The significance of the invention of the wheel and what it has meant to industrial development has rarely, if ever, been debated. Without it, we would be a relatively stagnant species, unable to stray too far from where we were born. And, the accomplishments in manufacturing, as well as in transportation (both on land and in the air), would not have come to fruition were it not for a means to literally get things rolling.

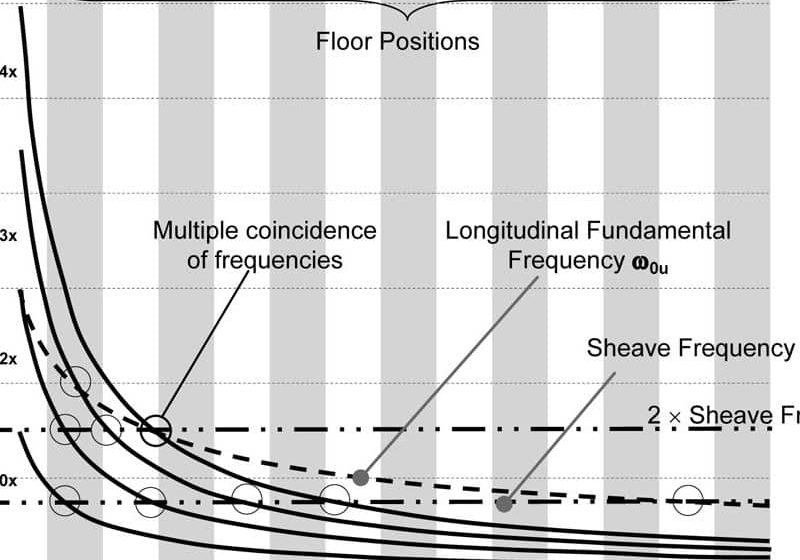

In our industry, wheels are used as elevator guides and have made it possible for elevators to be designed to travel at great speeds and to extreme heights. Addition-ally, if it was not for the sheaves, which are essentially grooved wheels, in elevator traction machines, our industry would have had the ability to design, manufacture and sell equipment that served buildings of only a few stories in height. We would not have been able to build much of a high-rise industry without using sheaves and roller guides in vertical-transportation equipment.

In the June issue of ELEVATOR WORLD, we included articles and reports on roller guides and the rails on which they travel. This month, we have included a special section on another elevator component that has also allowed elevator engineers to take our industry to even greater heights – wire rope.

Advancements in the design and manufacturing of steel-wire ropes have made it possible for elevator system designers to develop elevators that can readily operate at thousands of fpm and travel to significant heights. Some of the super tall buildings that have been built during the last decade contain elevators that run-in excess of 2,000 fpm and rise to nearly 3,000 ft. above the ground. This would not be possible were it not for suspension means that can withstand the rigors of tension, compression and continual flexing, while supporting many tons of weight and doing so for many thousands of elevator trips. Wire ropes have allowed elevator engineers to take elevators to heights that our industry’s founders never imagined possible.

This month’s articles on wire ropes should give EW readers a renewed appreciation for the component that makes it possible for elevators to run continuously, often-times in harsh construction environments, thereby making the construction of tall buildings a reality instead of just a dream. These ropes must not only be properly applied, but also carefully stored on construction job sites and handled carefully during an elevator’s installation to get the full life and, therefore, benefit from the marvelous component known as a wire rope.

The next time you are gazing down from a high-rise building or observation deck, remember the special topic you read about in this month’s issue of EW, and consider that it was not only the fancy cab and the sophisticated computerized control equipment, nor even the huge hoist machine that got you up there. It was also the steel-wire ropes that made your journey safe, comfortable and convenient.

We’ve discussed two of what I feel are three significant devices that have made the technological advances in our industry possible throughout the last century. And as important as the first two devices are, it is the third device that I feel has really made advanced equipment designs possible, not only in our industry but in most others as well. It is a very simple and elegant device that is usually within easy reach of most people while they are at work. Without this third device, designers in all industries would not have been able to bring their ideas and schemes to life. For now, I’ll keep the answer to myself and let you all think about it for another month. In the meantime, feel free to e-mail me at [email protected] with your thoughts on what you feel this last item might be.

It may take some thinking to figure out what I am refer-ring to as being such a significant design aide. However, I am confident that when I reveal it, most will agree with me on what I feel is this third significant invention.

Get more of Elevator World. Sign up for our free e-newsletter.