Sponsored

A forward-thinking follow-up to the 1997 EW article, which explored half the speed

by Rick Barker with contributions from Sean Morris and George Wisner

At a time when elevators were reaching 12.5 and 14 mps in Japan, an executive from Turner posed the question at a conference in 1995, “Is 2,000 Feet Per Minute Enough”?[1] While at Otis, I offered some answers in a paper by that title at another conference that year.[2] This suggested we focus on skylobbies and double-deck elevators for tall office towers, for which 2,000 fpm was enough. We, of course, learned long ago we do not need faster and faster single-deck elevators all starting from the ground.

Speed records have returned, once again from some Japanese manufacturers and again for single-deck elevators to observation (OB) decks, but this time in China with a full speed of 20.5 mps (4,035 fpm). Earlier this year, The Washington Post called the race “surprisingly cutthroat.”[3] That adverb is appropriate, as such elevators should not be viewed as a useful trend for tall buildings in general.

Update of a Detail

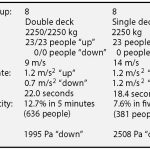

In 1995/1997,[2] it was shown that an elevator with a higher acceleration and deceleration rate, in a “race” with an elevator with a higher full speed, would arrive at the finish line at about the same time (winning by a “photo finish”). This was for a 250-m run between an elevator 9 mps at 1.2 mps2 and an elevator 12 mps at 0.8 mps2. (Figure 1). That was studied because elevators with silicon-controlled rectifier (SCR)-based drives for DC motors were still available for high-speed elevators offering shorter flight times, while elevators with improved[4] yet more costly insulated-gate bipolar transistor (IGBT)-based drives for AC motors were being offered from Japan with a reduced elevator acceleration rate.

An update is important. IGBT costs have come down and are predicted to come down further due to increased demand for automobile electrification, production from China (in an industry still led by Japan)[5] and demands to replace SCR drives as power quality becomes an issue. That said, if the costs of dealing with the harmonics for SCR drives were considered — for example, in Dr. Alexander Kusko’s study of 12-pulse SCR drives (ELEVATOR WORLD, February 1992)[6] — and/or the costs of power-quality filters were considered for nonregenerative IGBT-based drives for slower elevators (even ignoring the costs of additional machine-room air-conditioning for nonregenerative drives), IGBT and SCR drives would already be at cost parity.

The return of quicker floor-to-floor and running times would be very useful to reduce elevator requirements. This is also considering that, for local elevators in office buildings, manufacturers’ standards tend to include destination dispatching with instant car assignments at all floors (including all office floors). That reduces fixture requirements, but, in many cases, significantly increases long waits during the lunchtime peak.[7] Today, ride quality need not be sacrificed for shorter flight times, and, when it is necessary to conserve power (with already-efficient elevators), higher acceleration can be provided for less than “full” car loads going up (while 100% capacity loads in passengers are unrealistic) and so on for other load conditions.

General Update

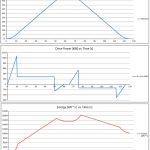

A larger focus of the 1995/1997 article[2] was to compare round-trip handling capacity for 9-mps (1,772-fpm) double-deck shuttles, to 14-mps (2,756-fpm) single-deck shuttles — both groups having eight elevators, the same cab footprint, travel of 400 m, the same acceleration and deceleration rate (going “up”) and handling an office-zone population of 5,000 people above the sky lobby. The double-deck shuttles, by far, provided greater up-peak handling capacity, even when their acceleration was reduced for the descent for aural comfort, and the same comfort criterion was ignored for the 14-mps single-deck shuttles. (Figure 2).

To provide the same handling capacity as the eight double-deck shuttle elevators, 13 single-deck elevators would be needed running to the same sky lobby, consuming much more useable space. And, if comparisons were made between a pair of elevators running to an OB deck, double-deck elevators would increase revenue potential, enable a vertical separation in the types of traffic for the OB deck and provide greater capacity for evacuation conditions.

The ear-comfort criterion was based on studies and recommendations to increase run time for the descent for very long-travel, nonstop, high-speed shuttle elevators, to stay within a calculated ear-pressure differential of 2,000 Pa, considering the rate of increase in atmospheric pressure. For our industry, this is credited to Dr. James Fuller of United Technologies Corp. (UTC).[8]

An update is also in order for power and energy. Sean Morris, a principal in our firm, compared power requirements for a 2000 kg at 20 mps single-deck shuttle elevator, and a 2000 + 2000 kg at 10 mps double-deck shuttle, both having all-steel suspension ropes, a travel of 500 m, and the same acceleration and deceleration rate of 1 mps2. The 20-mps single-deck elevator and the 10-mps double-deck elevator both require the same drive running power, about 300 kW. And, with full loads in both directions, the energy consumed is about the same (Figures 3A and 3B).

Figures 3A and 3B are based on our models, which use reasonable assumptions for equipment masses and efficiencies for tall-building elevators. Relating this to the 1995/1997 study,[2] where it was shown that similar double-deck elevators have a major advantage in handling capacity for their space footprint, we can see more deeply that speed alone is less efficient. And, if the double-deck elevators were to have a full speed of 20 mps, drive running power would double.

In our industry, 20 mps is very impressive to maintain ride quality, likely requiring active roller guides[9] to reduce horizontal vibrations, our industry’s best car designs for aero-acoustics to reduce in-cab noise levels, advanced car and counterweight safety designs with special ceramic liners (given the high frictional heat), etc. And, for very long travels when descending nonstop from an OB deck or sky lobby, a “spring-effect” of the ropes also needs to be considered for floor leveling, where solutions other than extending flight time have been shown to be effective — including drives with high-speed torque control and phase-plane landing controls, as starters.[10]

Elevators that can travel 4,000 fpm are an engineering feat but not a technology leap that is useful for many tall buildings. Similar comparisons might be made between the Aérospatiale BAC Concorde and the Airbus A380-800. Yet, for an OB deck, where a pair of shuttle elevators running full height can consume precious space in a building core, an alternative can be scenic elevators, enclosed at the tower’s exterior, slowed sufficiently and planned sufficiently clear of visible framing for building façade glass, and smart glass (with controllable cab glazing opacity) — all for passenger psychological comfort — to enjoy the view during the ride (not just the speedometer reading).

A related question also causing intrigue is, how far should a roped elevator travel, given the latest lightweight rope construction? Assuming the latest of these using a core of carbon fibers by KONE proves successful (where others using aramid fibers including Kevlar® have not), including the overall rope construction for tall-building elevators, there are advantages. Still, longer travels for a single-roped elevator are not the “holy grail.” For a given roped elevator, the longer its travel, the longer it takes to return, where, to handle a given traffic demand, you need more elevators and hoistway space. Lightweight ropes have long been sought to allow a roped (including a double-deck) elevator, to travel higher for a given or limited set of elevator components (e.g., machines, drives, safeties), so a successful solution will be helpful.

Updated Prediction

The intrigue with speed more seems to beg the questions, where do we focus our engineering efforts for tall buildings, and, what types of buildings are needed? For the challenges of urban China, two architect-authors propose the “Vertical City: A Solution for Sustainable Living.”[11] The cities consist of multiple supertall towers connected/braced by skybridges, with common areas and green spaces, aligned at tower skylobbies. Our industry can satisfy a desire for the fastest or longest-travel elevator, but some urban areas may soon need more comprehensive solutions.

The sky lobby will remain an important element. It has long been an efficient solution for high-occupancy tall office towers, with many examples in the 100-story range utilizing high-capacity, double-deck, sky lobby shuttle elevators — for example, in the Willis Tower built years ago in Chicago. Of course, an entire vertical city would require vertical transportation that is very high capacity and space efficient with very extended elevator travels.

Your author believes we should focus on adequately sized “ropeless” sky lobby shuttle elevators with multiple independent cabs in the same hoistway paths as part of an overall system of local lifts, which can be the abundance of standard roped elevators we have now. Such a solution would be beneficial today in tall office towers (and, later, in vertical cities). An interim roped “step” was the Otis Odyssey™ system I presented in 1997[12] that included the ability to move cabs horizontally off and between car frames of connecting shuttles to transport the cabs higher and higher and accommodate off-line loading areas at sky lobbies.

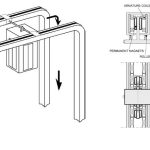

Yet, looking back, I often think many of us failed to fully absorb a 1994 article by Toshiaki Ishii of Mitsubishi Electric[13] summarizing the key parts of a practical ropeless elevator with permanent-magnet motor concepts — now covered in detail in a book co-authored by Jerry Piech of UTC/Otis on linear synchronous motors (LSMs) that includes elevator applications (Figure 4).[14]

George Wisner, Barker Mohandas LLC Technology Director, sees the magnetics as requiring the greatest focus in reducing costs for LSM ropeless elevators. The elevators would actually utilize today’s IGBT-based power electronics drives. And, looking ahead for these drives in general, the emerging technology of silicon-carbide semiconductors (SiC) will most likely eventually benefit all elevators, with improved performance via lower losses and higher switching frequencies. SiC costs will, of course, be higher initially as these semiconductors are fully developed, etc.

Sean Morris roughly modeled power and energy, comparing a ropeless and a roped elevator, both 1800 kg at 10 mps with a travel of 600 m. Ropeless elevator drive running power requirements were found to be roughly four to five times that of the roped elevator (600 kW versus 130 kW). This was actually an improvement over some old estimates, which may have assumed less-efficient linear induction motors. We assumed that car weight would be reduced to a factor of two times elevator capacity (compared to four times for the car structure necessary for a 600-m elevator with all-steel suspension and compensation ropes). Experts in certain applied-materials fields might examine the validity with carbon-fiber composite grid structures. Still, the ropeless car regenerative running power was about 330 kW, compared to just 60 kW for the roped elevator, where with average loads, we might start to say a ropeless car consumes “only” twice the energy.

For simplicity, we did not examine some ideas we have had for at least a decade, such as a hybrid option for energy assistance. “Imagineering” readers might guess at what those might be, like utilizing gradual rope-gripping devices similar to those on some automated people movers (APMs), here acting on a full-travel rope loop — not unlike a San Francisco cable car — yet not using the rope loop for propulsion or suspension and also capturing supplementary power generated via the rope sheaves. However, in the context of the space and construction saved in a tall building by having multiple shuttle cars in the same hoistway, some numbers already suggest there is motivation for increased engineering efforts and that more complex options could follow.

Still, the technologies need be applied with techniques to comprise a vertical transportation system for overall efficiency. Not unlike the Otis Odyssey system, we would want the shuttle elevator cabs to be able to move horizontally off from elevator bogies, carriers or platforms, sometimes to off-line loading areas or the bogies of APMs. However, fundamentally in a tall building system, there are many advantages in having sky lobby shuttle cabs return down a different hoistway or path, and planning both abilities at every sky lobby.

In 2003, we found an equivalent dispatching concept very useful for a group of roped shuttle elevators for a supertall project called Al Burj in Dubai. We later applied this same concept to the Nakheel Tower, also planned for Dubai. We planned a group of single-deck shuttle elevators serving multiple residential sky lobbies, where passengers would transfer to local passenger elevators (which did not have express zones and had speeds slow enough to allow their hoistways to be stacked on top of each other for further space savings). For the shuttles, we called the concept “sky lobby destination dispatching” (Figure 5).

Figure 5’s “spatial plots” are from dispatching simulations for a group of six roped shuttles, 1800 kg at 9.0 mps (average) at 1.0 mps2, traveling 520 m, stopping at four sky lobbies (SL4-SL7) serving 700, 600, 530 and 330 people, respectively. Two-way peak traffic was simulated. An average speed was used, considering some speed reductions for ear comfort. By reducing average stops and run distances, sky lobby destination dispatching reduced average waits, long waits, car loads and main lobby queues to the point a very expensive shuttle elevator was saved.[16]

Essentially, the same dispatching concepts would be applied to ropeless sky lobby shuttle cabs. Passengers with common sky lobby destinations would be directed to particular departing cabs, which, after their highest assigned demand, would move horizontally, then reverse direction and return. Again, average stops and run distances would be reduced, reducing average round-trip time and increasing efficiency. This is in addition to the fundamental advantage of sky lobbies where passengers transfer to local elevators, avoiding delays in shuttles. Off-line loading areas at sky lobbies can help, while, based on experience, passenger transfer times under different scenarios need be compared to the time to slowly move cabs horizontally for rider comfort.

thyssenkrupp is taking a step with the parts and the system, while the initial version appears to involve only ropeless elevators in a loop system with relatively small cabs.[17] As your author said about the effort (when asked about its R&D program leader being recognized as an Engineering News Record Top 25 Newsmaker), “Markus [Jetter] has, in fact, led an R&D effort across the threshold to the untethered Holy Grail of the elevator industry, which will strongly benefit buildings in general.”[18]

While we are not endorsing the particular approach, when a large elevator company commits to LSM rope-less elevators, with the ability to move cabs horizontally, and they have experience gained from Transrapid (a joint venture of Siemens and thyssenkrupp for the Shanghai Maglev Train), it is all quite noteworthy. It should also be recognized that some Japanese elevator manufacturers were the pioneers of ropeless elevators at least two decades ago and actually built some prototypes. Also, MagneMotion in the U.S., now part of Rockwell Automation, actually built a linear synchronous ropeless elevator for the U.S. Navy.[19]

We hope such efforts increase and include a scaled-up sky lobby shuttle version for tall buildings, as described in this article. Going back to the “Is 2000 fpm enough?” question when I first heard it in 1995, Alfred McNeill and Doug Bennett of Turner also said, “We need new elevator technologies to get rid of all those cables.” The technology has long been here, and it is being improved all the time. It’s more a matter of some techniques and support from more companies in our industry that’s overdue. And, if that does not change, given the different design elements required, our industry could easily lose this opportunity to another field.

- Figure 1: Remodeling of simplified graph shown as Figure 5 in “Is 2000 Feet Per Minute Enough?” (EW, March 1997), here showing transitions due to jerk rate that is 1.6 mps3 for the 12 mps elevator, and 2 mps3 for the 9 mps elevator. Run times are 36.8 and 36.4 s, respectively.

- Figure 2: From “Is 2000 Feet Per Minute Enough?”

- Figure 3A: Drive power and elevator energy, two-stop double-deck shuttle elevator, 2000 + 2000 kg at 10 mps at 1 mps2, 500-m travel to sky lobby

- Figure 3B: Drive power and elevator energy, two-stop single-deck shuttle elevator, 2000 kg at 20 mps at 1 mps2, 500-m travel to sky lobby

- Figure 4: Ropeless elevator diagrams courtesy of Zbigniew Piech from “Linear Synchronous Motors — Transportation and Automation Systems” used in a chapter in the “Technology” section of Vertical City: A Solution For Sustainable Living. Your author also wishes to credit the concepts to Toshiaki Ishii, Mitsubishi Elevator, “Elevators for Skyscrapers,” IEEE, 1994.

- Figure 5: From “Improved Techniques for Vertical Transport for Supertall Buildings” by Rick Barker, Barker Mohandas LLC (with contributions from Paul Bennett, Clem Skalski, Mike Spaner and George Wisner), presented at the CTBUH Conference in Mumbai in 2010