-door sills are only 45 mm each) and reduced dimensions of both landing- and car-door headers and components allow the 2000 T to be installed in compact spaces.

The product has been designed and developed so that none of its components need to be installed in recess. This ensures that during the door installation, no additional building work is necessary, and the total capacity of the elevator system remains unchanged, allowing maximum cabin capacity.

Due to its light weight and ease of adjustment, the 2000 T is easy to handle and install, even on site. The door meets the requirements of EN 81-1/2 and can be produced in two different configurations, with (boxed version) or without (naked version) frame. For specific situations, the 2000 T can be installed in spaces with only a depth of 25 mm, allowing further space savings in the shaft. It is also available with an asymmetric opening and has the following features:

- Compact size

- Light weight for better handling on site

- 4Z asymmetric opening available

- Reduced interfloor distance (TH + 350 mm)

For more information, contact Sematic at Via Zappa Comm, Francesco, 5-24046 Osio Scotto (BG), Italy; phone: (30) 035-48-15-122; fax: (39) 035-48-15-199; or website: www.sematic.com.

Get more of Elevator World. Sign up for our free e-newsletter.