Smart, Fast, Energy Efficient

Apr 1, 2017

Otis Turkey installs double-deck elevators with record-breaking speeds in Istanbul high rise.

by İpek Akyıldız Sipahi and Onur Artıkoğlu

For Levent 199, a 40-story office building in Istanbul’s financial district, Otis Turkey delivered a double-deck elevator system that is remarkable for its speed, safety and energy efficiency achieved by, among other measures, drives that recycle energy. The system treads lightly on its surroundings, with the double-deck configuration reducing core space, thereby providing the building owner with more leasable space. The system also uses a controller that reduces the need for hoistway wiring.

Prior to this installation, Otis Turkey already had some of the fastest elevators in the country in the Isbank, Kanyon and Istanbul Sapphire projects. Now, it has improved on its own record by 1 mps with the elevator system for Levent 199. The double-deck cars that run at 7 mps are the fastest elevators in Turkey, organizing the building’s traffic flow in an efficient manner with the CompassPlusTM destination-dispatch system.

The double-deck elevators increase the system’s capacity by running two cars in a single frame in the same shaft. Having both upper and lower decks in the same hoistway enables service to two consecutive floors simultaneously. The company observes:

“The value Otis added to both the project and end users opens another phase in developing Turkey’s construction business. The double-deck system with CompassPlus destination dispatch has triggered similar applications and given designers and developers flexibility for their vertical-transportation systems. With speeds of 4 and 7 mps and capacity of 2500 kg, Otis has introduced a revolutionary car design that is both stunning to observe and exhilarating to experience. These are not only fast elevators, but quiet and smooth. Such an impressive performance derives, in part, from the analysis of platform, ceiling and ventilation components, but also from the aerodynamics of the car.”

There are two different lobbies for odd and even destination floors. Upper and lower lobbies provide well-organized lobby areas and improve performance. At the building’s entrance, restrictions are highly visible and understandable. With the help of directional signage, users are directed toward the lower car for even floors and the upper car for odd floors. Passengers headed to odd floors are directed to an escalator in the upper lobby.

The System: A Closer Look

Five double-deck units serve only the low zone, traveling at 4 mps from the ground and first levels to the 22nd and 23rd floors. Another five double decks serve only high-zone floors between 22-23 and 40-41. There is an express zone for travel to the 22nd floor for the fastest double-deck elevator, which travels at 7 mps. In addition to the passenger lifts, each with a capacity of 2800 kg, there is a fire/service lift with a capacity of 2000 kg and speed of 3.5 mps, 12 Gen2® machine-room-less elevators and six escalators.

The CompassPlus destination-dispatch system was installed to enhance traffic flow. Minimizing long elevator queues, interim stops and extra waiting time, the system uses approximately 27% less energy than a traditional elevator system.

Each passenger inputs his or her destination prior to boarding and is assigned a specific car. The CompassPlus and building-security systems are integrated. This allows passengers to swipe their entry cards and reach their destinations without effort. Identification readers are connected directly to CompassPlus fixtures, which saves wiring costs.

The destination-management system separates the building into segments and directs passengers to the most appropriate car by also considering the number of passengers in each car. Described by Otis as “SmartGrouping,” this technology organizes travel by grouping both passengers and stops. Passengers going to the same destination are assigned to the same elevator. SmartGrouping also assigns elevators to serve groups or zones of floors.

This technology offers a smarter approach to efficient elevator management by combining artificial intelligence and fuzzy logic algorithms to reduce long waits. Passengers grouped by common, contiguous and nearby destinations wait less. During peak periods, the system continuously adapts elevator service zones to traffic demands. During lunchtime, for example, CompassPlus algorithms match “up” and “down” stops, group stops at nearby floors and create more express runs.

The CompassPlus system constantly tracks traffic flow and intensity, identifying journey patterns and peak periods, to respond to passenger demand. The system avoids wasting energy by matching resources to demand. At night, for instance, the system automatically moves some elevators to standby, because traffic is light. Fixtures automatically transition to sleep mode when not being used for a preset interval.

The touchscreen can be equipped with an optional directory function that allows the passenger to enter a destination by selecting a building tenant from a drop-down list. To improve in-car experiences, car annunciators are mounted on one side of the entrance column. These show all future destinations to help ensure comfortable boarding. For good measure, there are also information screens to show the next destination and other deck loading or unloading progress when noncoincidental stops of decks occur.

With web-based EMS Panorama, Levent 199’s management team can monitor the status of both elevators and escalators. The system enables technical staff with the proper security clearance to monitor, control, report on and manage a full range of critical operational functions from any networked computer. It can also generate a range of customizable maintenance and performance reports.

Efficiency Through Simplicity

Otis’ in-house production of a 70-T gearless machine was intended/designed to be faster and able to go higher. The machines that serve the high zone weigh nearly 13 mT. A gearless driving machine operates on a direct-drive system in which there is no reduction gear between the motor and drive (hoisting) sheave: the drive sheave is connected directly to the motor and brake. Gearless designs are used in the world’s tallest structures. They are efficient and used for achieving greater speeds.

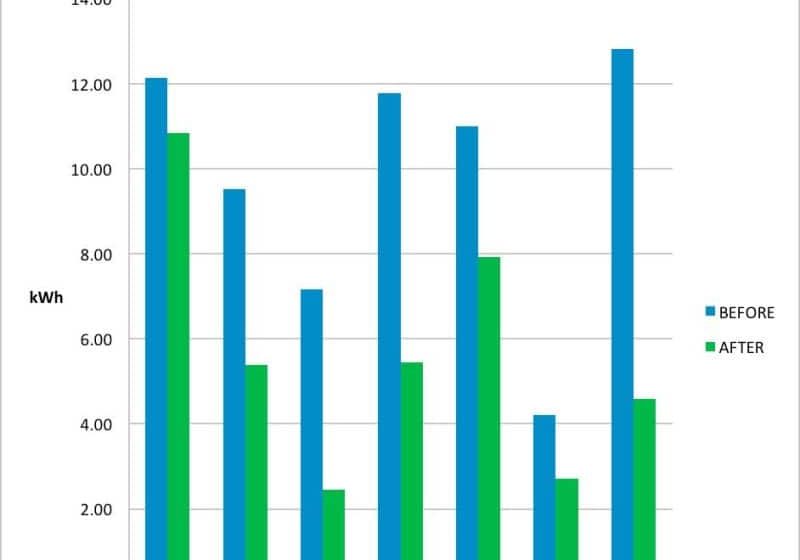

The elevator system’s regenerative drives recycle energy, rather than wasting it as heat. They reduce energy consumption by up to 65% compared to that of a conventional elevator. When power flows into the motor, it creates a lifting torque on the shaft and elevator sheave, lifting the car. When the car travels down, the motor acts as a generator, transforming mechanical power into electrical power and pumping current back into the facility’s electrical grid to use elsewhere.

Otis’ E2 controller provides motion control and safety features, while dramatically simplifying hoistway wiring. The control system continuously monitors individual safety devices thousands of times per second. Enhanced diagnostics and setup functions improve system robustness. Relays and position tapes have been completely eliminated, improving overall system reliability.

Get more of Elevator World. Sign up for our free e-newsletter.