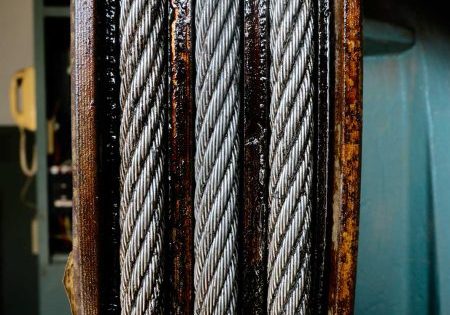

Steel ropes and chains compose the suspension means that should be used for suspending the lift car, counterweights and balancing weights in line with EN 81-20 standard. The standard defines the usage methods and criteria of ropes and chains.

Tensile strength and features of ropes are specified in EN 12385-5 standard according to their nature (fiber cores or steel cores), the classification of double and single nominal tensile strength and intended uses.

The standard states that suspension ropes’ rated diameter should be at least 8 mm. However, it should be noted that ropes with smaller than 8 mm diameter which are tested and approved by a Notified Body for the same safety requirements of 8 mm or bigger ropes can also be used in lifts. When such a rope is used, the rules and criteria of use, control and replacement, which are specified in the report by the Notified Body, should be followed.

The safety factor of suspension ropes should be at least 16 in lifts with double ropes and 12 in lifts with ropes more than double. The safety factor is the rate of one rope’s minimum tensile breaking force to minimum force applied on one rope when the car is loaded with the rated load and parked on the bottom. Forces must be in Newton (N).

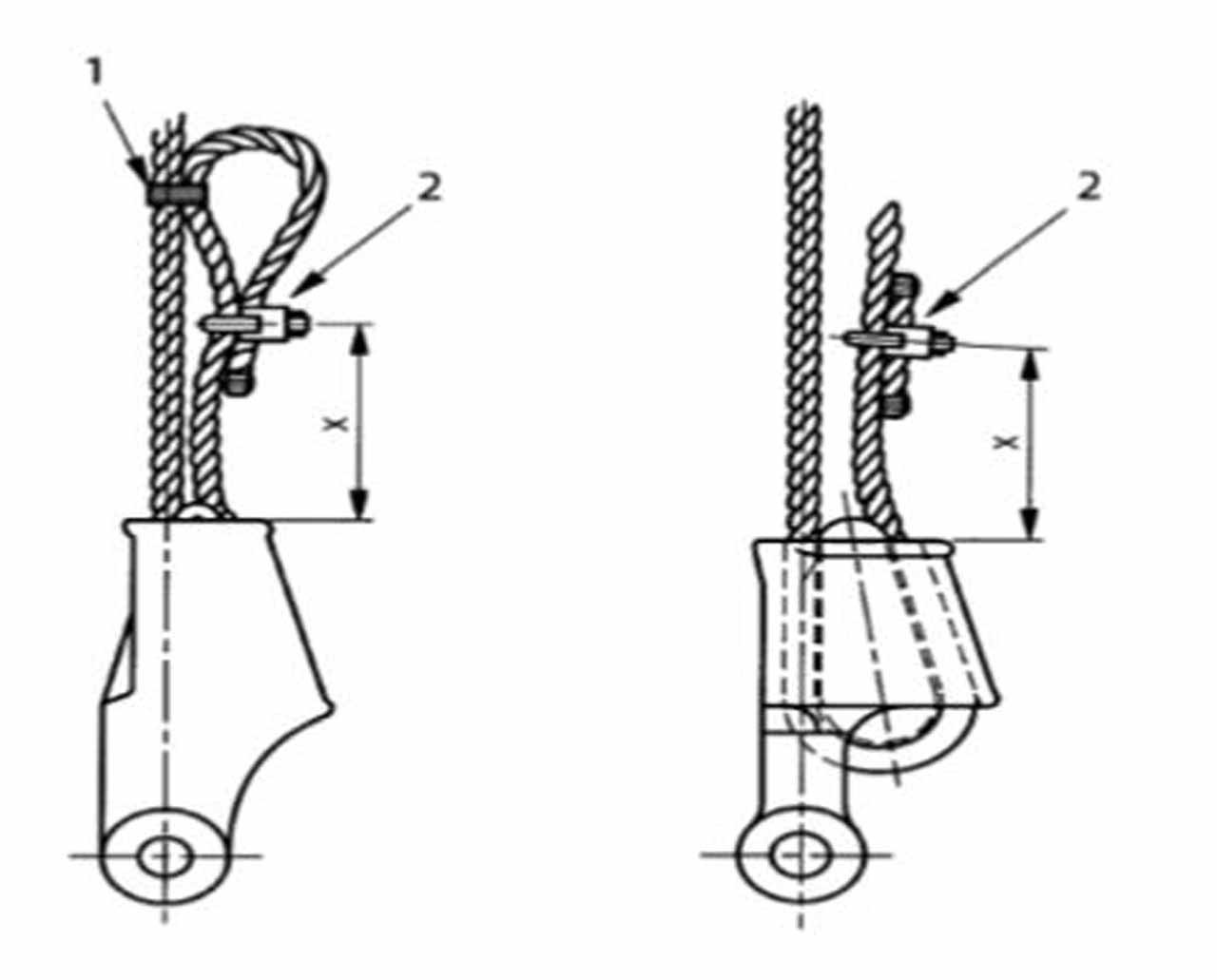

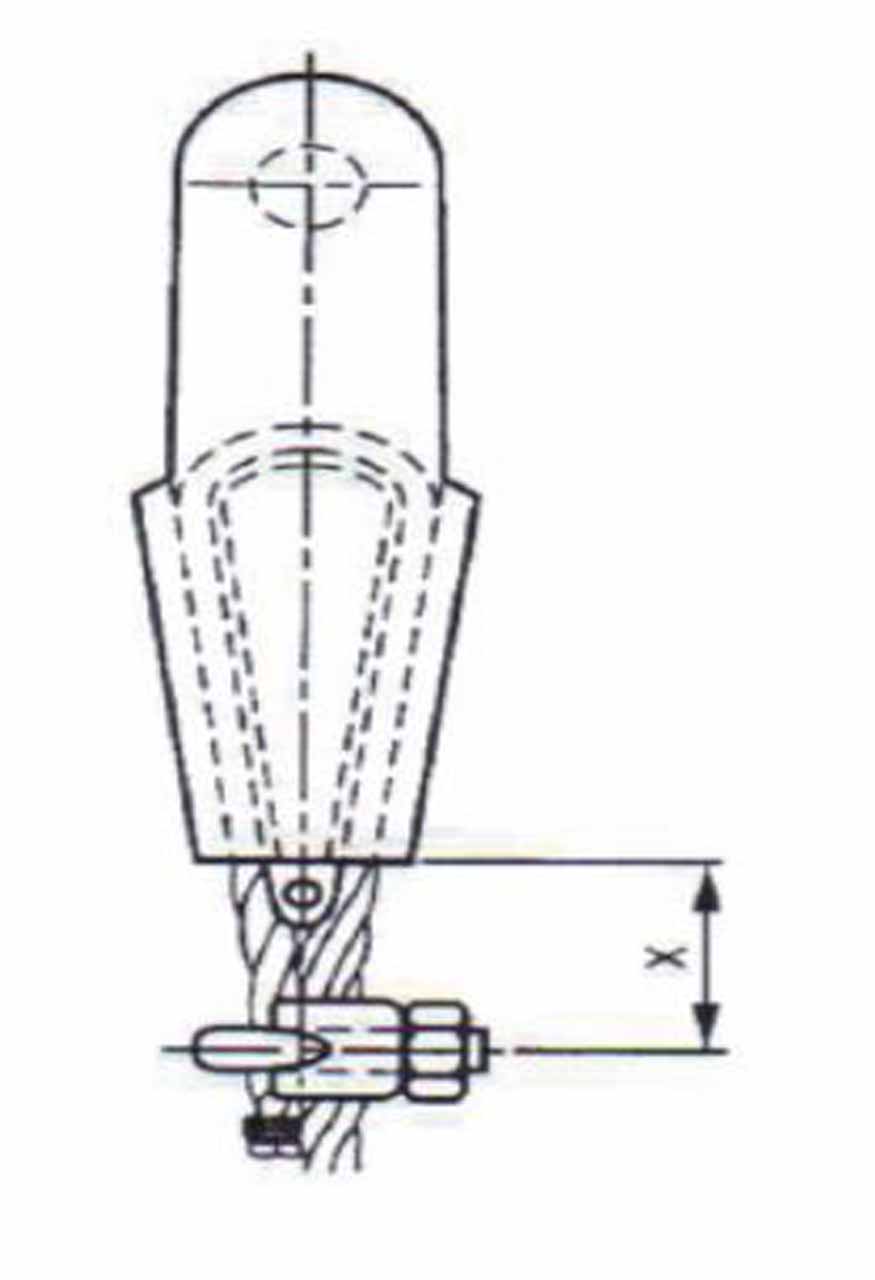

There are conditions to follow regarding the fixing of the ropes to car, counterweight and suspension points. One of these conditions is that the mentioned suspension points should be able to bear at least 80% of the breaking load of ropes. Ropes should be connected to suspension points using socket-type termination. The place of the connector that is used for terminating the rope is determined according to wedge. Ropes cannot be connected with the cringle (fairlead) method.

Traction of suspension ropes should ensure that the car stops without slipping at the parking level while it is loaded 125%. Also should be able to reduce the speed to less than or equal to the speed considered in the buffer design, emergency braking of the empty or rated load car must be ensured, and if the machine has stopped or the ropes have slipped on the traction sheave, the car or counterweight must ensure to stop before it reaches a dangerous position.

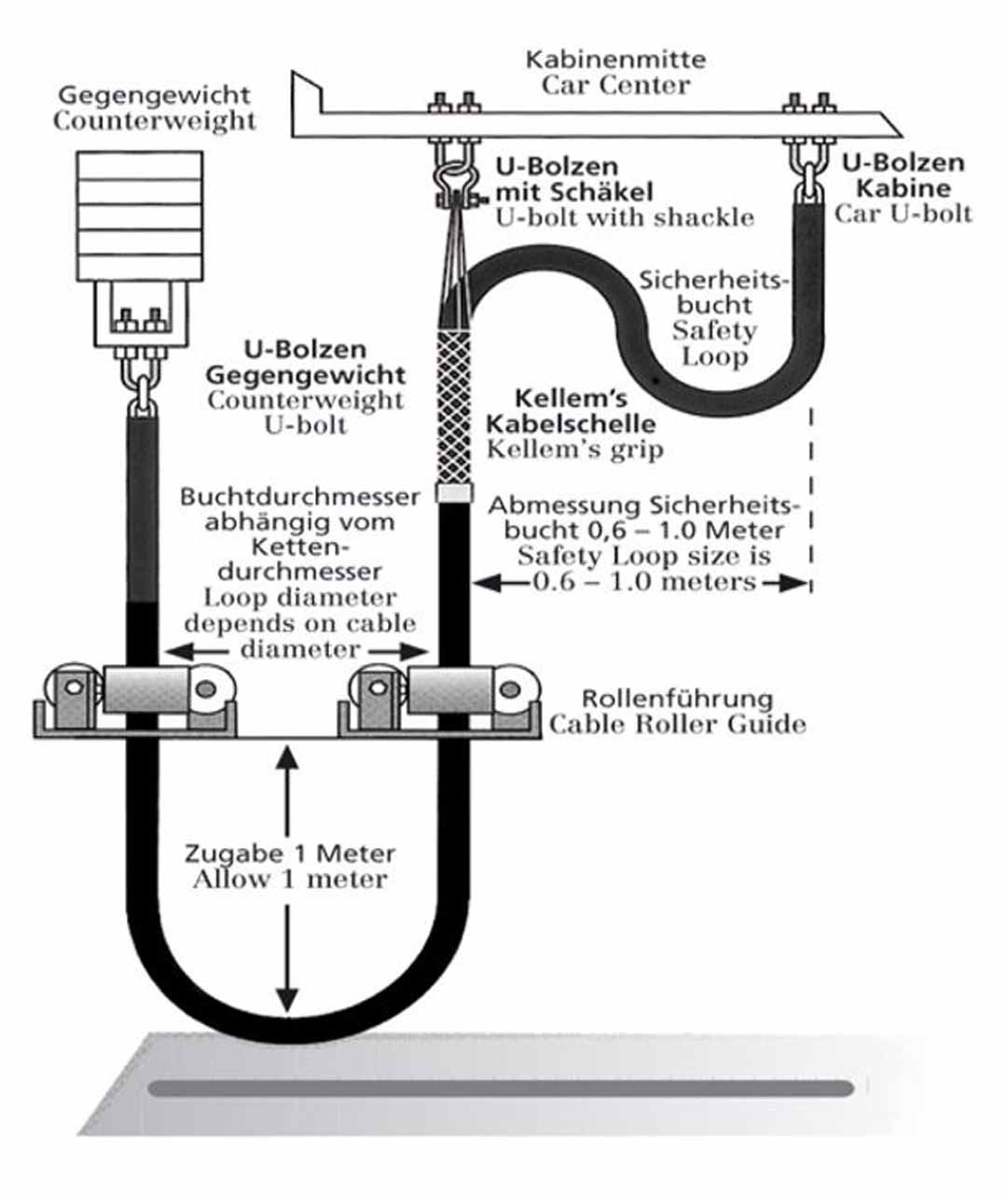

In order to balance the tension of suspension ropes, the ending of at least one of the ropes should have an automatic system. If spring is used to equalize the tensions, the springs should operate under tensile compression. When there is abnormal elongation or loosening rope, a safety means should stop the lift when one of the ropes extends if two ropes are used for the car suspension. In hydraulic lifts and positive traction lifts, a safety means must stop the machine if there is a risk of rope loosening. Normal operation should not occur after stopping; the device used to adjust the length of the ropes should not loosen by itself after the adjustment.

In lifts that do not exceed 3 m/s speed, the balancing means used to ensure that the rope traction and motor power is sufficient may include chain, rope and belt. However, at rated speeds exceeding 3 m/s, balancing must be achieved with a balancing rope. An additional tensioning means must be provided for those exceeding a speed of 3.5 m/s. Tensioning means should stop the machine through electricity safety contact. If a balancing means tensioning device is used at speeds exceeding 1.75 m/s, it is sufficient to guide it near the loop.

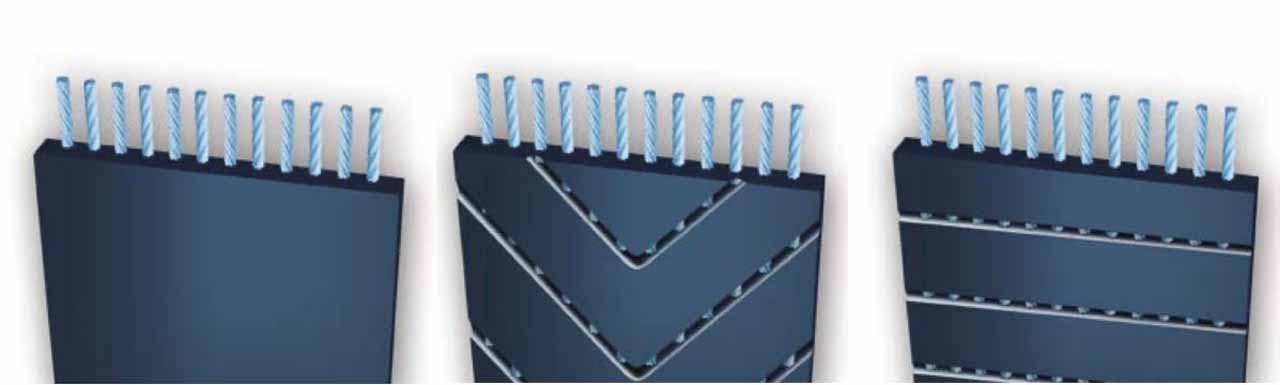

Today, apart from suspension ropes defined in EN 81-20, polyurethane-coated steel core belts can also be used as suspension elements for lifts. Belts are tested by Notified Bodies and verified that they meet the safety requirements defined for suspension ropes in EN 81-20 and 50.

The main issues that are checked and verified during the test and certification process of the belts are the physical properties of the product, the safety factor, breaking load, traction ability, life cycle, number of runs and type of termination. When the belts are to be used, the directions in the user manuals and the Notified Body report on issues such as the type of sheave to be used, the number of turns, the number of bendings, the maximum allowable nominal speed, the service life and the replacement criteria must be strictly followed.

I hope that my readers will find these matters beneficial. Have a healthy day.

Get more of Elevator World. Sign up for our free e-newsletter.