SODIMAS Open Week 2010

Feb 1, 2011

John Gale, EW Contributor

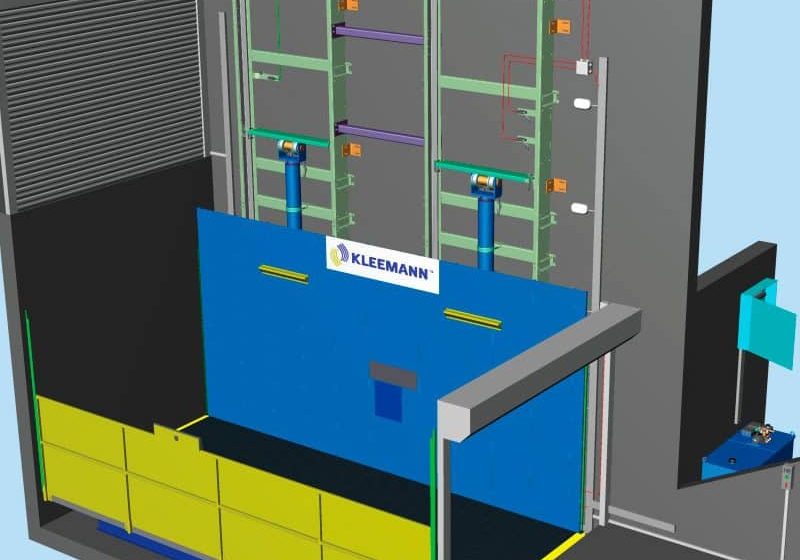

Sodimas held an open factory week at its main head-quarters in Valence, France. This facility is conveniently located alongside a key motorway network, which made for easy access for visitors. The main thrust of the event was to introduce the ‘Small Lift’ home lift to the client base. Visitors were able to ride the new system, which was dramatically sited in the Sodimas product showroom, which has become an important part of the Valence factory. The system is illustrated in this report as a group of photographs showing a number of the key elements that make up the Small Lift. At present, the lift is available as a 225-kg or 450-kg unit and can be configured as a single-opening or through-car design. The system is a belt- driven, machine-room-less with the machine and controller sited between the guide rails at the bottom level. Access to the machine and control panel is through a lockable door in the shaft or enclosure.

We can report that many clients were very impressed with the ride quality and general design layout and specification, which complies with EN 81-70 Handicapped People. It was stated during the introduction that the lift was primarily targeted for home applications of up to five stops, with a working speed of 0.5 mps and travel of about 12 meters. Running costs and efficiency of the system had been considered an important part of the project, and a 1.4-Kw gearless 230V single-phase 50/60 Hz machine had been selected for the system. The choice of a monophasic motor was taken to meet the code recommendations for home lifts and comply with the energy-saving norms. In this report, we include the layout drawing and basic specification showing the space and general requirements. It is worth drawing attention to the reduced pit depth and headroom needed, which should be a useful attribute when locating a position in the home where the system can be sited.

In addition to the Small Lift, a number of other product developments and refinements were showcased in the product room during the three-day event, which included:

- SQUARE: a new economically priced lift-car package, which in response to market research features LED lighting and allows for a limited number of wall colors and finishes to be selected.

- Telealarme and Call Center: Sodimas has introduced, with SafeLine Europe, a communications system with a three-year warranty to cover the lift-car telecommunication equipment. As can be seen from our photographs, this display attracted a great deal of interest from the French client base.

- Blue Style: Buttons and displays were also presented. In particular, a suitcase demonstration unit was dramatically lit, and we were shown that it was fitted with connections to allow a potential client to input and personalize the display to demonstrate a client’s individual project.

- Traction machines for modernization and new lift projects were strategically positioned around the hospitality area. Visitors were often seen musing over a range of gear machines with synchronous motor and permanent magnets, a large gearless machine or a number of smaller gearless units as used on the belt-driven installations in the product room.

As readers can see from our report, this event was very well attended, with more than 600 professionals attending over three days. Visitors came from Europe, Africa, the Middle East and the Far East. We asked Marcos Bravo, Sodimas export executive, for comments regarding the event, and he expressed his delight in seeing so many people attending, and whilst most of the visitors had come from France, there were many from the rest of the world. This was clearly seen when looking around the hospitality tables in the central marquee. Bravo went on to explain that the event gave the company a very good opportunity to showcase the latest lift products and design expertise, but most importantly, the company could arrange tours for visitors of the training areas, assembly facilities, test tower and design offices.

We joined a tour of the facilities led by Jean Yves Langlois, and as can be seen from the photos, we were able to visit the test tower demonstrating the V Motion Be system and a new modernization product, which uses traditional wire suspension ropes. We were informed that some clients, where a total replacement was not possible, needed a roped solution, so the company had developed this roped modernization product in response to that request. Importantly, this modernization solution incorporates the use of a traditional gear machine with synchronous motor so that high energy efficiency can be achieved.

In the training room, we were able to see technicians installing and adjusting door operators, and on the other side of the room, some of the design team were showcasing the Multiplex group control system, which we were informed had been developed greatly. We will be looking at that in greater detail next year with the designer of the system.

Back in the marquee, we were able to enjoy some refreshments, and after lunch, Patrice Arnoult took the opportunity to give credit to the design engineers, technicians and back room staff who were working hard behind the scenes and introduced them to the guests. This was a very nice gesture and was appreciated by many guests who had only heard these people’s voices over the telephone or e-mail.

On the last day, a special presentation was made, as it was the birthday of Mr. Arnoult senior, and he fittingly was able to share this special moment with family and friends, an important part of the Sodimas philosophy.

Get more of Elevator World. Sign up for our free e-newsletter.